Review

Project 321 Hubs - Reviewed

Perfection? Not quite...

The Project 321 hubs were not the flawless high-end hub set I expected from the company. They started out fantastic, it got cold, there were performance issues, I rebuilt them, and they have been excellent for all the months since. I'm not the only person who experienced an issue, not all issues were as quickly and easily resolved as mine. Project 321 says that less than 0.1% of the hubs they sold have had an issue and everyone has been taken care of but I mention it up front as I will be recommending the 415 USD hub regardless.

Simple to service, Japanese made EZO bearings that spin as smoothly as day one, and a quiet (or loud) 2x6 pawl arrangement that powers a 72-tooth driver for lightning fast 216-points or 1.66° of engagement; it's clear where P321 has gone right, so I'm going to start by talking for a couple of paragraphs where they went wrong.

Pretty in pink and a lot of other colors - ten finishes in total. The Boost front hub is easily adapted to 15x110 and 20x110.

The rear hub is where the magic happens. Choose between a 2x6 pawl configuration for 216-points / 1.66° engagement or 3x6 pawl configuration for 144-points / 2.5° engagement.

Project 321 has been making hubs for a number of years but the previous models featured proven Industry Nine internals. A new in-house drive system was released with the intention of delivering faster engagement and the option for quiet or loud freewheeling depending on which set of magnetic pawls was installed.

My issue started when the temperatures dropped and my hub started skipping periodically. I traced the problem to the DuMonde Tech freehub grease that P321 chose for lubricant. I flushed the hub, replaced the grease with freehub lube, updated my teardown piece, and carried on enjoying the product. Swapping the grease for oil does make the quiet pawl set louder, though still very quiet for a high-engagement pawl hub. The loud pawl set is screaming loud so there was no change of note*.

*I'm certain one could calculate the change but it would be pointless; akin to tabulating the number of times a serial liar tells a fib over a 500-day period.

The hubs have been a constant through various setups... (Photo: AM)

...a range of conditions...

...and forks from Manitou, Fox, and Suntour. (Photo: AM)

Not all P321 owners were so lucky. Some needed a new seal to keep oil from leaking out of the hub, where this was not a problem with the grease. Some needed new pawls. Some needed a new drive ring. As mentioned earlier, P321 looked after everyone who had an issue but it took too long to do so.* The offending parts were previously outsourced but P321 decided to move production in of the pawls and drive ring in-house extending the delay.

*the company was in the midst of a move during this time

It's likely that these travails have cost sales. There's a cautionary tale for any small brand about testing in every condition that your product will be sold into. The length of time some riders waited to get their expensive hubs sorted was too long and yet I know of riders who will be customers for life thanks to how hard P321 worked to make everything right for them.

And now, on to the hubs.

Quiet VS Loud

According to Project 321, the loud pawls have a slight increase in drag over the quiet version but it's not something I can notice in the work stand or on the trail. My verdict is to choose your pawl preference and roll with it. Based on their testing, compared to the leaf-spring-loaded pawl system they used previously, P321 claims a 68% reduction in drag for the quiet pawls and a 51% reduction for the loud thanks to using magnets instead of springs.

The quiet pawls are not silent in the same vein as a True Precision or Onyx hub but even with oil installed instead of grease, they are the lowest decibel high-engagement pawl option on the market. I slurried in a dab of Slickoleum with the hub lube and that quieted the hubs down without introducing any skipping issues.

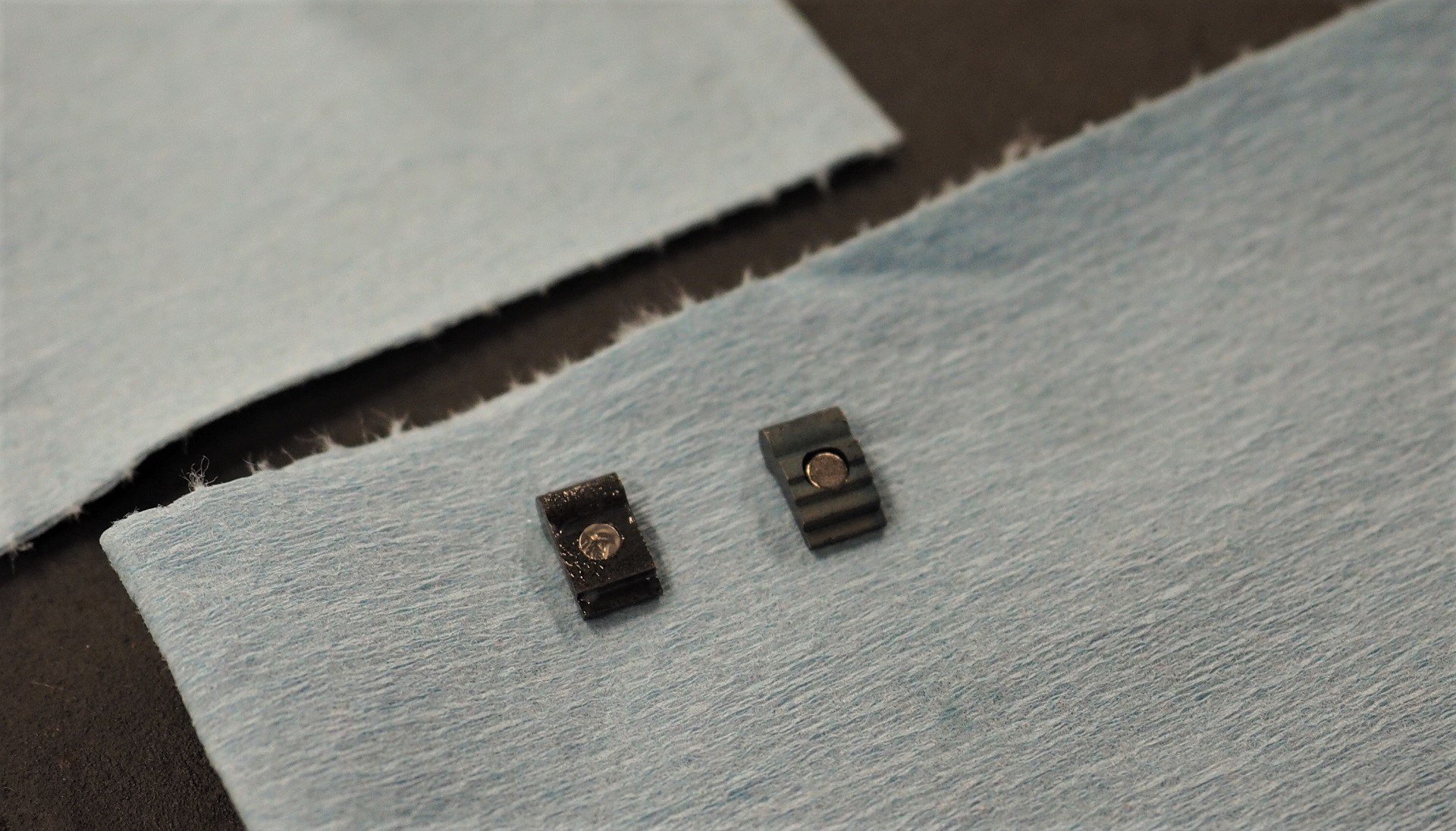

The magnetic pawls are lightning quick to swap for quiet or loud performance with the same 1.66° engagement. (Photo: AM)

Magnetic pawls mean no springs to lose or damage during service or to wear out over time. (Photo: AM)

I spent most of this test on the quiet pawls and even with the grease issue, and associated skipping I experienced, there is no wear on the pawls or driver after many months of hard use.

For a visiual breakdown on how the drive system works check out P321's graphics here.

Bearings & Tension

Every part of the Project 321 hubs is made in Oregon except for the Japanese EZO bearings. I'd never heard of EZO before doing this review but my takeaway is that I'll be trying to source them for replacements in any of my personal hubs in the future. Short of going Full-Chris-King and building their own stainless steel bearings in-house, I've never ridden bearings that spin this smoothly for this long.

I'd recommend going with Project 321's standard EZO bearing package over the Enduro ceramic bearing 'upgrade'. (Photo: AM)

Tight tolerances and quality materials have them rolling as smoothly as new, on the stock light-grease, after a wet winter of use.

There are two schools of thoughts on hubs using cartridge bearings. One is to preload the system using the compression of the fork or frame axle being tightened down and the other is to allow for fine tuning of that bearing preload using a threaded collar.

I haven't had any issues with cartridge bearing life or drag from hubs using compression like the Industry Nine Torch, so personally, it's not a must-have feature. I know a lot of riders who wouldn't buy a high-end hub without the feature and there is certainly no negative to being able to fine tune bearing adjustment.

P321 spaces out their bearing adjuster such that it can be easily adjusted without removing the rotor. Thank You. (Photo: AM)

I have adjusted the tension twice over the course of my test which is similar to my experience with King hubs over the same period.

Engaged

Project 321 recommends the 3x6 configuration for Tandems, E-Bikes, and riders over an arbitrary 275-lbs. Both configurations carry a 3-year warranty on all the drive components and if you're 274-lbs in your birthday suit I still wouldn't hesitate to order the 2x6 system. It's still a ridiculously fast 2.5° engagement for a pawl hub.

The 1.66° and 2.5° engagement options use different drive components - other than pawls - so your choice must be specified at the time of purchase.

One other feature of note with the drive system is that it is backward compatible to the past generation P321 G2 hub series. The old system engages fast but for a trials rider, poacher, or someone who prefers the sounds of nature over the whir of a loud hub that may appeal.

This begs a question. If the older generation Project 321 hubs used Industry Nine internals, and the new drive system is compatible with the older hubs, does that mean that I can put the 1.66° P321 guts into my Industry Nine Hub?

Other than flushing the grease early in my test I had not cleaned out this hub until writing this test. It was all good but my persnicketiness calls for a maximum 100hr service interval on the drive mechanism of a pawl hub.

Project 321 hasn't tested for this configuration but it absolutely will physically work to install their drive ring and freehub into a Torch hub. They can't recommend it and do not extend a warranty on drive parts installed into another manufacturer's hub but the small parts are available separately.

Since I swapped to oil in the freehub I haven't suffered a single slip, skip, or other hub related drivetrain issue. That meets my expectation for premium mountain bike hub. If I have to think about it out on the trail then it's not doing its job.

Final Thoughts

A rider who doesn't care about hub engagement can maybe still appreciate the Project 321 rear hub for the quality and ease of service. I love fast engaging hubs and wouldn't personally spend on a high-end* hub that has more than 3° of engagement. That's my bias. And given that bias, I love these hubs. I don't need to have access to a full bike shop, machine shop, a ton of experience, or an engineering degree to fully rebuild them and there are no expensive tools required to do a full overhaul including the bearings.

As to my issue early on, Project 321 says less than 0.1% of the hubs they've sold have had the issue and, of course, everyone has been looked after. Performance has been flawless and that's what I'd expect if I ordered a set of hubs today. Which I would certainly do if I needed to replace the Industry Nine hub I run on my lighter single speed wheelset.

*Actually, after testing Bontrager's 300 USD Line Comp wheelset I can't can't think of a reason I'd buy any hub with more than 3° between engagements.

The removable reducer caps on the front hub stay put more tenaciously than most. The Boost front hub can be swapped between 15mm x 110mm and 20mm x 110mm. (Photo: AM)

Made in Bend Oregon with house-made parts, except for the wicked Japanese EZO bearings, these Project 321 hubs command a premium price - 415 USD rear | 185 USD front.

That's a lot of money and a set of well maintained Bontrager Line Comp wheels, potentially with some EZO bearings installed at service time, make a compelling min-maxing counter-argument.

But, high-end hubs are one area on my bike that I've long been willing to invest money, from my 2000 Profile Racing hub onward, and if they're in your budget I* think they're a great buy.

For more information please check out Project 321's website here.

*For a second opinion please see Tim's We Are One review here.

Comments

edmclean

5 years, 10 months ago

I've tried loads of different hubs over the years and have come to the realisation that Hope hubs are just the perfect compromise. I don't believe there is a better value for money component in the bike industry.

Reply

[user profile deleted]

5 years, 9 months ago

This comment has been removed.

Shoreboy

5 years, 9 months ago

I would say that my investment in CK hubs 14 years ago was the best value for money bar none. Started off life as 135mm x 9mm, now are are on my current ride at 142mm x 12mm. Have only taken them apart once to repack the bearings, mostly because I felt I should, not because it was needed. Having ridden on them for that long, im not sure id feel right with a silent hub and without the 'angry bees' following me down the trails.

Reply

Endur-Bro

5 years, 9 months ago

The silent hub is a neat experience. Although I'm always wondering if now I'll startle an animal.

Reply

Michael

5 years, 10 months ago

I also suffered the issues with the initial set of these. Swapping to oil solved the skipping issues for me as well. I still bought another one and I’d happily continue buying them despite the high price. They roll like mad and the silence is bliss. It should be noted unlike other silent or near silent hubs on the market these are much lighter in weight. One also saves time and money (as mentioned; no special tools) in their ease of service.

Reply

Andrew Major

5 years, 10 months ago

Hi Michael, I’ve never been a gram counter but you are absolutely correct that the weight vs engagement vs noise ratio is best in class for those weighing tires on the XC Bike or trying to drop unsprung weight on the Dual-FS. Thanks for mentioning it.

I’m glad I’m not the only one in the experienced-an-issue but would recommend them heartily anyways camp. I wasn’t sure how that would come across when writing this.

Reply

Tadpoledancer

5 years, 2 months ago

Did you ever try to put the quiet 321 hubs on your I9 hubs, Andrew? I've got som Torch hubs that are working well, but I'm getting tired of not experiencing the quiet of the forest when I'm out riding.

Reply

Andrew Major

5 years, 2 months ago

I did not - it’s theoretically possibly but requires a new drive ring, a rare I9 drive ring removal tool and a MASSIVE cheater bar.

Reply

Tadpoledancer

5 years, 2 months ago

Haha, alright. Doesn't sound like that's worth the trouble.

Reply

Andrew Major

5 years, 2 months ago

A little bit of Dumonde Tech freehub grease slurried with their freehub oil quiets an I9 down a lot - but too much could cause the pawls to stick or slip. That’s how I quieted down my I9.

Reply

Tadpoledancer

5 years, 2 months ago

Great, maybe I'll try that. How long does the effect last? I guess it wears down over time.

Reply

Andrew Major

5 years, 2 months ago

It’s one of those YMMV situations but I9 Hubs are so quick to pull apart that doing a quick cleaning and lubing the pawls and drive ring isn’t even a one beer job.

It pains me a bit how few people open their I9 hubs up to drip some lube in once in a while - when they’re really dry you can hear them screaming for mercy from a km away through the trees. But, at least they give a shout out when they need some love.

Tadpoledancer

5 years, 2 months ago

Haha, I'm feeling an immediate sensation of guilt here now, but I shall try to improve. Appreciate your feedback!

Reply

Andrew Major

5 years, 2 months ago

Ha! I try not to tell anyone other than my kid how to treat their toys - but I know your hub will love you for a quick bit of service.

Check that the bearings still spin too. Last time I had mine apart I popped the seals and replaced the grease in the accessible ones. It’s super quick and prolongs the time before the big service.

crimedog

5 years, 9 months ago

I've been drooling over these hubs for over a year now. I was really pleased to see We Are One offering them with their wheelsets (which I have also been drooling over for quite a while) but they have stopped offering them. Does anyone know why?

Andrew, thank you for including the notes about the problems people have been having. That honesty and the teardowns is why I like this site so much.

Reply

grimwood

5 years, 9 months ago

My experience was slightly different than Andrew’s. I’ve had 2 of these hubs and messed with the quiet pawls for a good while. Even switching to a thin chain lube, I still had lots of skipping. And I found lots of little shards or metal in the hub even after a few skips. One thing to note, it was less than ten degrees Celsius, but I still found it surprising. When I switched over to the loud pawls, I had no issues.

A couple things about this hub from my perspective. The loud option isn’t that loud. Like a hope. No where close to an I9. And these hubs are a joy to work on when the time comes. So easy and really well thought out design.

Bottom line, I’d buy them again.

Reply

Andrew Major

5 years, 9 months ago

My I9 hubs are quieter than the loud pawls in the P321 but that likely depends on lube?

Have you tried the newer made-in-house quiet pawls?

I never road the loud pawls with grease so my only comparison (apples:apples) is with oil in the hub. Did just changing the pawls to loud but with the grease still installed solve the issue for you? Still running grease?

Thanks!

Reply

grimwood

5 years, 9 months ago

Hey Andrew, I’m pretty sure my current I9’s shipped with oil instead of grease because they are crazy loud. The loud pawls I have in the P321 have a mixture of slickoleum and chain lube. I haven’t tried the tech grease.

I don’t know if I ever got a set of the in house made pawls. I was getting them through We Are One, but that was around the time that they dropped 321. So I’m not sure. If the quiet pawls worked, I would way rather have those.

Mike

Reply

Andrew Major

5 years, 9 months ago

Mike, you should touch base with P321. It seems everyone with the in-house made quiet pawls is having zero issues and they’d definitely trade you under their warranty.

Reply

JVP

5 years, 9 months ago

Andrew says this "and there is certainly no negative to being able to fine tune bearing adjustment." Your experiences are different than mine. How much do you weigh and how bad are your line choices?

The one fancy brand with preload that I used came loose too often. Always in the middle of a really deep ride, for some reason. Winter was a nightmare. Loose hubs = broken axles if you don't get on them right away. I'm really hesitant to run a hub with preload ever again. Hopes work great, then they get gritty and need service after a year of muddy rides, but they never die half way through a ride, and never skip.

That said, I really want quiet hubs without a huge unsprung weight penalty. Higher engagement seems less reliable (as DT has proven). Is the Project 321 3x6 option still quiet? I bet it's a more reliable option that is also less likely to skip in the winter (at least we ride in kneepads these days) when you're past due for a service. I'll always choose the more reliable option.

Edit: I should also say, great review!

Reply

Andrew Major

5 years, 9 months ago

Without you saying what make, model, and ~model year of hub you had issues with it's hard to give the best comparative answer.

For example, the only high-end hub I've ever had issues with breaking axles on personally where Chris King hubs when they used their 3-piece alloy axle system. Those axle ends snapped whether the hubs were loose or tight but they moved away from that system on mountain bike hubs over a decade ago.

I've had frustrations in the past with preloaders coming loose on a few different hubs (including the newer Chris King axle/preloader system) but I find a little bit of copper anti-seize on the threads solves the issue every time. I didn't put any anti-seize on the P321 threads but that's what I would do if I had an issue.

I'm ~185lbs and I've had zero issues with the P321 bearing preloader moving. Maybe it's the fine threads? Maybe it's the width (contact area) compared to most bearing preloaders? For what it's worth, I have not read anywhere of people having any issues with the hubs coming loose.

The 3x6 version uses exactly the same pawls so you can choose quiet or loud for either version of the hub. It's still a very fast engaging hub as well.

Thanks!

Reply

JVP

5 years, 9 months ago

Cool thanks. You're definitely not a waif, but a bit lighter. It was King hubs from many years ago. Broke the 3 piece axle, got that warrantied to a solid one, still had loosening. Sold them to a lighter friend who ran them on his DH bike for years without a single problem. I've had problems with other brands with preloaders, too. Shimano were the only hubs with preload I've run that were reliable, but obviously a different system.

Stealth, 321 and Onyx all have preloaders. Will wait for a few years to see which one has best crap weather sealing and no loosening.

Bigger + aggressive - smooth + pedal a lot + ride in crap weather = lots of dead parts.

I burn through chains and chainrings weirdly fast, so drivetrains are in misery under me. Switched to a $20 steel Race Face narrow-wide for that reason. The expensive SRAM xDome cassettes are magic, totally worth it. Last way longer, so about a wash cost-wise and lighter. Hope hubs rock.

That reminds me, I need to go replace my chain.

Reply

Alex D

5 years, 9 months ago

Shimano's new Scylence hubs might be your huckleberry. Silent and 230g in 148 spacing.

7.6D engagement, Micro Spline, Centerlock, and loose bearings could be downsides depending on your perspective.

Reply

Andy Eunson

5 years, 9 months ago

My new bike came with I9 hubs which skipped on the first ride. Pulled them apart and found the mechanism full of a blue greased. Wiped the grease mostly out and I’ve only had a couple skips science. I’ve wrecked a 32 tooth DT Swiss ratchet probably from too much grease. These things really don’t need much lubricant. Just a bare minimum. It’s not like the hub bearings that are moving while under load. There isn’t much load while freewheeling and while pedaling there isn’t any movement at the pawls or there shouldn’t be. Grease can keep the pawls from engaging properly.

I don’t know who greased the crap out of my hub. Either I9 does it that way or Santacruz who built the wheels did. It’s wrong.

Reply

JD

5 years, 9 months ago

I too had skipping issues from day 1 with my hub. It was grease-filled, and I started riding it in the fall, so the lower temps didn't help. By the time I had ascertained that it was indeed slipping, I had metal filings inside. P321 supplied replacement pawls and drive ring, but it was a little bit of an ordeal as they had to send the drive ring tool as well from the US to Canada, and I had to ship it back. All of that took some time, but it was over the winter and I had other bikes to ride, so no big deal. All in all, I was mostly happy with their service, and I'm pleased with the hubs since the fix. The hub is significantly louder now with the oil - yes it is quieter than my I9s, but with the grease it was damn near silent. I would consider buying again, but then again my Hopes and my I9s have been trouble-free...

Reply

mike

5 years, 9 months ago

Why do you not recommend the ceramic bearing option ?? And my last wheels I went with Tairin Shogun hubs , $$$ well spent. Much better product than the Hope from my experience.

Reply

Esteban

5 years, 9 months ago

"*While everyone has been taken care off, issues must be considered..."

"The rear hub is where the magic happens. Choose between a 2x6 pawl configuration for 216-points / 1.66° engagement or 3x6 pawl configuration for 144-points / 2.5° engagement." isn't that backwards?

"my hub started skipping periodically" How does that feels? Never happened to me, what to look for? This info is useful because not always are sounds instantly evident as to what is their cause.

Great to hear P321 stood up! Even after the aftermarket mods you did! They really need to sort that out if they plan to sell to regular consumers (don't feel so special, most mtb amateur and even some pro riders are neophites to the inner mechanics of their components; suffice for them to be of renown—or even better, utterly unknown—and in an anodized color (performance is a given past certain price level; companies that don't deliver at these prices don't last long), and having a basic knowledge of how parts are called, wich I'm certain happens easier, the unscholarliness of mtb by most riders I mean, because how products are named: "dude that's the FOX64! Totally far-out, rad yeaboi!". Maybe an idea for naming them based on intended activity? "FOX DH/Enduro/Trail Team/Pro/Race" (somebody tell RockShox and FOX and don't forget to tell them it was my idea and it would be very nice of them to send me a new suspension. Tell Öhlins too).

Ohhh, the loudness being switchable by inverting the prawls, maybe they're not planing on selling to the "commoneers" that don't know their mechs? I mean, "adjusting the tension twice", who'd have thought of that? Completely unheard of. And I know guys on Santa Cruces (yes, that's actually the spanish plural) that as I've mentioned, know jack of how their dentist set-ups works (one of them even "upgrading" parts—yes they're upgrades but at what level you really benefit from them?). _I_ didn't knew of user adjustable bearing hubs! What's that witchcraft? Changes drag?

And I can't stress this enough: a hub that needs a relube from the user right after buying it, is not a premium hub. "aside from my issue early on, performance has been flawless and that's what I'd expect if I ordered a set of hubs today", so, you actually expect to have to not only service, but improve, premium hubs if you ordered them today???

"The quiet pawls are not silent in the same vein as a True Precision or Onyx" without googling, because they don't use prawl systems, no?

"Project 321 recommends the 3x6 configuration for Tandems, E-Bikes, and riders over an arbitrary 275-lbs" if you ask them, it will most certainly not be arbitrary. Quite the contrary, that number must have arose from the science involved in creating this parts with such stress factors.

Why would anyone make a 2-prawl verions under a 3-prawl, two different markets?

Man, I'm so high.

Reply

Cooper Quinn

5 years, 9 months ago

I'm glad I read all the way to the end of your comment.

Reply

Eric Van Sickle

5 years, 9 months ago

I have a set of these on WR1 rims. I purchased the “loud” hubs and I had to call a Dustin to confirm that he did indeed send the “loud” hubs. They are near silent, really need to listen for them when riding. With the bike in a stand, one can definitely hear the hubs but not really on the trails.

Eric

Reply

pedalhound

5 years, 9 months ago

I have never met a set of pawl driven hubs that I can't break...albeit my history is mostly Shimano and spank hubs. I moved to CK many years back and have not had an issue since. I do like the idea of these...so easy to work on, but I won't spend that much without knowing I won't grenade it after a few months. The new XTR hubs look interesting too...gotta wait to see how they last in the real world through.

Reply

Andrew Major

5 years, 9 months ago

I’ve had enough issues with hubs that I see it as a really positive place to invest in a upgrade on my bikes.

I have had good experiences with high end pawl hubs from Insustry Nine, Profile Racing, and so far with Race Face on their Vault. On the lower end I have to give praise to Bontragers Line Comp.

Between my wife and I we have a few King hubs. The newest is ~6 years old and has all its original bearings. Yes, the bearings are expensive to replace but they last a long time.

I have a service tool which helps with costs.

I’m not saying anything bad about King - and even get the price.

I’m at a time in my life when fast/easy service counts for a lot and as you can tell I think these hubs answer all my needs/wants.

With your history it’s easy to play safe and get the 3x6 setup with 144 point engagement.

Reply

Please log in to leave a comment.