Fork DIY

Burnishing (Sizing?) Your Fork Bushings with RMS Tools

The classic instagram "fork burnishing" post shows someone manually pressing their CSU into its airless lowers with some effort. The next panel inevitibly shows them gliding down using only the force of gravity. This is followed by claims of incredible small bump sensitivity and even improvements in other travel points. These posts are compelling, partially because what they are touting makes quite a lot of sense.

WTF is Burnishing?

When I first heard of bushing burnishing, I assumed the process involved adding heat, after hearing of the term referring to brake rotors torched from long descents. In the dictionary, burnishing refers to polishing but from a machinist's point of view, it refers to a cold working process aimed at improving surface finish, making size and shape more accurate, increasing hardness and extending fatigue life.* The process aims to reduce the variation between peaks and valleys of the surface by stressing the material beyond its yield strength, essentially by pushing the peaks into the valleys.

*Obviously there is friction involved which means temperature is increased but no additional heat is added

Topher getting down to work on my Zeb at Obsession:Bikes in North Vancouver

Dropping the lowers.

The premise is that, once they are pressed into your fork, your bushings are rarely perfectly round or uniform. Assuming they started off that way, either the pressing process or imperfections on the inner surface of the fork casting are likely to alter that perfect circle.

Sticky bushings are often thought of as being too small but they are more likely to be slightly ovalized. When this happens a pressure discrepancy is created and oil flows to where the pressure is lower; the widest part of the oval. There are two downsides here. In a worst case scenario your bushings will press onto your stanchion on opposing sides, and lubrication will be directed elsewhere. Obviously, considering the goal of the interface between the stanchions and the bushings is adequate rigidity with as little friction as possible, this is less than ideal.

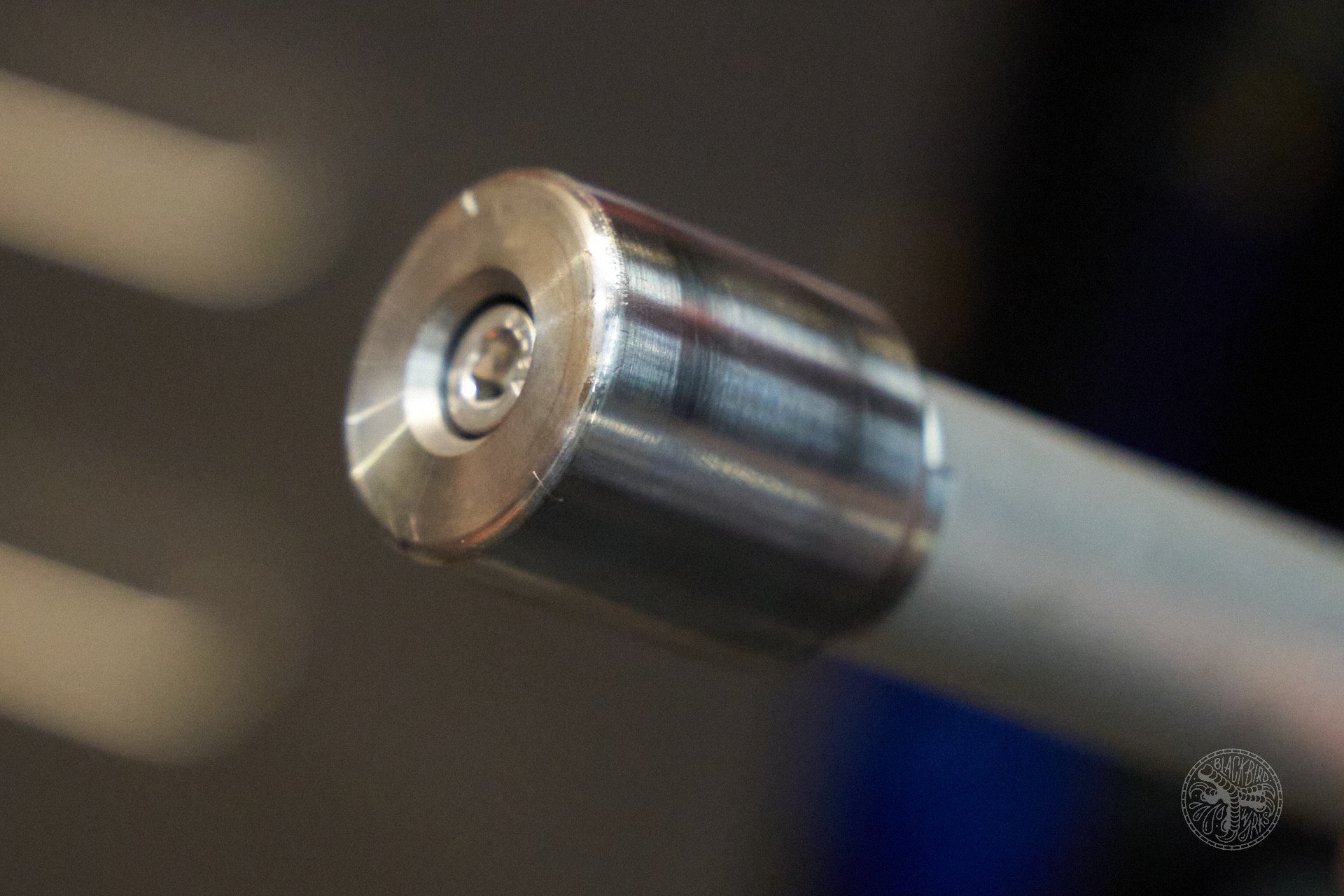

TheRelative Motion Burnishing Tool is very nicely made. Photos - Cam McRae

Full set with 32, 34, 35, 36, 37, 38, and 40mm heads.

Sizing tools can be manufactured to very high tolerances to be slightly larger than the nominal size of the bushings. Some of them come in multiple diameters for a given bushing size so you can gradually increase pressure the tool exerts on the bushing. The tools we are using, from Relative Motion Suspension, measure 100 microns (1/10th of a millimetre) larger than the bushing size, to a 5 micron tolerance. In this case that means 38.1mm.

The size and shape of the stanchions on this Rock Shox Zeb are remarkably accurate. My tool may not be calibrated to 10 microns, so we can't say 100% that this is accurate, but repeatability seems to be good and it measured virtually the same when rotated and raised or lowered. Photo - Cam McRae

You may question if this is a good idea, either to do it at all or to do it yourself. Some manufacturers, EXT for one, are known to do this at the factory. I was told by one suspension company that they do this, at least for their higher quality forks.* Their process begins clamping the fork into a stand that is equivalent to the ideal axle width they specify to ensure the stanchions are parallel. Then an automated double-headed sizing tool is inserted into the lowers to ensure the bushings are as round and uniform as possible and also perfectly aligned left to right. They do not recommend burnishing your fork on your own.

*I was asked not to reveal the source because this hadn't been accurately verified.

Topher getting down to it.

I was curious about how this worked at the Formula 1 level of MTB suspension; World Cup DH. I tracked down Mark Fitzsimmons who worked for Rock Shox from 1995-2002 and at Fox Racing from 2002-2019. A big part of this job at Fox was helping racers like Steve Peat and Greg Minnaar go faster, and to incorporate what was learned from the race team into product development, and vice versa. According to Mark, sizing bushings is a big part of making forks work as well as possible; "We walk a fine line there to a point where every now and then a rider who go, "hey, I'm feeling something." And we go, "no, we want that, it's okay."

Managing riders' sensations would play into the game as well according to Mark. "The cross-country riders could be more sensitive to it than DH, especially locked out, but downhillers, when the fork was loaded, they'd be so far into the overlap of the bushings, they normally wouldn't feel it unless they were unweighted and pulling over something flat." Obviously those of us just a wee step below World Cup level have different requirements. Having bushing rattle out of the box would not be ideal for someone hoping to ride a fork for three years or longer, but if you can change it several times a season or more, have at 'er.

Sizing bushings to the point where there was a little chatter off the top, when the fork was unweighted, ensures friction is as low as it can be without compromising control, making it clear how important free movement is for high performance.

The dirty work.

Spotted: a bushing.

This is How We Do It

I wasn't able to find much information on the fine details of using a burnishing tool, but the basics were pretty clear. Obviously the first steps involve dropping the lowers so you have access to the bushings, which means you'll be performing a lower leg service. I won't go into that here, but we enlisted Topher Masluk, mechanic extraordinaire from Obsession: Bikes to do the process expertly so we could take photos and observe.

Topher can drop and replace lowers in about twenty minutes so that part went pretty fast but once we got to the main event, things slowed down a little. I assumed, since the difference between the diameter of the tool and the inside of the bushings was merely 0.1mm/100 microns, that the process wouldn't require much force. In fact, Topher had to haul on the handle of the RMS tool to get the job done, which makes sense considering what burnishing actually accomplishes.

Step 1 - insert the tool into the lower with the appropriate (38mm) head attached.

It's quite obvious when you come in contact with the upper bushing because the tool is approximately 100 microns larger than the hole. It won't just slip through.

Topher blew off his cap and was beginning to sweat at this point. It takes some effort to exceed the yield strength of the bushing surface, which is likely PTFE (aka Teflon) on steel.

Once the top bushing gets the 100 micron treatment, which involves either rotating the handle in one direction, as though you are screwing it down, or back and forth with some downward pressure, it's on to the lower bushing. I'd say each bushing took close to a minute. After that the process had to be reversed with upward pressure needed to free the tool from first the lower and then the upper bushings. The fit is so tight it seems impossible, or at least extraordinarily difficult, to have the tool enter the bushing out of alignment, so it seemed the risk of damage was very low. The chamfered ends make alignment easy as well.

There was also evidence of burnishing on the surface of the tool.

It felt like a fork at this point. Trail time was needed to feel the difference.

Topher was in a rush to get somewhere so unfortunately we forgot to do the gravity test, to see if friction was reduced to the point that the uppers would sink into the lowers under their own weight, so the testing would have to happen on the trail.

Mission accomplished.

The Result

It's one thing to take a fork that feels like crap and make it feel better, but this burnishing was performed on a fork that already felt great. In fact I didn't think it could get much better. I was mistaken. Almost immediately it was obvious that the fork was moving more freely and reacting to bumps that previously were below the threshold needed to get the dampers involved. Bumps I used to feel at my hands disappeared. It felt at times as though I was on a magic carpet. Of course a service never hurts but this Zeb wasn't in need of attention. Aside from the sensitivity off the top, the fork reacted better to impacts at other points in the travel as well. The other day, after the burnishing, I thought my fork felt okay but not as nice as it had recently so I checked my dials and discovered my high speed compression was completely closed (I was likely sabotaged), and even that wasn't enough to spoil the feel. Once I removed a few clicks it went back to feeling great.

As I mentioned, I left the tool and attachments at Obsession:Bikes, and after a couple of weeks they looked like this. Obviously it's quite damp in this particular corner of the shop basement.

My own shop has its own moisture problems, but the tool had no corrosion on it at all after a couple of weeks down there. I'm sure five minutes with a Scotchbrite pad will clean these up as good as new but be careful where you store them and maybe soak them in some oil.

Obviously the best way to do this would be to do a lap with a recently serviced fork, have a quick and meticulous mechanic like Topher do a burnish after that lap, and then repeat with the same settings. Having a day between rides makes impressions less reliable but I have been experiencing less hand and arm fatigue and my confidence on the Zeb has gone up a notch as well. There is unquestionably something to this procedure.

If you are interested in a Canadian-made tool to perform this task, check out Relative Motion Suspension.

Comments

Sven Luebke

4 months ago

> Recall that the adult human body is comprised of approximately 60% water, some of which is constantly leaking out of our skins mixed with oils and salts. When you touch bare steel with your hands, skin oils, sweat, and the salt contained in sweat stick to the steel and will cause rust. It’s only a matter of how quickly and deeply.

> The solution is to avoid touching bare steel you will later store away with bare fingers, and if you do touch the blade, wipe it clean and apply some oil from your oil pot or spray can right away before returning it to storage.

I copied the above off the internet, because it was easier than trying to tell you to not touch tool steel with bare hands, but to wear gloves. Look at the corrosion marks in the photos - fingerprints. Fuel systems 101.

Reply

fartymarty

4 months ago

Maybe 2024 will be the year that bushing burnishing becomes a thing...

I had never heard about it until about 6 months ago. I had heard Chris Porter talking about scoring bushings to create a looser fit which allowed more oil between the bush and stanction but not the specific tool.

I would argue that all reasonably level forks should have their bushings burnished in the factory as part of the QC process.

Reply

baronkanon

4 months ago

It is a manual task, where you need to check in between to verify. I have done some forks now, and all have been different in terms of alignment and amount of burnishing required. To have this in production with ramp up the cost substantially.

Ideally I agree with you, though.

Reply

Timer

4 months ago

I can't imagine that something like that can't be automated by a capable engineer given the ressources.

However, when talking about automated processes at the factory, it might be more efficient to invest in precision machining of the bushing seats in the casting itself. That could eliminate the need for burnishing in the first place.

Reply

baronkanon

4 months ago

The big anomaly is the pressing of the bushings, where they get deformed in a non-deterministic way, I guess. The sometimes get ovalized, so the burnishing will force them back to circular form

Reply

Timer

4 months ago

Good point. I didn't think of the pressing process potentially introducing distortion.

Reply

GrundleJ

4 months ago

assuming the bushing and it's structural base material are weaker/less ridged than the fork lower, I would think that the pilot they are pressed into would determine the final shape and roundness.

Reply

Justin White

4 months ago

As mentioned in other comments, chassis alignment is super important too. Anyone considering burnishing should try the gravity test both with and without the wheel installed. If the fork doesn't have a floating axle system, there is a good chance that it will pass with no wheel but "fail" with a wheel. And even after burnishing, it will likely continue to "fail" with the wheel installed.

So the factory would need to be doing that QC with a proper hub width that has a tight tolerance, and you would need to be using a hub with the same dimension and tight tolerance to really benefit from that extra expense.

Reply

Mammal

4 months ago

I've had two forks burnished over the last couple of years, both with amazing results.

1) I bought a barely used DVO Onyx, knowing that the brand had a high percentage of forks with tight bushings. After one chat with the seller, I knew that was likely the issue, and got it for a total steal. Took just the lowers and axle down to SuspensionWerks where my buddy could do his burnish thing, and $20 later, it was buttery smooth. Unparalleled value.

2) I had my Dorado burnished at the same place, different buddy of mine performing the service. In fact, it sounded like it was so much work, they had to take turns back and forth until it was done. I also had a small damper mod done at the same time, so the bushing improvement isn't in isolation, but that fork moves like nothing else I've experienced. Simply amazing through rough stuff.

One note about the now-looser fit after burnishing - lubrication fluid takes up some of that space between stanchion and bushing when the fork is properly lubricated. If you have your bushings burnished, make sure to keep your lowers well lubed. Using thicker oil also tends to help keep the noticeable slop to a minimum (I use Fox Gold in my DVO Onyx).

Reply

SilentG

4 months ago

Asking for a friend, what was the Dorado damper mod?

Reply

Mammal

4 months ago

Ported Pistons for increased rebound circulation flow, and roughed up the piston surface. A couple of mods my buddy developed when supporting Eddy Masters/Bergamont Team. If you want his contact you can shoot me a PM, he still services Manitou stuff as a side gig.

Reply

SilentG

4 months ago

Origato!

Reply

Justin White

4 months ago

"I'm sure five minutes with a Scotchbrite pad will clean these up as good as new"

5 minutes with a Scotchbrite pad can take off a good chunk of microns, so I wouldn't want to be cleaning them up very often, lest you polish the needed oversizeness right away eventually. Much much much better to keep them as dry clean and dry as possible, perhaps wrapped in a lightly oiled cloth.

Reply

Mammal

4 months ago

I was going to say the same.

1) It's terrible to leave precision steel unoiled in a damp environment like that.

2) Removing the oxidization with crude methods negates the precision of the tool.

Reply

T-mack

4 months ago

Treat them like gauge blocks and store them lightly oiled at all times. Problem solved.

Reply

Cam McRae

4 months ago

I believe I said that! Excellent suggestions otherwise. ;)

Reply

Andy Eunson

4 months ago

The bigger point here is that a new fork that costs $1500 or more should not need burnishing or as with my last fork new bushings because it had an audible knock. I’ve had loose bushing more than once and I would guess maybe bushing that required a burnish but didn’t notice or figured they’d break in with use.

Reply

Tadpoledancer

4 months ago

kjhg? Covfefe?

Reply

fartymarty

4 months ago

asdf placeholder???

Reply

Justin White

4 months ago

Perhaps it was to prepare you for the strnage quote in the next paragraph. I've read it a few times, some punctuation seems to be missing, it doesn't quite make sense as is.

Reply

Cam McRae

4 months ago

I have been trying to re-read that quote without understanding it and I’m unable to. Unless you are taking about a different quote?

Reply

Justin White

4 months ago

"The cross-country riders could be more sensitive to it than DH, especially locked out, but downhillers, when the fork was loaded, they'd be so far into the overlap of the bushings, they normally wouldn't feel it unless they were unweighted and pulling over something flat."

Why would XC riders be more sensitive? Wouldn't "especially locked out" mean the bushing friction has almost no impact?

Why is the fork only heavily loaded when the overlap is greater? And what does overlap have to do with the bushing tolerances? If a bushing is tight, it's not going to suddenly be looser when the overlap is greater.

Downhillers normally don't feel it? But there was a lot of mention this kind of thing basically starting with downhillers...

(There is also at least one new comma that wasn't there initially.)

Reply

mrbrett

4 months ago

I think that quote is in reference to bushing slop, not friction. Or at least that's how I read it. Rattly, locked out XC forks ...

Reply

Justin White

4 months ago

Ok, that makes sense now.

Cam McRae

4 months ago

Nailed it.

Cam McRae

4 months ago

I must have sneezed editing!

(Just a placeholder I forgot to delete)

Reply

SilentG

4 months ago

I had seen (read?) people raving about burnishing on MTBR. At some point I picked up a Mezzer from someone who had burnished the bushings and I did some testing against my stock Mezzer.

Big difference which really surprised me but it does make sense and I think Ohlins does something with bushings on the RFX forks as a design thing.

It is hard to quantify the difference in feel - smoother action and a more liquid/free feel I guess is how I would describe it.

I picked up a tool from NaturalTalent on PB which is made in Canada and have been burnishing all of my forks.

I'm not sure where RMS is located but the tools look very similar so maybe NaturalTalent is RMS or makes them for RMS. Blueliquidlabs is another source in the US for the tool and dies (along with Fox and Ohlins but those are crazy expensive - close to $1,000).

It isn't hard to do as a technique (1 beer job) and I'm not trying to find the margins by putting larger and larger dies through the bushings so I'm not worried about premature stanchion wear or bushing knocking or any other scary things that go bump in the night.

What has been interesting is that some forks are pretty good as far as the bushings being nice and round and others have been an absolute chore to get through the first time including forks where one side is decent but the other side is a real bear.

Reply

moraucf

4 months ago

Eyyy I sold you that mezzer haha. Glad you ended up enjoying it.

But yeah I'm still a huge fan/advocate for burnishing.

Reply

SilentG

4 months ago

Small world!

Reply

Kapolczer

4 months ago

I believe that RMS is the suspension tooling business that NaturalTalent on PB owns/runs.

Reply

baronkanon

4 months ago

It is, I asked him and got it confirmed.

Reply

Brad Nyenhuis

3 months, 2 weeks ago

I too used the NT Burnishing tool on my Mezzer Pro. Then my wife's Mezzer Pro. Then a customer's new Mezzer Pro (Yeah, I'm a big fan, of both the Mezzer and burnishing).

My buddy, who actually bought the tool I borrowed, made a video of the gravity drop difference:

Mezzer Pro Burnishing

Reply

the prophet

4 months ago

After a few years of working solely on suspension, I have learned that the bushings are usually not the cause of a sticky fork.

Chassis alignment is a much bigger issue than the bushing fit. In 75% of forks that need work, it is the alignment between stanchions and lowers that is the problem.

Once the seals are removed and the lowers are clean and dry, drop each stanchion in individually to check the bushing fit. They should drop to the bottom with close to zero friction. That is the bushing/stanchion fit.

Now bolt your front wheel in the lowers and drop the stanchions in together. If it is now tight and the CSU will not drop to the bottom on it's own, you have a chassis alignment issue.

It is all too common for shops to go crazy on the bushings when in fact it's that chassis that is the main problem. In my experience, very few of even suspension only shops are dealing with this correctly. Fluid Focus is one that does it right;

https://www.instagram.com/p/C0h09OCvxnf/

Reply

Justin White

4 months ago

So you're saying that having a fork with an intelligently-designed floating axle system, like Fox's or Manitou's (anyone else?), is often much more important than performing this operation?

Reply

Shinook

4 months ago

Ohlins does also, at least on both the RXF36 m.2s I've had

Reply

Moritz Haager

4 months ago

Is there a way to address chassis alignment? Can you add a floating axle to say a Lyrik?

Reply

Justin White

4 months ago

Not really, the dropout would need a pinch-bolt. Best you could do is get some disc shim stock to add width to the hub, or precision grinding of the endcaps to reduce hub width, to match the chassis alignment.

Reply

baronkanon

4 months ago

I have bought a tool to sand some off the dropouts from a user on MTBR. It works very well as well.

Reply

baronkanon

4 months ago

Nope. Floating axle is a system implementation. One can use a tool to find the perfect spacing for low friction and then work on the hub or dropout to make them aligned.

Reply

cyclotoine

3 months, 4 weeks ago

Here’s a genuine question I am asking myself. If the alignment is slightly off and burnishing the bushings is enough to compensate for that bad alignment and the riders notice improved performance isn’t it worthwhile anyway despite the cause and effect being misaligned?

Reply

Justin White

3 months, 4 weeks ago

If the bushings get loose enough to feel good despite the misalignment, there might also be enough looseness at one end of the alignment to be noticable/annoying, so that's the trade-off to compare for "worthwhile".

Reply

Andeh

4 months ago

Burnishing can make a huge difference. When I had an EXT fork, the last 1/3 of travel was unusable. I sent it in to them and they checked the bushings (which were supposedly done at the factory) and found that the left lower one was very tight. After that I could get full travel if I ran low enough pressure. Similar story on 1 of the 2 Zebs I have (one came to me already burnished by Diaz, the other was brand new) - burnishing gave me about 10-15mm more usable travel.

The great thing is aside from the tool being a bit pricey, it's simple enough that any fork service shop should be able to do it, and it can be done alongside a basic lower service.

Reply

David Staley

4 months ago

I figured I would chime in because I'm still desprately waiting for snow and I can't bike where I'm at right now.

So I ended up picking up one of the RMS tools after hearing about them. Justifying my purchase with the fact that no one around me was even offering it, and between myself, my wife, and various friends forks I end up servicing it would justify its purchase. And yes, that is totally the reason, and not the fact I like shiny well built bike tools...

So I figured I'd give a short rundown of my experience with it across multiple forks.

180 Fox 38 with a Vorsprung Seccus

So, this fork was interesting because the damper side was not nearly as tight as the air spring side, and when I did the gravity test before burnishing, the fork would kinda "waddle" down due to the friction difference between both sides. After burnishing, the fork didn't feel all that different off the top (probably due to the Seccus) but the midstroke felt a bit more free. I also noticed that when the air was let out it was easier to bottom out than before, feeling like it got hung up less on the last 15% of its travel. Did that ever come up in a riding situation? Hell no, a 180 Fox 38 w/ a seccus is a beast of a fork and I ended up fiddling with it pretty much every ride, but don't think I found anything more than 167 MM of travel on that thing. I could do a whole other review on that fork.

160 Fox 36

This is my wife's fork on her "big bike" and after burnishing it became immediately clear this was a change for the better. She's a lighter rider and ends up having a large portion of the damping force made up of just system friction, so a reduction in that paid dividend. With the same settings as before it was burnished, she ended up using about 10mm more travel per ride and she noticed a reduction in arm pump. We actually ended up putting a couple more PSI in the fork, which is pretty sweet.

120 Fox 34

I liked this fork before burnishing, but after burnishing, holy smokes. The two 34's I did this to were both much much tighter than the previous forks I did, and gave me a pretty solid work out in the process. The new found performance was nothing short of spectacular, and made the whole experience and purchase worth it. I personally was able to completely change my fork from 10% sag, less volume spacers, and slower rebound to 18% sag, a couple more volume spacers, and a much much faster rebound. allowing for me to control the fork ride height via the rebound. Not only did the fork track so much better, but it also allowed me to ride like a complete dickhead on my spur. The fork felt like it was quicker to respond since it didn't have to muck with as much static friction before moving.

In terms of what the forks are now like to deal with, there's a slight bit of "wiggle" or something on my 38, but only at the very top of its travel and when I apply the front brake in the garage (its probably the pads wiggling in the caliper). They do seem a touch more sensitive to oil pooling in the lowers so flipping them upside-down before a ride is helpful, and they do have more of a noticeable improvement after servicing (which means that they benefit from being more proactive on the service intervals).

In short, I would recommend burnishing your fork, and if you like well built tools and want to be "that guy" the RMS tool is great.

Reply

Cam McRae

4 months ago

Thanks for the detailed contribution David! Very well expressed as well.

Reply

David Staley

4 months ago

Thanks! I've been a long time lurker and figured it was finally worth giving my 2 cents on something!

Reply

Justin White

4 months ago

If you think the pads might be wiggling, just pull the brake harder, they'll lock down more than enough to determine if anything else is wiggly.

Did you try the gravity test on the 38 one leg at a time? Waddling down makes me think the upper legs could be splayed out, or the lowers canted in. Could also explain the minimal change of the top (where the width lines up) and more change at the middle and bottom (where the width differential is greater and greater bushing clearance makes up for it more).

Reply

Tjaard Breeuwer

3 months, 3 weeks ago

Ha, David, Icould just straight up copy and paste that first paragraph! Unfortunately including the no snow for skiing part.

Reply

finbarr

4 months ago

Are there any shops in the sea to sky area that do this?

Reply

Mammal

4 months ago

Suspension Werx

Reply

danithemechanic

4 months ago

Even as a bike mechanic it took me a while to figure out what "burnishing bushings" meant, since there was simply no knowledge floating freely on the internet.

It took me a few IG posts to understand it, but i wish i could read this article instead.

I didn't bother asking my suspension colleagues since i consider that a whole different job than mine, with a whole different (pricey) workshop to go with it.

Cam i wish you included the tool retail in the article, wich is 350€ for the whole set, wich i don't recommend the diy mechanic should get even if fucking with your fork seems cooler than giving that damn bike of yours one more wash.

Reply

baronkanon

4 months ago

There is a full thread on this on MTBR. I bought a tool last year, and the difference on my forks is awesome!

Reply

fartymarty

4 months ago

It would be cheap split between a few riding buddies.... I guess the downside is that it's a one off operation until you get a new fork.

Reply

Timer

4 months ago

Most suspension tuners and even some service shops offer burnishing of bushings. For the invidual, that is probably the much cheaper option when added to a regular service.

Reply

Cam McRae

4 months ago

Good point!

The whole set is indeed pricy, and certainly not what I would recommend for a home mechanic.

Reply

AndrewR

4 months ago

And most home mechanics are not going to need the entire set. We tend to be tribal so stick to one brand. For example I would 'need' a 35 mm (for the Arrival 130 with a Lyrik), a 38 mm (for the Arrival 170 with a Zeb) and a 34 mm (Mastadon Pro on the fat bike- an outlier but the Bluto is not great in the cold which is kind of weird for a fat bike fork).

So $300 and I can have all my bikes running like silk for ever. But ideally this is the kind of thing that my local suspension service centre would have so that they can make my forks run like silk for ever.

Reply

danithemechanic

4 months ago

Being a one time operation i think it'll be cheaper to do it at the shop.

Also, as with every suspension tool if buy only the one for your current suspension, the day you get a new fork you're assured you'll have both the bigger and the smaller sizes than the one you need.

Reply

ohio

4 months ago

It is def cheaper at a shop ($40USD quoted to me) but remember to send in only your lowers. I mailed in a whole fork (bc I thought the stanchions needed to be measured for proper sizing), and ended up with a $300USD tab by the time they were done with their lower service that included fresh oil and seals. AND once we were in there I had them revalve it too (that one's on me). Shop did good work and I love the fork, but in retrospect, I should have just bought the tool.

Reply

baronkanon

4 months ago

I do this tasks for friends, and I require both uppers and lowers to be sent as the uppers are not properly aligned, so the sizing is dependent on both uppers and lowers to do the job properly. If you strip the fork and only ship the lowers and uppers, no air spring, damper or seals. Doing it with the wipers installed gives too much resistance and masks some of the feeling for the result.

Reply

baronkanon

4 months ago

Also check out Bitul from Poland, who have a well priced kit.

If you think Fox or Öhlins are expensive, then check out Laba 7, who also makes dynos and vacuum fillers...

I reached out to naturaltalent if he is RMS. Based on his updated images on Pinkbike Buy and Sell, it seems he is RMS. just need to get it confirmed.

Reply

Shinook

4 months ago

I've gotten mixed responses on this when I ask suspension shops about burnishing bushings. Most shops I ask say that the majority of forks do not require it and that the bike shops burnishing bushings are largely screwing up the forks they work on, others said it is hit or miss depending on the brand. My understanding is also that if they are too loose, they can bind, as well, and IIRC some early Fox 36s had this problem with bushings would prematurely wear.

Part of me wonders if the benefit most people feel from doing it has more to do with ensuring proper lubrication of wiper seals, oil volume, and the things that come with properly serviced lowers instead of the burnishing itself. Basically every fork I've had except for my Mezzers and Ohlins came with none of that correct from the factory. That said, my last Zeb had an astounding amount of friction when seals were removed between lowers and stanchions, so maybe not.

Reply

Mammal

4 months ago

Lack of lubrication can cause issues for sure, and the two issues can be confused, for sure. But they are in fact, two different issues. As mentioned in the article, you can often tell when fork bushings could use burnishing just by removing the lowers and feeling how the stanchions slide within the bushings (with everything lubed well). It can be a night and day difference.

The two brands you mentioned are interesting. The first Mezzers had a big issue with bushing slop from the factory, so that was the opposite issue. They dialed that in after the first production run of the lower casting, but it's possible they still run a looser fit than some brands. I know for a fact that Ohlins runs a looser fit than most brands, just by design. Apparently the burnishing tools for Ohlins are slightly oversized compared to those for other brands with the same diameter stanchions.

Reply

Justin White

4 months ago

SRAM/RockShox seems to make some decisions* for suspension based on in-shop/parking-lot feel, so it wouldn't surprise me at all if they generally had the tightest bushings around to avoid any slop/knock that might be felt in the "grab the front brake and rock the fork" "test". This completely ignores the fact that the bushings are hydrodynamic and actually float the stanchion in the oil when in motion, and should have a little "slop" when static. But perhaps reduces questions from uninformed customers. So, trading off actual performance to avoid needing to educate both buyers and sellers... lose-win? Or lose-lose?

*(Remember the C1 air-spring "upgrade" to "fix" pneumatic top-out "stealing travel"? It did this by taking the negative chamber out of the equation at top-out by moving the piston to sit on the transfer dimple. Less sag with the same pressure even under bike weight alone, and greater breakaway force from top-out. I hated it on my Pike: the spiky damper, tight bushings, and stiff spring after unweighting were way worse than "missing" a couple mm of travel when the bike was sitting static.)

Reply

GB

4 months ago

What about a spring loaded honing tool if bushings are deformed from pressing or too tight ? Guaranteed to be perfectly round after honing.

Shame a piece of equipment that sells for 1500$ or more is not properly QC,d to check for tolerance.

Reply

mrbrett

4 months ago

So, from the people that have done/had this done, is it fair to say I could assess my fork whilst completing a lower leg service?

i.e. Put each stanchion through a lower leg independently to see how freely (or not) the fork glides? Logically - if it's smooth, I am good - if it's sticky, I would benefit from a service like this? Is that an oversimplification?

Reply

Justin White

4 months ago

It's not a perfect test, since the bushings are hydrodynamic bearings so without proper lubrication and appropriate movement they don't actually do their best job of dynamically keeping the stanchions from actually touching the bushings. But, if the friction is obviously quite high, and you're ok with possibly feeling a little knock when rocking the fork at top-out (because, again, those bearings aren't really doing their job without the appropriate sliding movement happening), go for it. Worst case is your stanchions are relatively undersized, burnishing introduces a lot of slop, and you end up needing new bushings (but maybe they're a better size!)

Reply

Justin White

4 months ago

Doesn't this "one over-size fits all" approach assume that the stanchions have much tighter tolerances than the lowers & bushings? With some fork service packages, you can request a stanchion to bushing tolerance check and new bushings installed to best match the stanchions (perhaps this is just burnishing behind the scenes?). In that light, wouldn't it make sense to have a couple few tools for each leg size with different oversize amounts? Perhaps start with a 25 or 50 micron, try a 75 or 100 micron if the first is not enough, maybe 125 or 150 micron for extra tight lowers/bushings?

Reply

Timer

4 months ago

I'd think that assumption is correct. Stanchions are just tubes of uniform thickness which can be made en masse to very precise tolerances. Lowers are cast and then pressed together with the bushings. Both processes are much harder to do to precise tolerances.

I'd be more worried about alignment, both on the side of the crown and the casting side.

Reply

Justin White

4 months ago

Lowers are cast, but then machined to tolerance at the bushing seats, so I'd blame the pressing and tolerance of the bushing itself before the lowers. Any yeah, alignment is quite important.

I was disappointed when the Fox 36 lost the floating axle (and the 20mm! but that's another can of worms) for most OEM applications for a few model-years, especially as wheel size, and thus fork leg length, was going up which meant hub width tolerances were getting even more important. At least now the floater is back as standard on 36s and 38s, even for "QR" axles, but upgrading an older fork is not really cost effective as replacement lowers alone cost a good chunk of the price of a whole new fork.

Reply

Cam McRae

4 months ago

An interesting alignment element that Fitz (quoted above) shared with me, and that hadn’t occurred to me, is that inverted forks don’t have this issue. It makes much more sense, for this issue at least, to clamp stanchions to your axle because they move independently. I haven’t ridden one since the heyday of the Dorado.

Reply

Justin White

4 months ago

Why wouldn't inverted forks have this issue? They still have a fixed chassis width, and without a floating axle the dropouts will be clamped tight to whatever the hub width is. If those widths aren't the same, the lower legs won't be parallel to the upper legs.

Reply

Cam McRae

4 months ago

Floating axle still required. Here’s what Fitzy said;

“Justin is correct. Meaning if the inverted fork axle isn’t floating, the alignment issue would be the same. The difference is, without a stiffening brace on inverted forks, the sliding tubes are dependent on the floating axle and crown for their alignment. It removes an additional misalignment variable.”

Allan Maxwell

4 months ago

I'm old and my memory may be inaccurate, but I believe this used to be something the suspension tuners did when they rebuilt your forks. I specifically remember Push Industries offer of "sizing" the bushings. At the time, I took that to mean they replaced your current bushings with ones that better fit with your sliders and that slider manufacturing tolerances must be wide enough for different size bushings to matter.

Perhaps they were always just burnishing them?

Reply

jdt

4 months ago

Perhaps a new upcharge service at Fluid Function?

Reply

Brian Tuulos

3 months, 4 weeks ago

If you think ball Burnishing your bushings is an upgrade, just imagine how needle roller bearings on a Cannondale lefty performed. I’ve ridden many forks and to this day my 140mm coil sprung lefty max was jaw dropping responsive. It’s too bad Cannondale didn’t market it correctly to the masses and had shitty dampers. Reading this article makes me think of it.

Reply

Tjaard Breeuwer

3 months, 3 weeks ago

Yeah, I had a Prohet with that fork. Certainly, in concept it was a great idea.

Reply

Please log in to leave a comment.