New Product

P321's Elegant 6-bolt Conversion System

Project 321's G2 hubs dealt with Centre Lock poorly; as in, not at all.

Mark Wells, P321's manager of business development, told me the company's product team wanted to make hubs that would more seamlessly deal with both rotor mounting systems; Center Lock and 6-bolt. The team discussed the pros and cons of each system, and assorted adapters, and they were left to conjure a way forward for their upcoming G3 hubs.

The next morning Mats Lepowski, P321's Chief Technical Officer, and lead design engineer, presented his idea, mocked up in a CAD program. It was a brilliantly elegant solution that was vastly better than any that have come before. At this point the engineering team set to work, making prototypes in-house

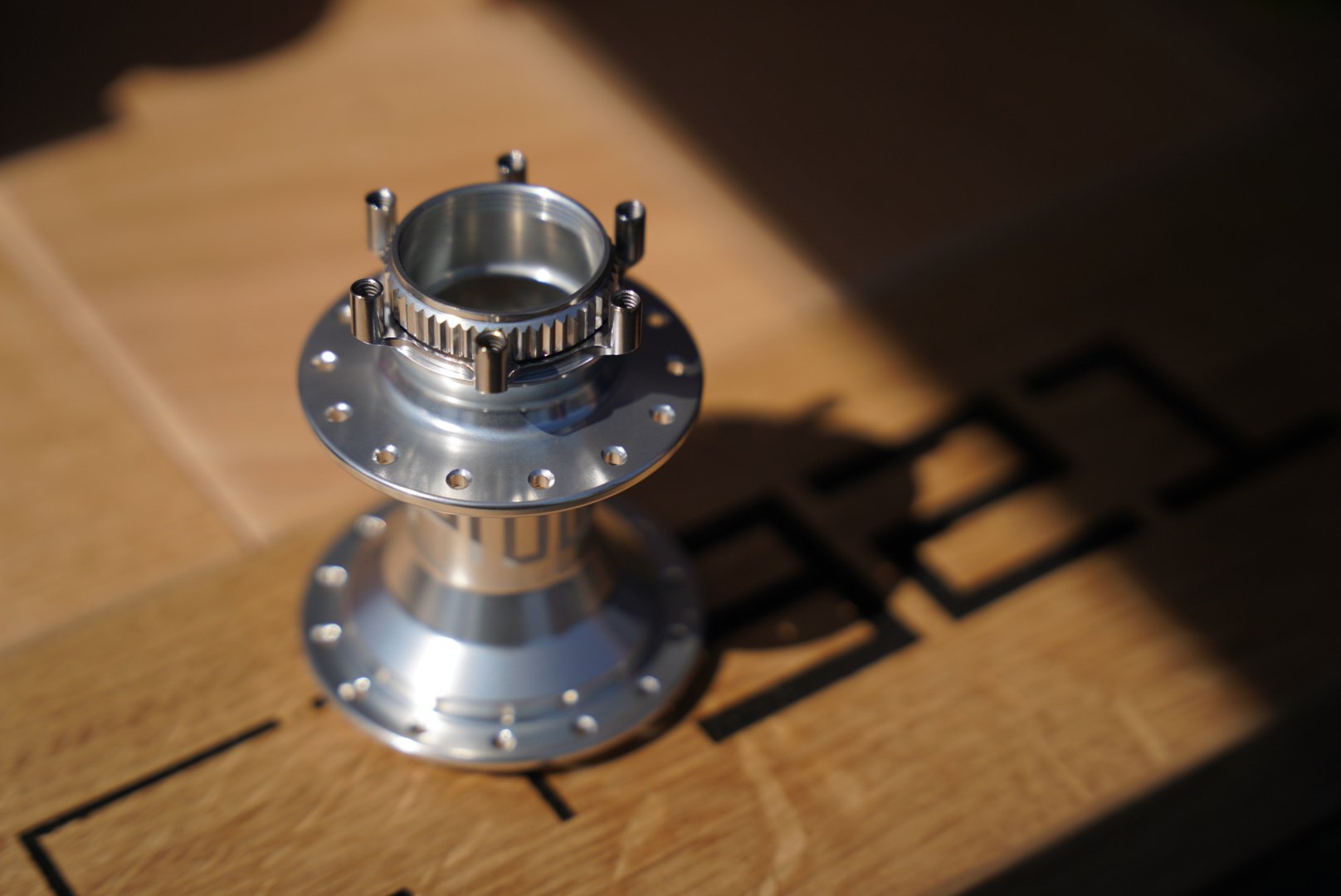

The stainless steel collet supports 6 threaded stainless-steel studs that nest in the aluminum flange (not pictured).

Mats doesn't come from the world of bicycles. His experience is in the automotive world, in particular working on bearings, drivetrains, and designing one-way clutches. Perhaps the absence of preconceptions allowed him to come up with such a simple and elegant solution so quickly.

These two pieces convert most Center Lock hubs to 6-bolt with virtually no compromises and several advantages over traditional 6-bolt designs.

The key to 6 Lock is the collet ring that attaches to a slot machined into the circumference of the hub, inboard of the splined portion of a Center Lock hub.* This stainless steel collet also cradles six m5 threaded sleeves which are then surrounded by an aluminum flange, drilled with six holes to accept the collet.

*This slot apparently serves no functional purpose for affixing rotors; it's simply there for machining purposes, allowing shavings to dissipate more effectively. A happy accident.

Another view without the flange installed.

Once installed, the hub appears to be a normal 6-bolt hub. After the rotor is in place and the bolts are properly torqued, the rotor and the collet sandwich the aluminum flange firmly into place. Once the six bolts are installed, nothing else is required, meaning you can ditch your lock ring.

In the example presented to us at Sea Otter, the black flange contrasts with the polished and anodized hub to highlight how everything goes together. When the flange and hub are the same colour, the system appears to be one piece.

As Mark Wells explained to us, there are several other benefits to this system. Instead of steel bolts threaded into an aluminum hub shell, you'll have stainless steel threads, which are much more durable and resistant to cross-threading. In the unlikely event that you damage the stainless steel threads, you can order an inexpensive replacement collet ring. After you slide the new one in, your rotor interface will be as good as new. Another advantage is that the collet transfers braking forces directly to the splines, meaning the bolts aren't subject to shearing forces; they are only there to sandwich everything together.

Mark Wells and Trevor Young, P321's CFO, keen to push Project 321's innovative hubs forward.

Obviously 6 Lock will be available on P321 hubs and it won't be immediately available for purchase in the after-market but I suspect that will come. 6 Lock will work on any hub that has been designed to Shimano's Center Lock specifications. If the channel that sits inboard of the splines isn't present, or isn't sufficiently deep, there may not be room for the collet. It would be wise to determine compatibility before dropping some cash.

All that is required is a Center-Lock hub that has been made to Shimano's specifications, assuming P321 makes the parts available for sale for owners of other hub brands.

Project 321 Facts

- The business began 17 years ago, manufacturing gas caps for motos.

- Founder Jake Liles recently sold to North Arc Precision, a business primarily working in the firearm field, producing after market triggers under the Trigger Tech name.

- The company is now Canadian owned and production will move to North Arc's 42,000 sq ft facility in Mississauga Ontario

- Project 321 Hubs are known for high engagement and a low friction design that spins faster than most others.

- Moving forward, hubs and the 6-Lock adapter will be made in Canada.

- G2 hub production has been discontinued, but service and spare parts will continue to be available. All existing warranties will be honored from the new Canadian headquarters.

- A brand-new G3 hub is currently in the final stages of testing and its official release date will be announced this quarter.

P321 will be releasing this high-engagement titanium free hub body in conjunction with the G3 hub. The system his 2.5º engagement and is also suitable for eMTBs.

Obviously this system isn't yet proven by independent testers or on the open market, but the design looks to be rather foolproof. There could be manufacturing irregularities or design issues (not that we would expect that from P321), but barring that, this interface should replace any that have come before, with a vastly improved and simplified interface to convert Center Lock hubs to 6-bolt.

Comments

Dave Tolnai

1 year, 11 months ago

I have 2 questions:

1) Are bolt hole diameter tolerances now in the picture?

2) Does P321's parent company donate to the NRA, CFA, any other gun absolutism organizations?

Reply

Privateer

1 year, 11 months ago

This comment has been removed.

danithemechanic

1 year, 11 months ago

Yeah the fact the company has been sold to a firearm company got me feeling weird too.

I also had to have a third look at the pics as i couldn't figure out how a stainless steel ring would be removable from a space behind a bigger diameter part.

Then i saw the ring is split.

Reply

ZigaK

1 year, 11 months ago

The parent company apparently sells aftermarket triggers?

https://www.grandviewoutdoors.com/guns/shotguns/new-trigger-makes-ar-15s-nearly-full-auto

Reply

Brian Tuulos

1 year, 11 months ago

Why spend $80 on a fancy adaptor when you could just spend the money on a nice shimano centerlock rotor and have proper fitment?

Rotors are consumables. And I'd argue they are better rotors vs 6 bolt for various reasons. Cheers.

Reply

Privateer

1 year, 11 months ago

The flanges are going to be included with the hubs, and the point is to give you options to fit whatever rotor you like. Center lock, or, 6-bolt with true 6-bolt retention. They weren't designed with the intention to sell them on their own.

Reply

[user profile deleted]

1 year, 11 months ago

This comment has been removed.

Sethimus

1 year, 11 months ago

the nice ones don‘t come in 220mm

Reply

Timer

1 year, 11 months ago

Shimano rotors are, as far as I'm aware, not available on the thicker widths recommend by some brake manufacturers.

Reply

kcy4130

1 year, 11 months ago

Smart and simple. I like it, but I'm wondering what it'll cost. That ring takes a lot of machining!

Reply

Privateer

1 year, 11 months ago

Target pricing communicated at the show was $650 USD for a hubset including the 6-lock flanges with the possibility of some upcharge for colour and endcap colour customization. Firm pricing will be released when the hubs launch.

The flanges will not be sold separately off the bat as many manufacturers don't hold right to Shimano's centre lock blueprint and fitment can't be guaranteed on other manufacturers hubs.

Reply

Brian Tuulos

1 year, 11 months ago

Rotors with aluminum carriers such as centrelock IMO are:

much more stiff and less prone to bending (especially in larger diameters) The carrier can be 6mm thick in places, VS 1.7mm thick steel on a conventional rotor

Probably shed heat better due to aluminum carrier

I'd bet ice tek actually works and runs cooler than conventional rotor

Look hella cool

_______

6 bolt is better for using adaptors (eg142 --> 148) , and riding your bike across the gobi desert and you want to carry minimal tools.

Reply

MTB_THETOWN

1 year, 11 months ago

You forgot that centerlock is both lighter and faster to swap out.

6 bolt is also handy when have multiple different hubs on the same bike and want to space the rotors with shims so you don't need to adjust the calipers each time you change wheels.

Reply

eriksg

1 year, 11 months ago

I wonder if 6 bolt is also environmentally better--rotors are consumables after all so you're recycling or tossing them when they're used up. For 6 bolt you have a single piece of steel, rather than a mix of steel braking surface and aluminium carrier. And it seems like there should be less waste in production too. But maybe that's not true.

Reply

Kos

1 year, 11 months ago

Looks brilliant. Once proven and available aftermarket, I'd add one or two to my "road trip spare kit" because why not?

I've got a set of P321 hubs that have served me well.

Reply

nothingfuture

1 year, 11 months ago

Please, pretty please, P321- do a 157 w/ HG and make this guy happy.

Reply

Cam McRae

1 year, 11 months ago

That seems quite relevant currently. Hopefully they will.

Reply

Privateer

1 year, 11 months ago

157 and HG and was on the table at Sea Otter. It will be a standard offering.

Reply

[user profile deleted]

1 year, 11 months ago

This comment has been removed.

Privateer

1 year, 11 months ago

Not everyone wants to use the lockring. For ardent 6-bolt holdouts, that's often the crux.

Also, if you cross thread or strip your center lock threads (very rare), this flange keeps your hub in the game! Problem is seldom, but for the seldom who encounter it, it's a big problem.

Reply

[user profile deleted]

1 year, 11 months ago

This comment has been removed.

Privateer

1 year, 11 months ago

Some say they come loose. Others say they they are less serviceable trailside as you need a BB tools or similar, opposed to the T25 available on any multi tool.

I am ambivalent myself, I'd ride either.

Reply

[user profile deleted]

1 year, 11 months ago

This comment has been removed.

JVP

1 year, 11 months ago

I have a couple friends that absolutely loathe the perceived rocking of centerlock (brakes on, rock bike forward/back). Of course this doesn't matter when riding, but it's a thing...

Reply

[user profile deleted]

1 year, 11 months ago

This comment has been removed.

BarryW

1 year, 11 months ago

It's funny to me how excited some people are by this hub.

It seems there is a perception of centerlock being bad, more than a reality. And centerlock to 6-bolt adapters are cheap and readily available. What problem is this actually solving?

Sure, I get the 'brakes on rocking back and forth' thing, but who cares? I'll bet your car does that in the right circumstances and it's not an issue.

Reply

DBone57

1 year, 11 months ago

I hear the 'brakes on rocking back and forth' thing and it has just never happened on my DT hubs. Now I have never owned a different manufacture's CL hub, so maybe it's a thing on other brands, but not a DT. I love CL but just wanted to try a Trickstuff rotor which forced me to use the included with my wheelset DT adapter which also does not rock back and forth at all.

Reply

[user profile deleted]

1 year, 11 months ago

This comment has been removed.

ohio

1 year, 11 months ago

I don't get it either. I've run the DT Swiss centerlock adapter which is pretty cheap, nicely simple, requires no bolts to lose or tighten or torque, no tools beyond the standard lockring, and they worked perfectly fine. Additionally, most rotor manufacturers now make centerlock versions. I'm running SRAM HS2s in centerlock so no longer need the adapters, and am able to get the thicker format.

Reply

Cam McRae

1 year, 11 months ago

I use the traditional adapters but I don't find them to be an elegant solution. Some do indeed rock and some have warnings about using rotors larger than 210 mm (which likely means all should). They work, but for my they are used in a pinch rather than by choice. This system however provides a solution that appears to be equally effective and secure for either interface - and to me that has significant value. Part of that comes from my need to swap things out between different test bikes and adapt things to work together. I also see value in resale and longevity because of the replaceable nature of the interface.

Reply

Kenny

1 year, 11 months ago

> Another advantage is that the collet transfers braking forces directly to the splines, meaning the bolts aren't subject to shearing forces; they are only there to sandwich everything together.

The forces on the bolts are no different than any other arrangement. They are still what attaches the rotor to the hub assembly and forces are transmitted via that clamped interface. Also, given that, like in any arrangement, they should not see shear load unless they are not torqued correctly. They are clamping the rotor to the mounting face of the hub.

Reply

Privateer

1 year, 11 months ago

In the current design, the rotor sits on the collet posts that sit proud of the flange, and the bolts are out of the torque path of the rotor. Even if the bolts loosen, they will not be in shear. The design is totally different than any other, but it's hard to tell until you actually see the thing in person.

Reply

Kenny

1 year, 11 months ago

Be that as it may, the rotor is designed for the load path to be through the clamped surface, not the bolt holes.

It's like a wheel on a vehicle. The fact that if you left all of the "lug nuts" loose the force would be against these threaded inserts is sorta beside the point because it's not a valid use case and something is like going to get mangled either way.

It's not like you can actually ride around with all the rotor bolts loose so it's irrelevant. If installed correctly the load path is the same so you can skip the straw man argument. :)

Reply

[user profile deleted]

1 year, 11 months ago

This comment has been removed.

Privateer

1 year, 11 months ago

Bolts don't shear no, but they can definitely tear away from the flange if run loose (and are in shear). Mangle is a great word for what happens to a traditional 6-bolt flange. I've seen it, albiet seldomly.

Reply

Dustin Meyer

1 year, 11 months ago

So that means that it uses different bolts than standard? M4 instead of M5?

Reply

Privateer

1 year, 11 months ago

The model pictured is M4, but the crew is also contemplating a version that will employ standard M5 rotor bolts.

Reply

JVP

1 year, 11 months ago

Any word on whether P321 still planning to make a quiet driver? The only quiet options for XD I know of are Onyx, Stealth and Newmen. Probabl some OEM stuff, too, if I could figure out which ones are reliable. All those have their various issues ranging from weight, cost, reliability, availability, so hoping P321 gets back in the quiet game!

Reply

IslandLife

1 year, 11 months ago

Check out Tairin's new S1 hub... pretty cool stuff!

https://www.tairinwheels.ca/product-page/tairin-s1-rear-boost-hub

https://www.tairinwheels.ca/silent-hub-technicals

Their Instagram has quite a bit of good info as well - https://www.instagram.com/tairinwheels/

Reply

LWK

1 year, 11 months ago

so... you're looking for a cheap, light, high performance hub? legend has it you can maybe get two of those things in any given bicycle part, but very likely not all three

Reply

JVP

1 year, 11 months ago

True that. But with some of these we’re talking heavy, expensive and unreliable. Or not available in North America.

Reply

Michael

1 year, 11 months ago

I keep asking but they have not confirmed the silent hub version. I am one of those customers that has never had an issue with them and I love them. I have 2 sets in the fleet. Having said that I also have a non quiet version and even that one is vastly quieter than most other brands. If anyone has any P321 G2 boost hubs in the high engagement version XD or HG and they don’t want them anymore hit me up!

Reply

DBone57

1 year, 11 months ago

Interesting and while I do like new designs and innovations, I have to wonder what is wrong with my DT Swiss CL to 6 bolt adapters that I am running on my XMC 1501s as they work perfect with my 6 bolt Trickstuff rotors?

Reply

Please log in to leave a comment.