First Look

Reserve: Santa Cruz's New Carbon Wheels

Santa Cruz did much to put Enve Composites on the map. The first time I ever rode Enve rims they were called Edge and they were mounted to a Santa Cruz V10 with 26" wheels. They were vastly stiffer than any rims I had ridden previously and the steering precision was intoxicating. Here we are seven years later and after spec'ing thousands of rims, Santa Cruz is bidding farewell to Enve and starting an in-house wheel program (but the Syndicate will be finishing the year on the Enve dime). Like everything bearing the Santa Cruz name, the rims were designed and tested by SC in California and manufactured in their carbon facility in Asia.

We had a couple of days riding two Nomad IVs with Reserve wheels a few weeks ago and one of them has been doing time under Pete Roggeman (above) Photo - Dave Smith

Rims are an automatic next step for any company that has tackled carbon frames. Specialized and Ibis were early to the party but Trek (with Bontrager) joined the fray shortly after as well as Intense earlier this year. The structure is vastly less complicated than a frame and the economic upside is significant. Not only can the retail price of a carbon-rimmed complete bike option be dropped by a stack of cash, the company can now reap fatter margins and sell the product in the aftermarket. And Santa Cruz is damn confident about their carbon-building super powers. When I asked Composites Engineer, Nic McCrae, who was the project leader, about the rational for entering the wheel market his response was; "It’s pretty simple—we thought we could do a better job."

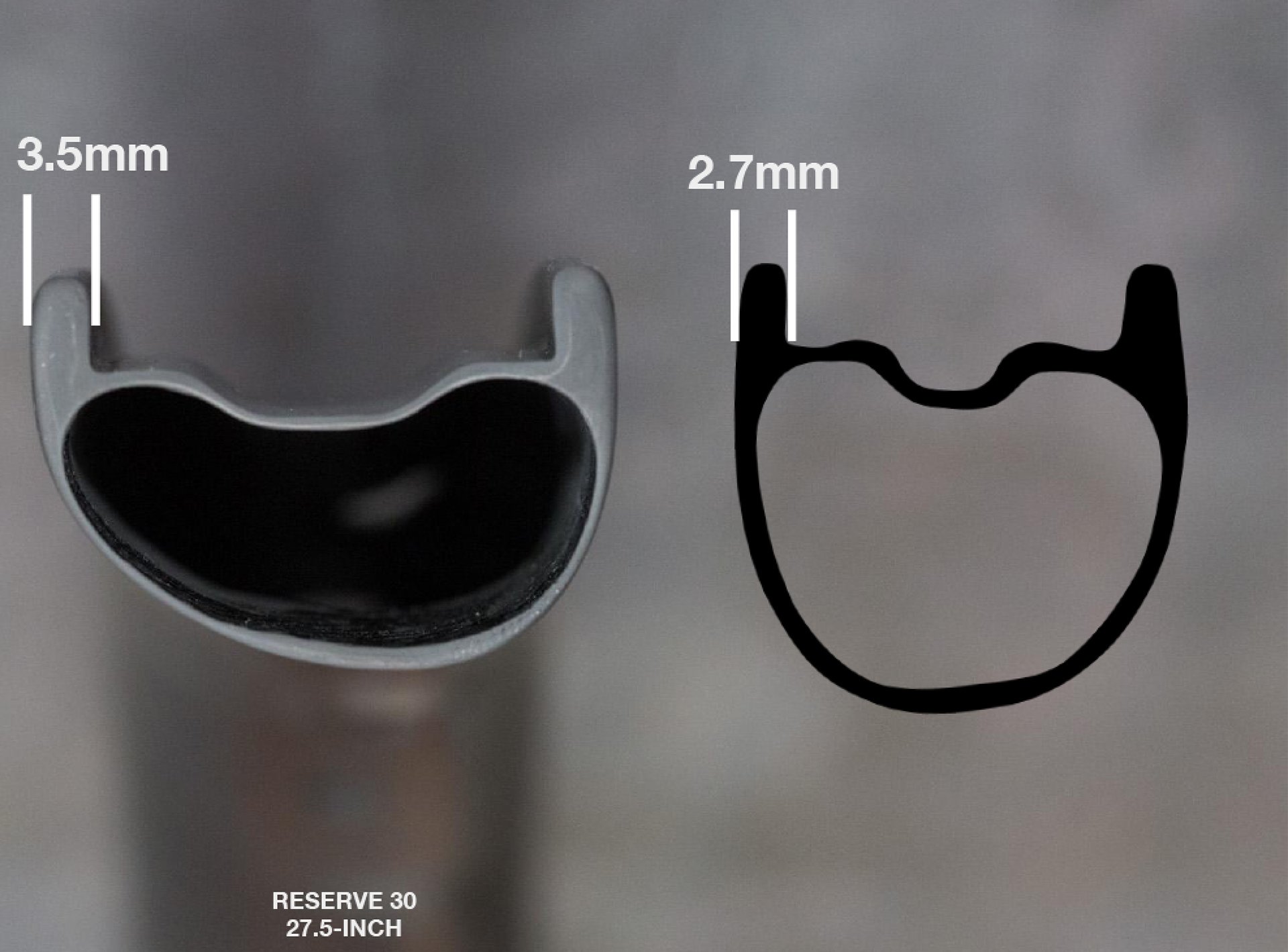

Reserve rim bead is 25% thicker than industry average according to Santa Cruz.

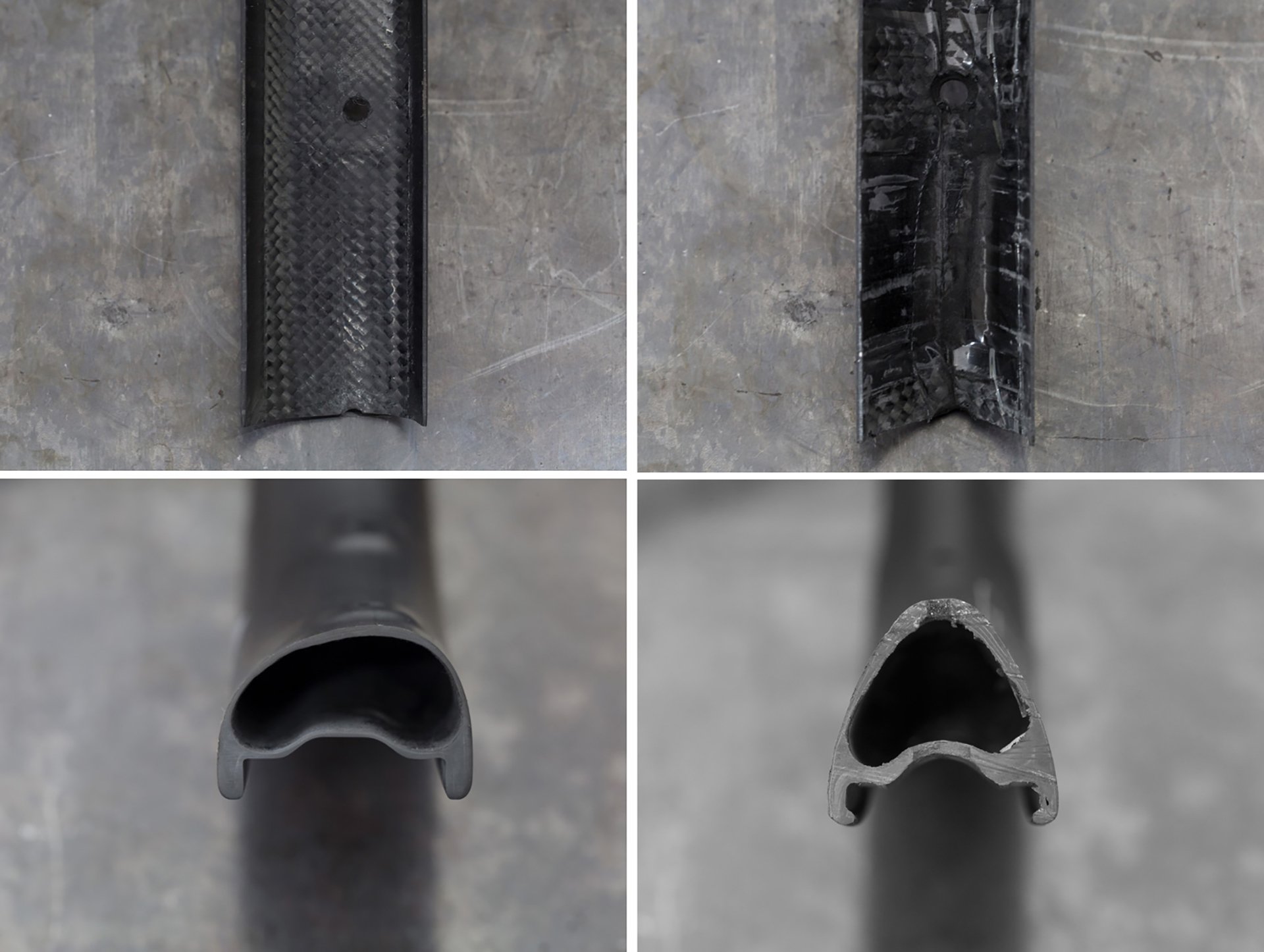

Santa Cruz tells us their warranty claims are among the lowest in the business and job one with the wheels was strength and reliability. The sidewalls are fatter than most other wheels I've seen for added burl. Beefing up the area around the spoke holes saved weight overall allowing for a smaller wall thickness between spokes. That weight savings was put into the rim bead where most failures occur. Santa Cruz tells us industry average is 2.7mm while the Reserve 30 in 27.5 is a full 3.5mm thick.

Santa Cruz Industrial Designer Jack Russell doing some product testing in B.C. on the Reserve Wheels. Photo - Dave Smith

Testing

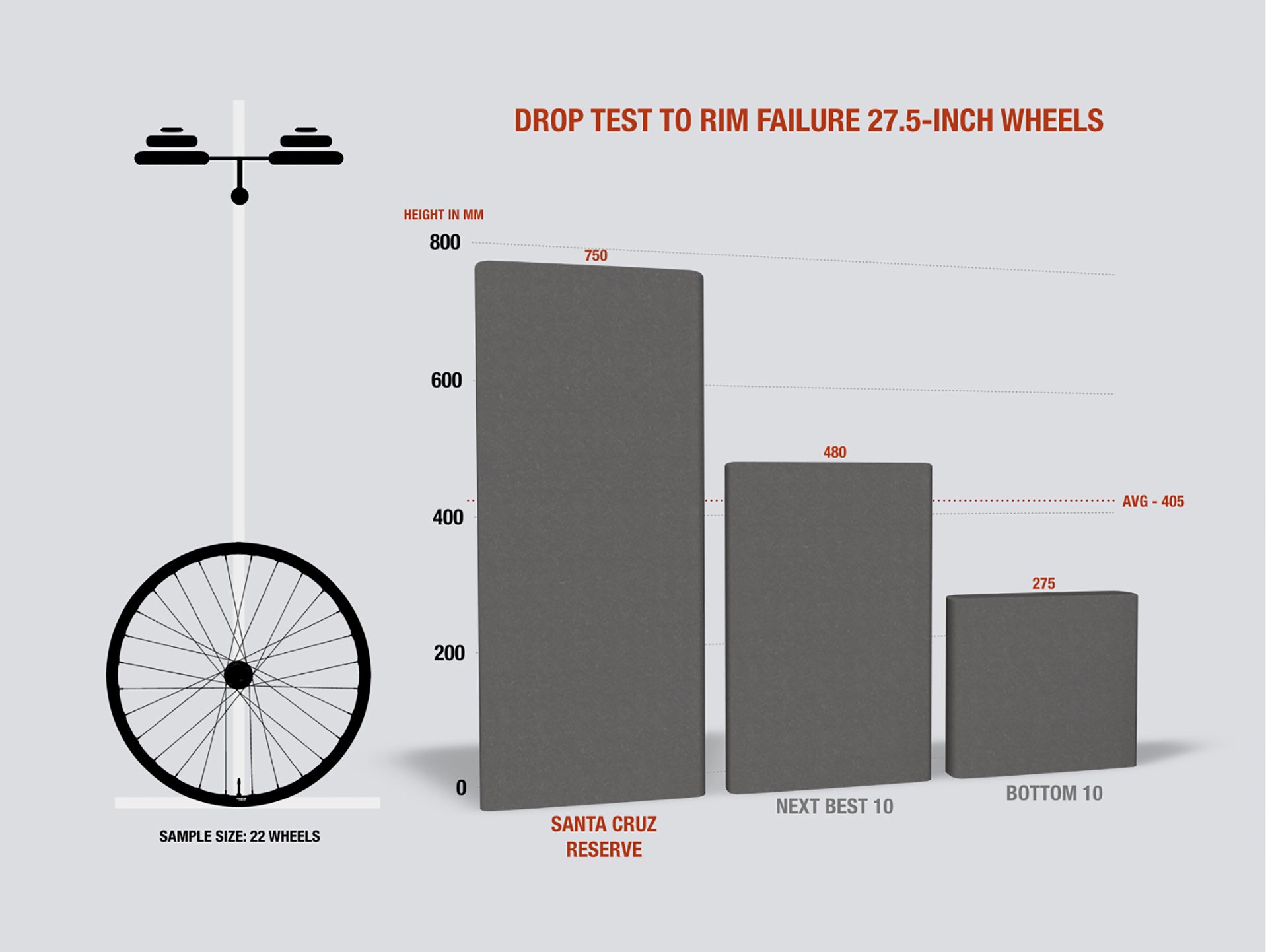

Testing has been a big part of the program and it was necessary to design some new test protocols. Santa Cruz determined that the most damaging impacts are those that impact one side of the rim at a time so an impact test that replicated that was implemented. And then they beat the hell out of Reserve rims and everyone else's. The number we were provided (see below) suggest that these are significantly stronger than anything out there. At Sea Otter a Bontrager representative tell me the same thing about their Line XXX wheels. Until we get some real time on these rims there's not much we can say about their ability to take a punch.

While the Syndicate remains under contract with Enve, Santa Cruz has been testing with Josh Bryceland and the 50:01 crew, Santa Cruz's enduro racers, and this guy. I guess Danny MacAskill is a decent product tester. Apparently he filmed all of a Wee Day Out on one set of Reserve wheels.

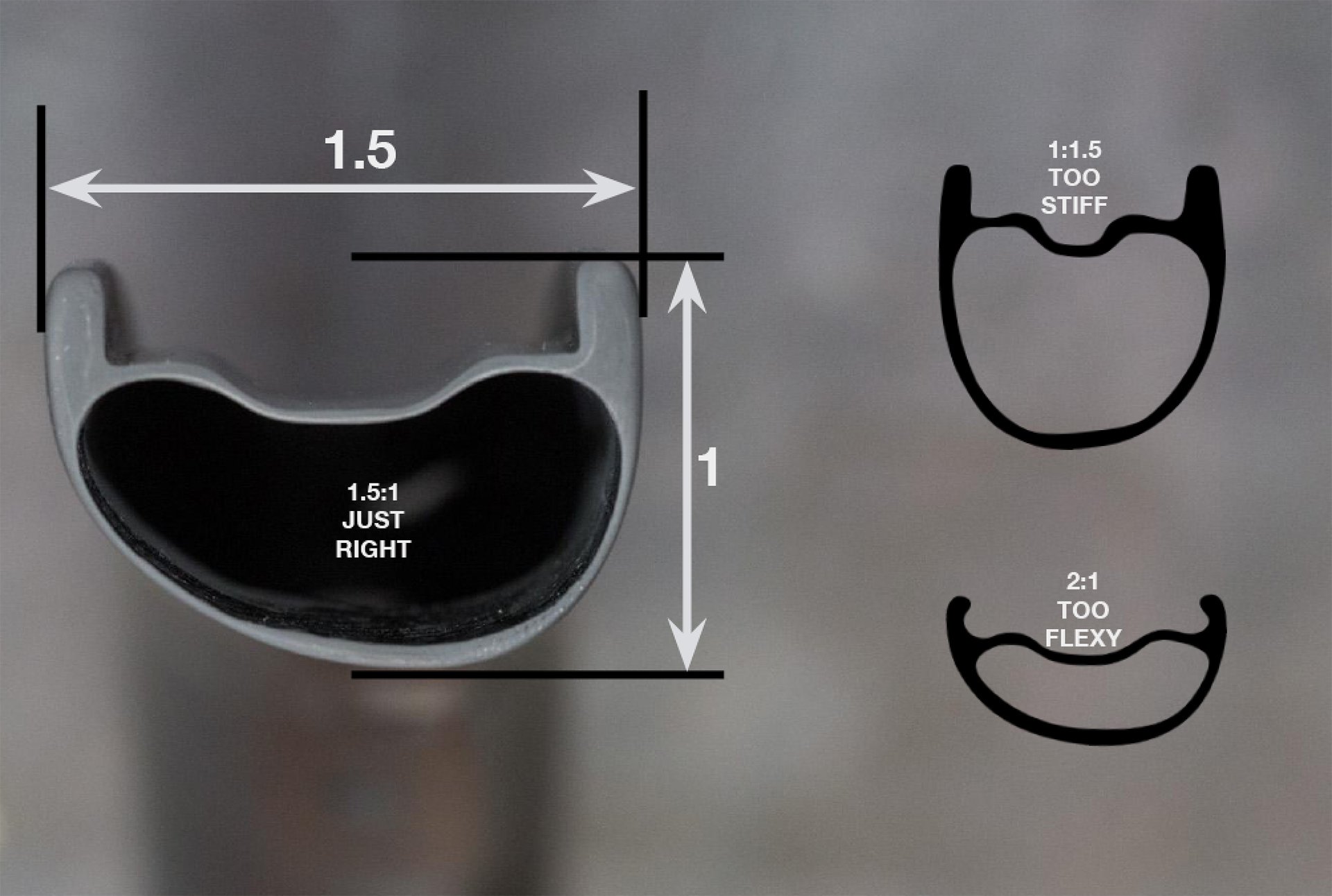

After strength and reliability, feel was next on the priority list. After many prototypes Santa Cruz decided the golden ratio was 1.5:1.

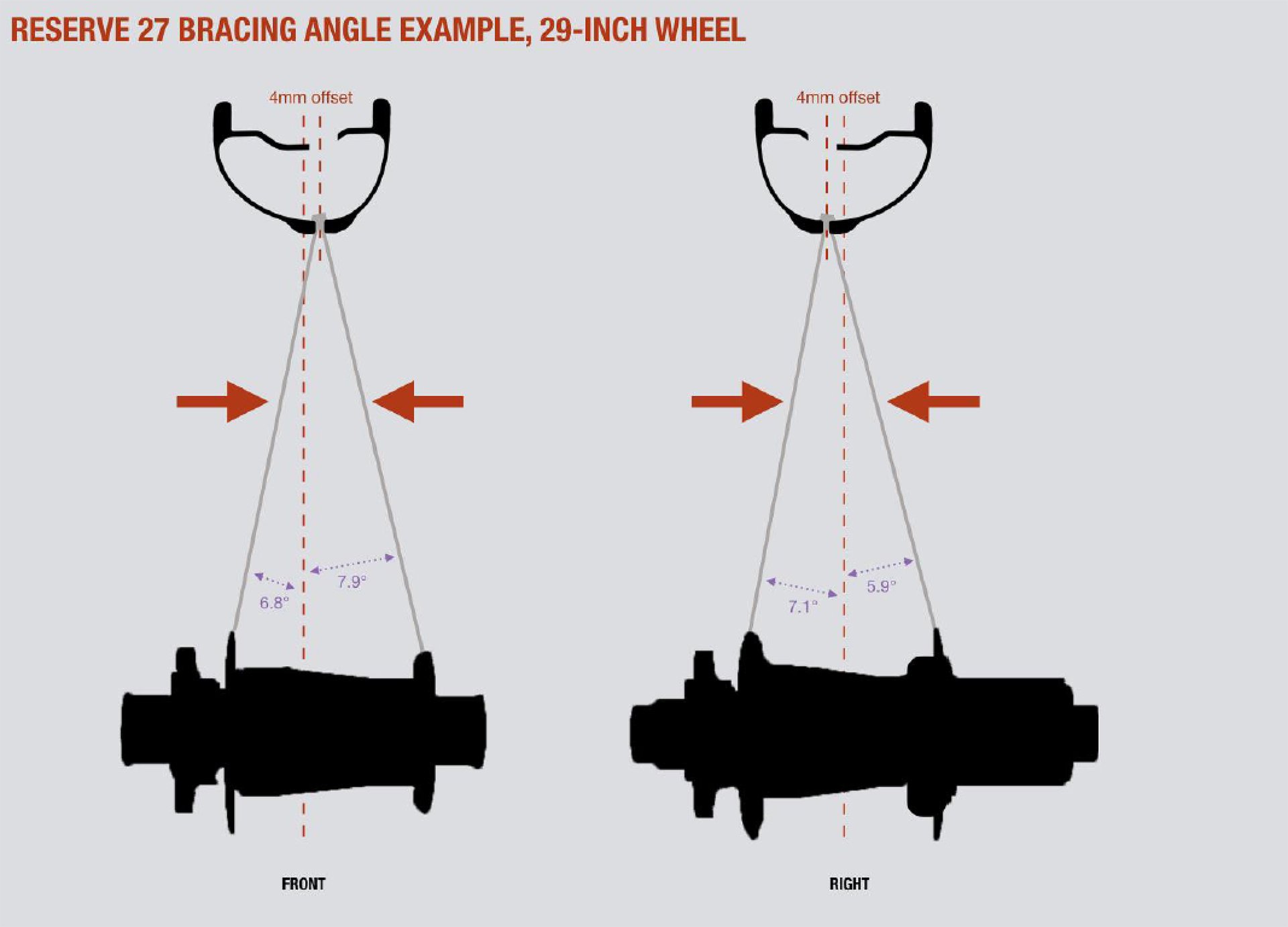

Asymmetrical spoke hole placement was chosen for even spoke tension and bracing angle.

The external spoke reinforcements are the most distinctive element of the Reserve wheels. They are said to add strength and improve drilling precision.

Santa Cruz provided these testing figures. Sometimes it pays to be last to the ball.

Busting rims for fun and profit.

12 Questions with Composites Engineer Nic McCrae

What can you tell me about your overseas carbon manufacturing facility? You seem to have been able to achieve a level of fit and finish that has eluded other manufacturers.

We partnered with a new engineering team in Asia and helped them to put together a brand-new factory exclusive to SC (for rims) where we could develop a rim-specific wax mandrel molding process in privacy. This process is how we got to the strength properties and finish quality we were looking for. In fact, we’re so confident in the quality we’re getting that we decided to offer a lifetime warranty on these rims, just like we do with our frames.

What was the biggest challenge you faced with this project?

Developing an impact testing machine and a testing protocol that could consistently recreate a trail-like failure mode. Most of the test protocols and requirements in play were ported over from road cycling which has a significantly different set of likely impact scenarios.

How hard is it to keep costs down with carbon wheels? What generally is responsible for the high cost?

It’s not easy, particularly if you’re advancing your own design like we are. Although we’re a little less expensive than others, our goal was more about production consistency and low-variability than price. We have low scrap rates and low (presumed) warranty rates which keep overall costs down, and that’s reflected in our pricing. But we didn’t start our carbon rim project by saying “how can we do this cheaply.” We looked at it from a quality standpoint first, then tried to work our way into a reasonable pricing scenario for what we feel is a among the best available product.

With frames there are CC and C options that reflect different levels of carbon material and construction, are there plans to offer tiers for wheels as well?

No, not at the moment. These are premium wheels and we wanted to start by making the absolute best product we could. But we will consider a larger range of products in the future.

What is the process to achieve the compliance you sought? How much happens in the test lab vs feedback from riders?

We started from rider feedback and then relied on lab data to understand which design parameters have the greatest impact on compliance. We designed the first rim prototype based on that information and then used test riders through the iterations to get as close as possible to the ideal balance of perceived compliance/stiffness and impact strength. Lacing pattern and spoke type also play a role here as much as rim shape and carbon layup.

How do you balance a feel that will appeal to most riders vs. the top level athletes who are sponsored by Santa Cruz?

You would be surprised how similar of a feel these different types are looking for. For 90% of us (pros and amateurs), the standard build is spot on. But then for riders with a very aggressive style of riding, wanting a stiffer wheel, you could increase the spoke gauge by rebuilding the wheel with DT Competition spokes (1.8mm) instead of Competition Race (1.6mm), for example.

I assume you rejected some early protos. What were the issues with the first rims to come out of the molds?

We made countless revisions actually. The Reserve 27 27.5” was the R&D platform for us, put the production version is actually the 4th molding tool for this model. Revisions were mostly about rim bead thickness and height, bead shelf diameter and bead well depth and profile.

How was the challenge of building and designing rims different from building and designing frames?

It’s a totally different ball game. A rim is a very simple shape, and you have way less design freedom since many dimensions are standardized, or very constrained. The manufacturing process was quite early on spotted as the key, and we designed a rim to work as best as possible with the process we selected.

Is the carbon material you use different from say the CC bikes? If so how does it differ?

In both frames and rims, we always use a variety of carbon grades and architecture. Most common grades are T700 and T800 carbon fibers, used as UD Tapes (mostly) and Woven fabrics (localized).

What element of the project are you most proud of?

That’s a tough one! But I feel like the coolest thing was to start totally from scratch. We had a pretty good background with carbon and manufacturing, and lots of experience testing methods, and we drew as much as we could from that. As an engineer, getting the opportunity to literally “reinvent the wheel” is a once in a lifetime opportunity, and I’m really proud of the finished product.

What have your experiences been like riding the wheels? For your riding, what do you appreciate most about them?

I personally love the way they ride. The right amount of stiffness for every type of riding. Combined with Comp Race spokes and the Torch hubs, they’re lively and snappy, but also great at tracking the terrain. I’m particularly enjoying the Reserve 27 29” on my HighTower.

Anything else you'd like to tell me about the project?

I think the one thing we’re really proud of is that we took the time to develop something truly unique. We could have rushed this to market a year sooner, but we decided to make sure to get all the pieces dialed and put something on the market that we’re proud to put the Santa Cruz name on. I know it probably sounds like marketing BS, but it’s really how I feel.

Composites Engineer Nic McCrae testing Reserve Wheels on a new Nomad in Triora Italy. Photo - Gary Perkin

The smooth interior structure is impressive - particulary when compared to the unnamed competing rim.

Another cutaway showing the wall thickness difference between the spoke reinforcement and the remainder of the rim.

Specs / Build details

You'll have a choice of either DT Swiss 350 or Industry Nine Torch hubs. Don't expect any new-fangled straight pull spokes. Santa Cruz wants you to be able to get spokes wherever you are so they are spec'ing J-bend DT Swiss Competition Race double-butted spokes with Sapim Secure Lock Alloy Nipples. The wheels will be laced 3X with 28 spokes per wheel by technicians at the Santa Cruz facility.

The wheels come with a lifetime guarantee and there will also be a crash replacement program with pricing TBD. The goal is to have you back on the trail as soon as possible.

It seems that someone cottoned on to the fact that it was going to be confusing to have 27.5" wheels identified at 27 and 29 and 29" wheels denoted as 25, 27 and 29 - but all the copy didn't get updated. The widest wheels will now be called 30 (not 29 as stated in the text below the image) - which reflects the inside diameter of that model.

Ride Impressions - Pete Roggeman

Today is a big day for Santa Cruz: they rolled out the Nomad IV, the Juliana version, called Strega, and Reserve wheels. Our Nomad tester came equipped with their new hoops, naturally, so we've had some time to roll on them. It's tough to separate out a lot of ride impressions about a wheel when you're also dealing with a new bike, and we never like to say too much about wheels - particularly expensive wheels - until we can comment on their durability. That said, the Reserve 30s on our Nomad are certainly stiff, but not harsh. They hold a corner well in rough terrain, and there is no discernible squirm or flex - testament also to the stiff chassis they're holding up.

The best test will be to run the Reserves back-to-back with another wheelset or two. We'll make that happen as a part of our testing, and also report back with more thoughts once we've spent more time on them. In the meantime, it seems safe to say that given the combination of careful design, Santa Cruz's impeccable track record with carbon, and factors like price, options, lifetime warranty, and weight, we feel confident in saying that they are a viable new contender in the premium wheel arena. If you're contemplating a purchase, you'd do well to factor in Reserve wheels.

Pricing

As an OE upgrade to a Santa Cruz build kit: $1,200 US. No word yet on pricing in other jurisdictions.

With DT Swiss 350 hubs: $1,599 USD

With Industry Nine Torch hubs: $1,899 USD

Availability

OE: July 1st - as the rest of Santa Cruz's updated lineup is rolled out (relax - mostly colours...or is it?).

Aftermarket - Wheelsets or rims only: Fall 2017.

Comments

Cr4w

7 years ago

A $1200 upgrade on a complete bike seems pretty reasonable.

Reply

Shoreboy

7 years ago

It seems less reasonable when the base model price is $6500 CDN. That would add about $1600 CDN to the price...

Reply

Wacek Keepshack

7 years ago

Upgrade, giving you nothing. May as well rub Snake oil into your thighs before the race to warm up your muscles.

Reply

Deniz Merdano

7 years ago

Oh man, so many things.....

First.. I recently received an email from Enve about god knows what, but I remember it saying, THEY were tha ones who put Santa Cruz on the map by producing their first and many carbon frames and parts for them. I remember reading it multiple times and being confused. But i also still miss read labels at grocery stores and buy the 'light' version of products accidentally.

Secondly, the graphic/marketing bro who made the illustrations should just GO...

Spoke bracing angle one with 'Front and Right' for hub labels? Cmon....

Also 'just right' is not a measurement for carbon strength, i don't even use it in the kitchen for cooking. Seriously..

Was this all rushed? Like the 29er release.. Is SC having a panic attack?

Just gimme WR1 wheels instead.

Ok im done

Reply

Pete Roggeman

7 years ago

Still got that email from Enve? I'd be curious to see it.

I'm a stickler for typos, but no one gets fired for them. Yes, they had a lot of stuff going on, maybe something slipped through.

What measurement do you propose be used? That's not for strength, by the way - even remotely. It's a reflection of the balance they sought between stiffness and compliance. "Too stiff", "Too flexy", and "Just right" make perfect sense to me. If they had inserted a unit instead, first, it would be utter bullshit, and second, there's nothing to compare it to, because other wheel manufacturers also don't include a unit of strength in measurement of their wheels. So...just looking for holes to poke, or what?

Reply

Wacek Keepshack

7 years ago

The inside looks good but lots of stuff here is just marketing bollocks for people who know absolutely nothing. How can a carbon rim be flexy once it has enough meat it can withstand direct hits? I recommend taking a light bicycle XC rim which is just above 300g and trying to bend that by just pressing it against the ground. Even lightest road rims are known to never get out of true, to rub on rim brakes in corners. So that's about right for Bullsht content. Then Mike Kazimer from Pinkbike cracks one...

C'm on SC, carbon rims are rims made of carbon fibre, they are slightly lighter than aluminium counterparts, that's the end of the story. You save more weight by using alloy nipples instead of brass ones, but why would you do that in the first place?

Reply

Cam McRae

7 years ago

Actually from my experience the real benefit of carbon is strength rather than light weight. And because, unlike aluminum, the material has no memory, it isn't struggling to retain its shape. Have you ever potato chipped a rim? That doesn't happen with carbon. And I'm not sure about your point with flexibility as it relates to strength. Flex relates most to the shape of the structure while the strength in terms of impact resistance is related to the material that is likely to impact the ground. As far as Kazimer breaking one goes, did you think Santa Cruz was saying they are indestructible? He clearly stated that other rims would have broken under the same impact and that it was rider error. Things break. Will these break less than others in the real world? That remains to be seen. It would be great if your average rider could get statistics on failures the way we can about vehicles but alas that isn't possible. You can talk to bike shop employees but they have their own biases.

Reply

Endur-Bro

7 years ago

These wheel sets are overpriced and overhyped.

Looks like LB did those graphic illustrations for SC. And speaking of LB, I'm fairly certain all my LB rims have been 3.5mm wall thickness. I see 2.7mm is an "industry average" which I guess works if you include the road industry. I suck at maths; but get the feeling that 3.5 + 3.5=7 and 33.5mm - 27mm=6.5mm and the other rims with a .4 and .6 OD measurement...

"Just right" sounds like the whole 650b goldilocks BS we were all fed a half decade ago...

Macskill used one set of wheels? Big deal, the "Road Party" video only destroyed one set of road wheels from that video.

Reply

Alex D

7 years ago

Edited.

Reply

Please log in to leave a comment.