The Hapless Wrench

Rebuilding your AXS Derailleur with Madrone

When I met Aaron Bland, founder of Madrone, and listened to him talk about his kit, I knew I was the perfect candidate. I had recently robbed a rear derailleur off a test bike because the GX AXS version on my personal bike was shifting inconsistently. Sometimes it was fine, other times it would hesitate or move two cogs for one shift, and very rarely it would drop down the cassette with an alarming cracking sound that always stopped me in my tracks. It didn't appear to be bent and I'd checked the hanger alignment and B-tension to no avail. It was just sitting there on a shelf, destined to become a donor mech. Or a doorstop.

SRAM offers a few replacement parts for their derailleurs but they don't go beyond limit screws and cage components. If you want to tangle with pivots or parallelogram links, you'll have to look elsewhere. And for now, the best place to looks seems to be Madrone.

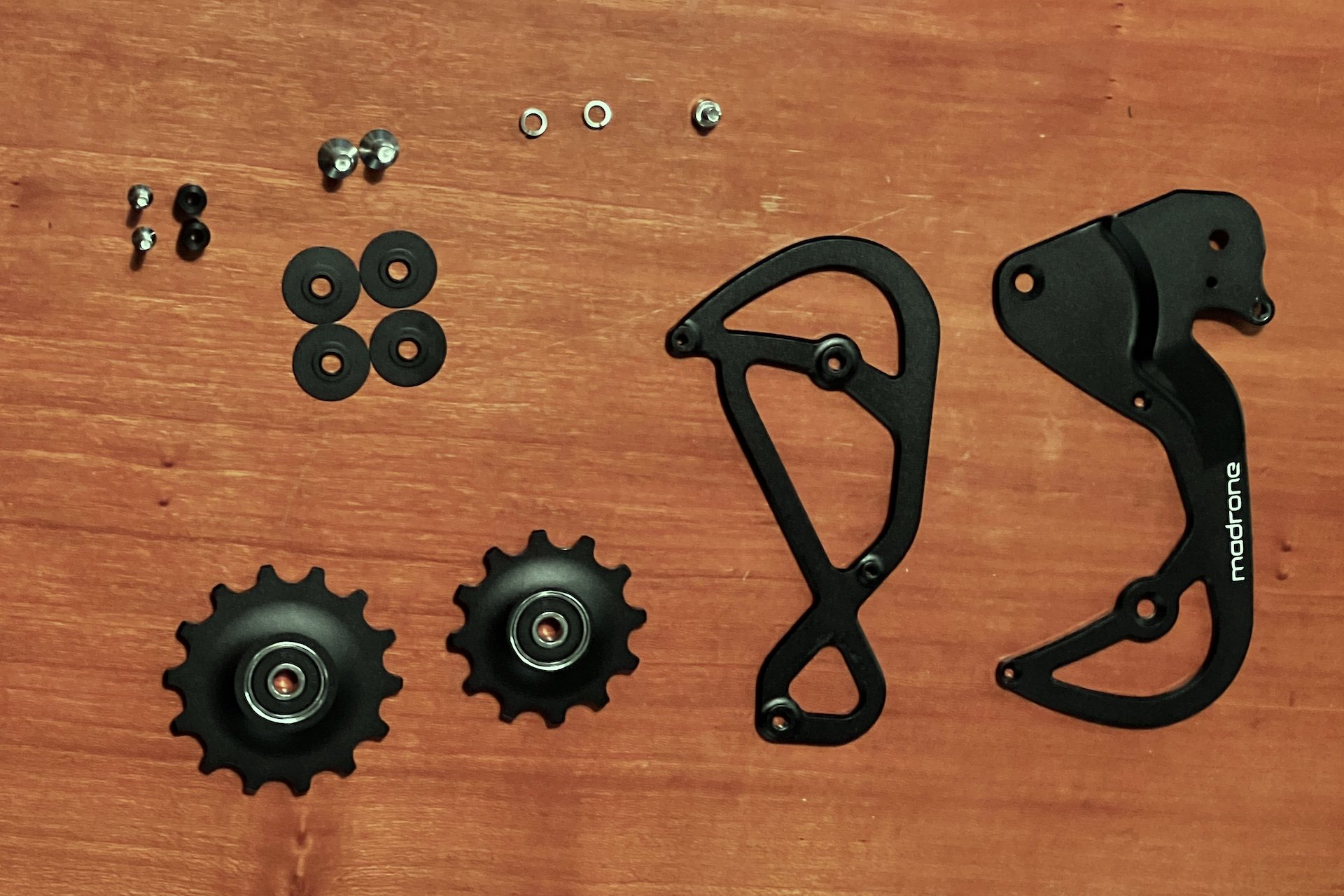

Like opening a new Lego set.

Much of Aaron's engineering background is in battery technology. He worked in tech helping Amazon with their drone fleet and for other companies, providing portable electricity solutions. You might think his entry into the bike world would have an electric edge as well but Aaron's all about mechanical for his mountain bikes.

Aaron, and his company Madrone, manufacture kits and tools to replace 8 bushings, 3 pins, 2 links, 4 shims, 3 washers and 3 snap rings needed to rebuild your parallelogram.* Madrone also makes a replacement cage and jockey wheels, and he sent me both sets of parts.

*give or take

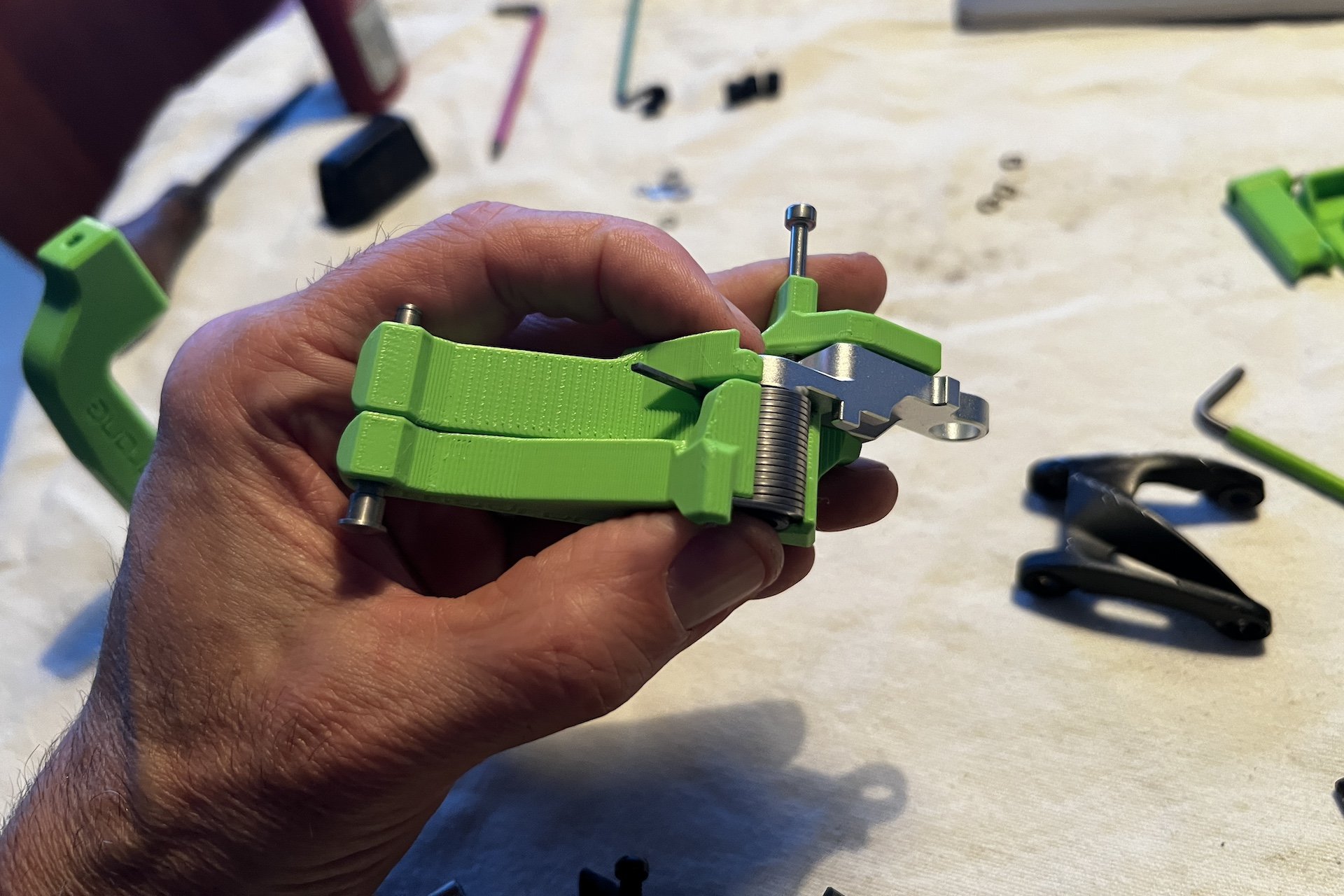

The tools, and the incorporation of parts from the finished product as tools, are highlights of this kit.

Also included in Madrone's kit are all the tools required to do the job. It's really a very complete kit but you'll also need some basic tools like hex keys, a hammer and needlenose pliers (a good set) but also a 5/32 punch, which you may not have lying around. I prefer to buy local when possible but I could only find expensive complete punch sets nearby. Instead I plugged my nose and bought one on Amazon. A mechanic's pick will come in handy as well but a sharpened spoke with one end twisted into a handle will work in a pinch.

It was impossible to look at most of these tools and figure out what was going to happen before following the instructions and loading them up. And then it all makes perfect sense.

The 3D-printed tools are really the highlight of this kit and I found myself amazed at Aaron's ingenuity. The coolest one is the "Torsion spring tool," which is a clamp that helps you preload and install the return spring, but each little green doodad is worthy of admiration.

At a certain point, I realized that I had skipped a step and had to go back. Rewinding Aaron's video was critical because I could not see any conceivable way of accomplishing it on my own. I went back hoping I hadn't passed a point of no return. I eventually realized the step I’d skipped was to remove the servo. The structure around the servo is apparently sometimes sticky but that came off easily. In the video the servo itself came out very easily, but when I went to take it out, it didn’t move at all, causing me some concern. Eventually, a good yank got it done (that’s what someone said).

I was quite sure this mess would never again exist in the form of a derailleur.

As I was putting the spring back in using Madrone’s incredible tool, I chose the wrong bushing (4mm vs 5mm) and had to extract it making for another rewind. Then, while I was installing the long bolt that holds the two parts of the inner link together, I was simultaneously trying to encourage my kids, who are 18 and 21, to finally do the dishes after three days of promises, and I missed the step that included sliding the sleeve in place. As a result there was no stop while I was tightening the bolt and I threaded it well past the point its intended endpoint.

Those were mere hiccups but then things went completely sideways. I wasn't sure what my error was. Everything looked fine but the derailleur didn’t shift properly when moving to a lower gear when I hit the AXS button.

An interesting discovery was wear from the chain in the cage. I'm not sure if this was related to the struggles my derailleur was having or not.

After clicking and double clicking the AXS button several times, I noticed the mechanism would bind when the derailleur started to move further inboard. There was some damage on the plastic knuckle cover that would lift and interfere with the movement of the outer link plate as it rotates around the joint. It actually seemed that the shape of the Madrone link plate made the problem slightly worse since the cutout where the plate meets the knuckle is slightly more rounded.

*Double clicking moves the derailleur in the opposite direction than a single click - vital information when your shifter gets smashed or your coin cell dies

The gap you see at the top of the knuckle isn't supposed to be there. This was causing the derailleur to bind because it would buckle and prevent the link from advancing.

The damaged plastic was likely related to this impact. I'm not sure if I did it or my son did, or one of the many other people who have borrowed this bike.

I used Aaron’s video to remove two of the pins I had already installed, in order to free the knuckle and went to find some epoxy.* The wear on the plastic plate indicated that it had been restricting the servos for some time. It’s always good when you have to put your 390 USD derailleur into a vice and glue it together. I also took a file to Aaron’s beautifully machined links to provide a little extra insurance that this interference would not return.

*I am a big fan of Weld Bond epoxy. It is incredibly strong but what I appreciate most is that, because it needs to be mixed to harden, the two elements never dry out. There's nothing worse than reaching for your glue only to find it fossilized.

The process of rotating the cover, compromised the fit further, necessitating more epoxy and more rotating. Once all the sticky stuff was in place, I tightly wrapped the knuckle with tape and then found the right angle in the vice to apply pressure to the problematic plastic.

Five or so hours later, when JB Weld is set but not cured (which takes 15-24hrs) I retrieved the piece and began putting everything back together. I had some more disassembly to do because I need some of the already installed parts to use in the Torsion Spring Tool.

OMG! This is the cutest little snap ring tool. It even has its own little case. Works great too. If you are handy you can remove these with a couple of tiny flathead screw drivers but this is much easier.

The two pin punch tools make removing and installing pins quite simple.

An element of this kit that I find particularly ingenious is the use of parts from the finished product as components of tools on the way to line. In this case these parts were used immediately after they were needed which meant I had to undo even more of my work to get back to where I was when the problem arose. Considering it was enjoyable the first time this was no real hardship.

Once it was time to put the cage together, Aaron helpfully laid out all the tools required in his video. He went through them carefully and when he got to the lock washers, he said "at least two of these small lock washers." I looked down, and I only had one and began to panic. ”At least two?” Does that mean three would be better and I only have one?

Getting to this bolt is a little tricky and a ball end 3mm comes in handy. There are also a couple of moves with the spring and pliers that require a deft hand. My grade two teacher described my printing by telling my parents "I'm sorry to tell you this but Cameron's fine motor skills are shit."* So if I can do it, you can do it.

*She may not have expressed it so eloquently

Just like when it happened with Lego, I assumed I was the problem. Maybe the tiny washer was stuck in one of the tiny manila envelopes I’d already recycled? Where was I going to find a 4mm lock washer? Thankfully it had just slid into a seam in one of the small boxes and all was right in the world. At least for a moment.

And in fact the rest went together quite smoothly. Pre-loading the spring was a little nerve wracking, but nothing exploded. Even more impressively, in the end it looked like a derailleur.

All the pieces for the cage.

Speaking of Lego, that's a good approximation of what this task feels like. You simply follow the instructions and eventually find you have built something cool. And Aaron's video is great. It's a bit like having a young Mr. Rogers teach you something. He's very encouraging and clear and very sincere. Just like in person, it's nice to hang out with him. And the video is very easy to follow.

I am unreasonably proud of the finished product.

My favourite thing about AXS derailleurs is how easy they are to install on bikes that have challenging internal cable routing. It literally takes a few minutes and you are done. I re-checked the hanger and the B screw and got everything tickety-boo. All I had time for was a little spin around the neighbourhood but the results were encouraging. My chain and cassette are a little long in the tooth and it took a little while to dial in the shifting with the micro adjust feature but then it was very sweet indeed.

As good as new.

As it turns out, the problem with my derailleur was self inflicted (or maybe son inflicted) and the issue wasn't solved by the Madrone kit. But I wouldn't have been able to fix the problem without some means to disassemble the links to get access to the knuckle. I could have rebuilt it with the SRAM parts and likely had a similar result, although a few of the bushings in the original links were a little dodgy.*

*Another company, Leap Components, makes a kit you can use to replace the existing bushings and reuse most of the SRAM parts. They have a how to video as well.

In case you missed it, Madrone is also planning to release a mechanical derailleur that is compatible with both SRAM and Shimano shifters, cassettes and chains. And yes, those are tiny cartridge bearings. Photo - Deniz Merdano

In some ways this is a great time to be alive. The fact that a sole proprietor can put together a repair kit to rebuild a product made by a multi-national mega corporation, including building the tools and parts in a small shop, is fucking brilliant. If your SRAM derailleur, AXS or cable activated, is acting up, I can unreservedly recommend this kit in terms of execution and quality. Obviously I can't yet talk about reliability but I have no reason to doubt the longevity of these links, pins or bushings.

The AXS Link Kit with tools costs 135 USD or 110 USD without tools

The Mechanical Link Kit with tools costs 119 USD or 95 USD without tools

The Hanger Kit costs (AXS or mechanical) 79 USD or 128 USD with jockey wheels

Check out Madrone Cycles for more info.

Comments

finbarr

3 weeks, 3 days ago

This is so cool. I love that Madrone is doing this. Hopefully it’s a successful business and they’re around for many years.

Reply

Cam McRae

3 weeks, 3 days ago

Fingers crossed. Based on my contact with Aaron, he's definitely got something good going on. It will be interesting to see if the derailleur or the kits do more business.

Reply

Perry Schebel

3 weeks, 3 days ago

he just needs to do a (paul's inspired) rasta iteration to lure the retro nerds out & he'll make bank on those

Reply

Lynx .

3 weeks, 3 days ago

Cam, glad that you followed up with this, such a FANTASTIC thing IMHO, we need more of this and less throw away and buy new, almost makes me wish I used SRAM derailleurs, almost (I hate the living hell out of the ergonomics of every SRAM shift lever I've felt/used and the crap quality for their derailleurs for the prices you pay is crazy).

I do have an old GX mechanical derailleur that belonged to a friend who I finally convinced to switch to Shimano so he could buy 3 Deore cassettes for the price of one GX, I could maybe try this on, see if it improves, read, removes the horrible slop they seem to come stock with.

Reply

Cam McRae

3 weeks, 3 days ago

It would be interesting to see a Shimano rebuild or repair kit as well. The easy thing about SRAM is that the form factor seems to be about the same so one kit covers GX/XX/XO. I don’t believe that would work with Shimano but it’s been awhile since I’ve seen several Shimano derailleurs side by side.

Reply

Lynx .

3 weeks, 3 days ago

That would be cool, for sure, but I can honestly say, out the box, tare for tare, Shimano derailleurs are way better quality to SRAM. The only SRAM derailleurs I recommend is XO or XX, GX and NX are utter shite, IMHO, so much play in the bushings, it's not funny and the price of a GX cassette is beyond ludicrous, over 3 times the price of a Deore for a weight factor of I think 50g.

Reply

Niels van Kampenhout

3 weeks, 3 days ago

FWIW you can mix Shimano and Sram 12 speed derailleurs and cassettes - I use a Deore 12sp derailleur with an Eagle cassette.

I agree the mechanical GX Eagle derailleur is of disappointing quality. Upgrading the b-bolt to the X0 version helps but you can get an entire Deore derailleur for the same price as the b-bolt.

Reply

Lynx .

3 weeks, 3 days ago

But can you mix the chains, would a Shimano chain work with a SRAM derailleur? That's the important thing and where the "magic " happens, because if you just use a SRAM chain on the Shimano cassette, you loose the designed in ability of better shifting under load, AFIK.

To me that would defeat the whole purpose of going for the Deore, a GX cassette is roughly $240 USD, while a Deore is around $80 USD - you can buy an entire Deore drivetrain, Shifter, Derailleur, Cassette and chain for less than the cost of the GX cassette.

Reply

Niels van Kampenhout

3 weeks, 3 days ago

From what I understand mixing chain and derailleur isn't a problem but you generally want to match chain/cassette/chainring.

Lynx .

3 weeks, 3 days ago

Sorry, typed derailleur, meant cassette :facepalm:

Cooper Quinn

3 weeks, 3 days ago

"would a Shimano chain work with a SRAM derailleur?"

It's all generally swappable (shifters/RDs need to match though mechanical or electronic) within 12spd Shimano and SRAM Eagle.

But, Transmission RDs require flattop chains. And flattop chains aren't backwards compatible. You can run flattop chains on XSync chainrings, though. And presumably on Shimano rings, but I've never tried that.

Niels van Kampenhout

3 weeks, 3 days ago

@Cooper

"It's all generally swappable (shifters/RDs need to match though mechanical or electronic) within 12spd Shimano and SRAM Eagle."

Shimano/Sram mechanical shifters and RDs can be mixed, I use a Deore derailleur with a GX shifter.

Cooper Quinn

3 weeks, 3 days ago

Maybe "need to match" is too strong, but there's multiple pull ratios out there to be aware of, and many won't work together.

Lynx .

3 weeks, 2 days ago

You didn't mention what speed you're using Niels, but I'm guessing 12spd?

I know you can inter-swap Shimano 10 and 11 speed stuff, no worries, just if you're running an 10spd cassette with the rest of the drivetrain 11spd, you just need to limit the RD so it doesn't over-shift and if you want to run a 10spd drivetrain with 11 speed cassette, you still need the 11spd chain for good shifting.

Also know you can use a SRAM 9spd shifter with Shimano 10spd derailleur and drivetrain.

Sorry if I'm lagging on being on the newest, but I ride in all kinds of conditions and 10spd gives me enough gear range and some room to still have decent shifting with some gunk in the cassette. I also still use an FD on a couple of my bikes or dingle ring setups, so all I use is max 11-46 cassette with my 29x2.6" wheels and then 11-42 with 29x2.3-2.4".

Niels van Kampenhout

3 weeks, 2 days ago

Yes, 12 speed. Deore M6100 RD with GX Eagle shifter. A lot of people are surprised that they work together.

The original GX Eagle RD was worn out and impossible to get to shift accurately anymore. I still have it and might be able to save it with these Madrone lego pieces. But the Deore cost $50 CAD and was basically a drop-in replacement, it only required a slightly longer cable and housing.

Dogl0rd

3 weeks, 3 days ago

I don't understand why people bux AXS. I see my friends with AXS GX fiddling all the time. Cable GX is so much more hands off

Reply

Onawalk

3 weeks, 3 days ago

How do you shift it then;)

Reply

Jerry Willows

3 weeks, 3 days ago

most AXS is sold on complete bikes. I've found the opposite with T-type.

Reply

Cooper Quinn

3 weeks, 3 days ago

It's true, no one ever fiddled with derailleurs before electronics got added.

Reply

Dave Tolnai

3 weeks, 3 days ago

I can't speak for electronics, but the amount of futzing required on a modern mechanical drivetrain these days is pretty minimal. I would say typically, once setup, there might be a few cable turns required once the cable stretches and that's about it. Even cable life is pretty good these days now that full housing is standard.

Reply

Cooper Quinn

3 weeks, 3 days ago

I agree, and would add the same about modern electronic groupsets. If you're futzing about regularly on rides... something is wrong.

Reply

Wapti

3 weeks, 3 days ago

This is the sort of article you don't get anywhere else.

Reply

hongeorge

3 weeks, 4 days ago

Very cool. Agree on the Lego vibes, my GX AXS is perfectly fine but I'm still tempted to buy this and spend a day building

Reply

Gage Wright

3 weeks, 3 days ago

I love this so much; rebuild, repair and sustain. Thanks for guinea pigging this for us Cam. I have about 3-4 different Shimano derailleurs in my bin of spares that could donate parts.

Then again, if Madrone is willing to provide support where the big S*2 just want more money for a whole unit then I would probably look at just buying the whole derailleur from Madrone and live a life of small pars availability. No better way to stick it to corporate waste culture than supporting their competitors.

Correction, sorry Cam :)

Reply

Perry Schebel

3 weeks, 3 days ago

totally. if i were ever possessed by the irrational urge to spend $500+ on a derailleur, that madrone bit of mechanical jewelry would be it. SO pretty.

Reply

Lynx .

3 weeks, 3 days ago

Perry, I'm very "thrifty" I guess you could say, I use XT level parts because back when I started, that's really where stuff started to last if you really ride hard/lots of miles/hours, these days though Deore works amazingly well and the price is amazing for what you get. That being said, there's not many things that I'd spend what I consider a fair chunk of change on, but that Madrone Derailleur is definitely one of them, in GREEN too please so that I can advertise that I'm not a slave to the Big Ss anymore. One caveat though, either refine the carbon cage so it looks like the ones pictured here for the SRAM derailleurs or make it work with these alu versions, because the one that was on there at Sea Otter was Ugly AF.

If by chance Madrone is looking for another project, they could try to replicate the "softness" of the Shimano SLX 11 speed shifter, but add the double click that XT has. All my bikes run on Shimano 10spd except one, it runs Shimano 11spd and after working on others 11spd Shimano XT equipped bikes, I opted to get the SLX shifter instead because the XT was way to stiff a push and I was right, SLX is so soft. Well as a bit of time passed, I came into possession of an 11spd XT and decided to give it a go, because honestly I do love and use that double tap trigger, but after a little while I decided to put the SLX back on to see if I was imagining the big difference, but I wasn't, the SLX stayed on, XT is in the spare parts drawer.

Reply

Dave Tolnai

3 weeks, 3 days ago

If you have a bunch of partial Shimano derailleurs, I would encourage you to pull them apart and see what you can piece together. I took an SLX with a mangled cage and mated that to an XT with a busted parallelogram. It all went together pretty easily and worked. Melding cage to body isn't that complicated. Beyond that though...

Reply

Morgan Heater

3 weeks, 3 days ago

https://zerodebikes.com/

Reply

Tim Coleman

3 weeks, 1 day ago

I bought one of the Madrone Link Kits when they came available. It was a 1 beer job for me to replace the broken links on my XO1 AXS derailleur. I also thought Aarons instructions were excellent. I also gained a new appreciation for some of the design elements of the original AXS derailleurs, the packaging of the servo into the derailleur is really elegant.

I've been riding the rebuilt derailleur for almost a month. With the Madrone kit the derailleur kit there is less play in the derailleur, and it feels stiffer, resulting in much better shifting performance. After the three days in the Whistler Bike Park, it's still as tight as new. All in all I'm impressed with the quality of this product, the tools and the instructions.

Reply

SixZeroSixOne

3 weeks, 2 days ago

It's cool/impressive that he's taken this idea to production but, from a purely business longevity perspective, is this sustainable?

The market for consumers to buy such a kit at those prices must be tiny, and it seems like a lot of effort that only serial tinkerers would be prepared to spend.

@cam: how many man hours in total did it take to get your derailleur back to a useable state?

I think a better business model would be to treat top end derailleurs (and maybe shifters?) as a serviceable item like suspension when regional specialists have access to Madrones tools for a wider variety of derailleur types and Madrone become the de facto supplier of specialist tooling (and/or offer the re-build service themselves)

I can't see there being enough volume of B2C sales (and if there was, there'd be much cheaper copies of those tools on Ali Express within weeks)

Reply

Perry Schebel

3 weeks, 2 days ago

i like the idea of specialty service shops (for more technical parts refurbishment) - though only viable if manufacturers are willing to play. ie, providing retail level small parts & schematics as required - which unfortunately isn't currently the case. that we've got increasingly more high ticket modular components that are more or less trash & replace (ie, said mechs, ebike motors, etc) is a shame - esp when many of these could be saved from landfill with a few (relatively) cheap bits & some expertise. as a consummate cheapass bodger, this kind of waste bothers me.

Reply

Lynx .

3 weeks, 2 days ago

And here we have it, the only in it for the god damn money crowd, absolutely CANNOT understand how anyone could possibly do something to not get rich as the outcome and instead just do it for the passion, maybe break even or make a small profit eventually

Reply

SixZeroSixOne

3 weeks, 2 days ago

Lol. You've no idea what you're talking about but let's not derail the conversation

Reply

Cam McRae

3 weeks, 2 days ago

It’s hard for me to estimate how long it would have taken me without taking photos and notes and thinking about process along the way, rather than just processing and doing, but I’d say doing it in about 90 minutes the first time is about right. I’m sure you could easily get it down to 20 minutes on a third try.

Reply

Dave Smith

3 weeks, 2 days ago

Would totally run this interesting and fairly seamless frankenstein...It's nice to see 3rd party industrial design mesh with a system beholden to committees and brand considerations.

Reply

Please log in to leave a comment.