Editorial

Old Tools and the Evolution of the Bicycle

If they were anywhere, they were in my old Rubbermaid toolbox.

Despite rarely cracking it open, I've kept my old tool storage box as any good (but semi-functional) hoarder should. Sifting through the stack of obsolete steel implements, reproducing the sound of shopping carts mating, I eventually found every 1980s era bike tool I needed.

What this 25 year old toolbox lacks in charm (who gets misty about plastic?) it has made up for with longevity and durability.

An aging family friend came down with a case of Marie Kondo recently and decided two 10-speed bikes, a Norco and an Apollo, had to go. Knowing I was a 'bike guy' he asked if I could use them. Obviously! I just had to figure out how. Eventually I decided my kids could ride them to navigate the neighbourhood with newfound freedom.

Sadly my teenagers' interest in the dusty jalopies paralleled Don Cherry's fondness for cricket. So they sat, gathering even more dust, until my sister-in-law asked me about riding to work on a truly worn out old mountain bike her husband had abandoned. Terrified of that ghastly job, I steered her toward the Norco and surveyed the damage wrought by years of neglect.

Every time I use something I have saved for years, it reinforces my compulsion to hoard old bike tools and parts. This project was a big setback in my efforts to declutter.

It was difficult to turn the cranks by hand and I was certain the low quality grease had turned to glue. The headset was notchy, the cables rusty, and the hubs were over-tightened. When I worked in shops, bikes like these were a huge part of our business. Mountain bikes were beginning to take off but unless you spent a lot of money, and I mean $400 and up, they were heavy enough to have steered Lance toward golf. And the parts were generally pressed steel crap.

We used to assuage our guilt for selling this piece of shit Raleigh Portage by saying; "at least it's not from a department store." Meaning they were built and checked over relatively well, but really that was just putting icing sugar on said slice of caca.

I'm not proud of having worked in a shop that sold the unfortunately named Raleigh Portage (you weren't carrying that anchor anywhere). It was made of pipe rather than tubes and the easily dented steel wheels and crappy tires weighed 9 lbs apiece. The brakes may have been noisy, but that was the only evidence of them being applied. All this for 199 CAD. A Norco Monterey, with aluminum rims, derailleurs that worked, and upright bars swapped in for a small fee, was an easy upsell for people who were never going off road. And talking someone out of a Portage meant I didn't have to perform the impossible task of making it rideable before it left the building.

My favourite pieces in the workshop belonged to my grandfather who was a plumbing contractor. This is a great place for the small parts I have accumulated over the years and regularly needed bits like cable ends, pedal pins, and rotor bolts.

Most of my bike shop time was in the prehistoric era before even front suspension was common and the revolution in stopping was cantilevers, so I knew my way around this simple Norco very well. The original build was a done poorly; bearings weren't adjusted and the fenders were improperly installed. I knew the shop* was to blame because it was clear the Monterey hadn't travelled more than 10 miles in almost 40 years.

*no sticker identifying the shop could be seen and I understand why

I dug cone wrenches out from a cabinet I use more regularly, and got busy bringing this under-appreciated machine back to life. I almost needed a chisel to remove the old grease from the bottom bracket but once I thoroughly scoured it, reassembled it with fresh grease, and adjusted it just to the point where there was no play, it spun effortlesly. It wasn't Campagnolo-smooth but it should improve over time. Once adjusted properly, the headset and hubs spun similarly so I decided against repacking them (let's see how much my wife's sibling actually rides before going too deep). I replaced the derailleur cables, lubed the brake cables and gave the drivetrain a good degrease and lube. Etcetera. Finally I gave the geriatric Norco a bit of a spit and polish and she looked very nice indeed.

I don't miss many of the tools that no longer need to hang above the bench.

The trickiest job was the bottom bracket. Handling the lockring and pin tools at the same time with neither slipping off, is tricky on its own. Having to worry about folding back the metal supporting the shoddy steel slots on the lockring or stripping the pins on the cup is an added bonus. And that got me thinking about modern bikes and how they well they mesh with the tools we use to assemble and maintain them.

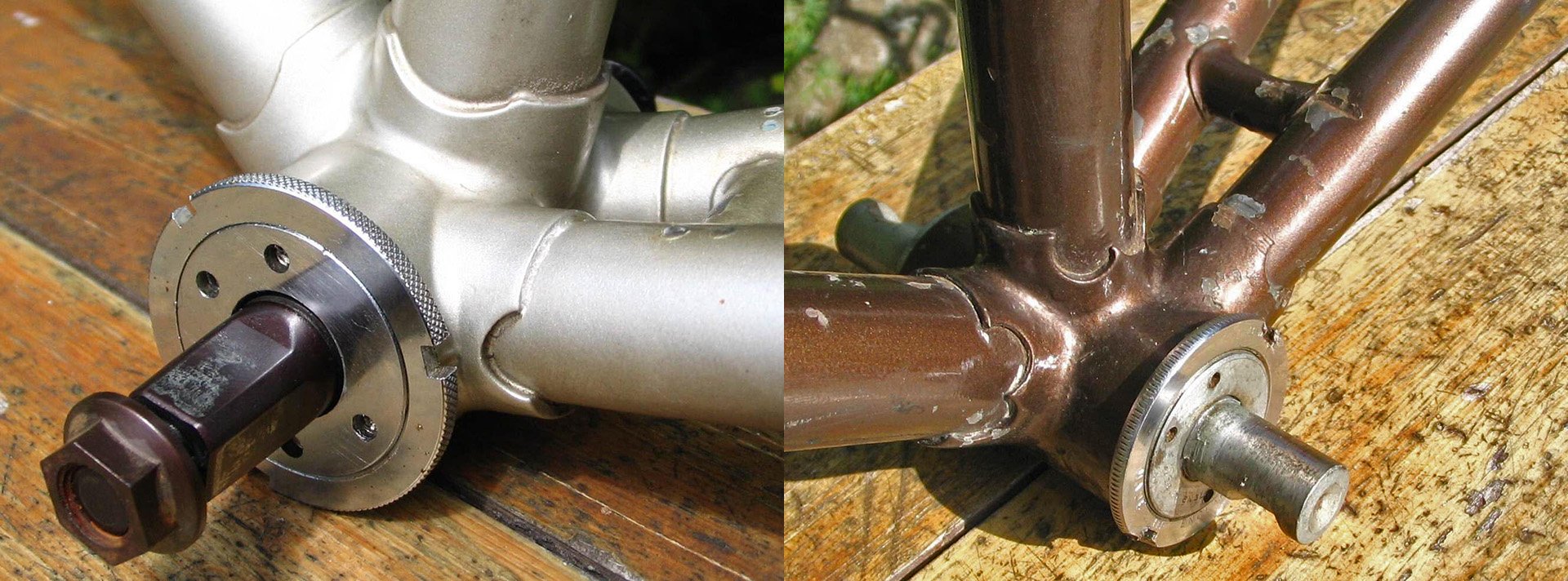

These are actually much better quality BBs than the one found on the Norco, but a close look shows that the slots on the brown bike's lockring are almost destroyed.

The last bike I built didn't require a headset press because the bearings just dropped into the top and bottom integrated cups. Press fit bottom brackets aren't well-loved but with a press of some sort* they are a breeze to install or remove. Even the nicest bikes from just a 10 years ago might have needed threads chased, bearing surfaces and disc tabs faced and possibly even a good reaming of the seat tube and head tube. The 2015 Giant Reign I owned wouldn't work with a set of Magura brakes I was trying to test because the tabs weren't sufficiently precise. I'm certain that would no longer be an issue; manufacturing has taken some big leaps in recent years. Precision now reigns.

*my example is a fancy press but you could use adjustable wood clamps or even a mallet in a pinch if you are careful – but don't quote me...

My sister-in-law's new commuter has already been put into service. The high rise bars are a little strange and the drop bar levers were never swapped out, but otherwise the Norco Monterey is entirely serviceable as a hipster conveyance. Photo - Federica Piccone

Many elements of modern mountain bikes are a massive pain in the ass of course. Tubeless tires are at the top of the list and keeping suspension, droppers, and brakes in fine working order can be challenging and time consuming. Not to mention the messy fluids each of those jobs can involve and the extra complication caused by internal routing. But parts are made so much more accurately, that there are many areas that now require little thought. Headsets were often a nightmare in the past, regularly coming loose mid-ride, and ovalized head tubes, which doomed your frame to the glue factory, were common. Chains rarely break (in my experience) these days and the failure rate for derailleurs and hangers has plummeted as well.

She has taken to the experience with enthusiasm, even making "fair weather panniers." Photo - Federica Piccone

The best part for me though is ditching finicky tools and adjustments. Cup and cone bottom brackets require four or five tools for installation or removal and even the best sealed poorly. Headsets had to be pressed firmly into steel or aluminum, were tricky to adjust and required two large tools that were tricky to carry in a jersey pocket. Adjusting one now likely requires two Allen wrenches that you'll find on every multi-tool. Shimano still uses cups and cones in their hubs but those are relatively easily adjusted and cared for. Not as easy as the cartridge bearings found on most new bikes though, until the bearings need swapping out that is. Nuts and bolts used to hold bikes together but I rarely need my set of metric wrenches any longer.* There was a time when today's pocket tools would have been useless in many situations, but now even a compact one will do most everything you'll need on the trail.

*the last time was an 8mm box end for the compression nut on a set of Hayes Dominion brake levers

I'm not saying bikes are less complex these days, or easier to work on overall. I'm saying there is less day to day work and it's generally easy to perform. Of course once we start talking about wireless dropper posts and electronic valving, all bets are off.

(One thing I lament is the lack of consensus on fastener heads. It seems to me that much of the bike, and certainly the entire cockpit and headset, could be handled with T-10 and T-25 Torx head fittings. For me Torx are easier to use, less likely to strip, and I've never had a Torx tool become noticeably worn, a regular issue for Allen head tools. Hex heads make sense for 6mm and above, but for everything else can we just use Torx please?)

It's easy to lose sight of how far bikes have come mechanically over the din of (often well justified) complaints about new standards. Modern mountain bikes, even at the low end, are marvels of elegance and strength and most everything that needs to be done can be completed by ham-fisted home mechanics like me, with inexpensive and common tools.

Niggly bits aside, a little perspective made me very glad to be working on and riding bikes in what is in many ways a golden age

Comments

Sven Luebke

4 years, 7 months ago

* a two by four hammer gently tapping works just as well

Reply

fartymarty

4 years, 7 months ago

I'll second that.

Reply

Mammal

4 years, 7 months ago

Yep, hammer and block-o-wood is my method of choice*.

*Precision taps may be required.

Reply

Vik Banerjee

4 years, 7 months ago

"Of course once we start talking about wireless dropper posts and electronic valving, all bets are off."

By the time that talk has started I've already clicked on another link and moved on. ;)

I was at a big bike shop recently with a bling demo bike the salesperson repeatedly wanted me to try out. I kept saying no. He just couldn't fathom that I had no interest in wireless shifting or wireless droppers. I kept replying that the number of times I wished my shifting or dropper was wireless was exactly zero and I certainly wasn't paying extra for the privilege. He looked at me like I was riding a pennyfarthing We had to just agree to disagree. :)

Reply

Cr4w

4 years, 7 months ago

Don Cherry's fondness for cricket. +1. Wait Is that because he only has eyes for hockey or because cricket Is played largely by those people? Either way +1.

Reply

JVP

4 years, 7 months ago

We need to pool together and buy Cam some Knipex pliers and go disappear that complete set of crescent wrenches. The horror.

Reply

Cam McRae

4 years, 7 months ago

I would love some of those, but I like my boxends as well. Reminds me of the bad old days.

Reply

kekoa

4 years, 7 months ago

For the longest time a riding buddy used to carry two full length, 1.25" park headset wrenches for his Answer Manlytool FS because the Chris King headset wouldn't tighten correctly. Modern stuff works better.

Reply

Andy Eunson

4 years, 7 months ago

You are out of anCnoc. I am too.

Reply

Cam McRae

4 years, 7 months ago

So sad!

Reply

cyclotoine

4 years, 7 months ago

Hozan chain pliers. Nice.

I learned by ham fisting old bikes. However, with the right tools (Hozan lock ring pliers for example) any crapy old headset or bottom bracket can be adjusted without marring. Though I do agree tool interfacing has improved it's not always the case. I've seen super shallow notches on bottom brackets cups all chewed up and how many threaded bottom bracket tool standards do we need anyway? Each requiring its own precision-machined aluminum and anodized super expensive tool. It's infuriating. Every time I buy a new bike there are at least a couple of new tools I need to buy.

Anyway, great read. I thoroughly enjoyed it. And nothing spins smoother than a record hub adjusted with a JA stein hub vise.

Reply

Cam McRae

4 years, 7 months ago

Excellent points! I miss using that Hozan chain tool! Nothing works better. And I would love it if Campy made cup and cone hubs and bottom brackets for mountain bikes. Entirely impractical but they would be so sweet!

I guess that means I should break open those XTR hubs for the first time and give them a rebuild.

Reply

Alex D

4 years, 7 months ago

For press-fit bottom brackets, this is your huckleberry: Amazon

Pressing is easy and it has the drifts for that. More importantly, it removes bearings just as easily. None of that pounding crap. My local shop didn't have one when I let them borrow mine; now they do.

Reply

Cam McRae

4 years, 7 months ago

That looks pretty cool. Doesn't ship to Canada unfortunately.

Reply

Alex D

4 years, 7 months ago

I bought mine from AliExpress, if that's any better. It's essentially the same as this Enduro unit you reviewed 18 months ago--

https://nsmb.com/articles/searching-30mm-bb92-solution/

Just $40 instead of $200 and more compatible.

Reply

cyclotoine

4 years, 7 months ago

looks cool. I have the Park through axle adapter which doubles as a BB press with the right Park adapters. Being able to pull bearings would be cool though instead of hammering them with the old splayed pipe remover. I recently caved and bought the Wheels Manufacturing bearing press so I can do all my pivots like a pro. I have always been able to cobble together enough things to press in bearings with sockets and whatnot but I'm at a point in my life where time is more important, so I appreciate being able to just have the tool in front of me rather than having to improvise. Every once in awhile though I still have to use the old noggin. For example, I couldn't use the press with my Hope hubs because the bearings press onto the captive axle; Dammit, had to improvise with various pieces of the Park crown race setting tool.

Reply

Kelownakona

4 years, 7 months ago

SRAM are the real enemy when they go and pick a size like 2.5mm!!

Oh and Shimano - when you've got used to fiddling about with a T25 for your discs you then need a lockring tool but not just ANY lockring tool , one that has a large enough hollow section through it.

Reply

cyclotoine

4 years, 7 months ago

the old Park BB tool which came out before any of the socket style BB tools works just fine on centerlock rings. You don't need the fancy socket.

Reply

Velocipedestrian

4 years, 7 months ago

I recently dug out my crank puller to convert my daughters new pedal bike into a balance bike. (to ease the transition).

Had to remind myself how to set up v brakes at the same time, modern bikes are sweet.

Reply

Please log in to leave a comment.