Interesting take on through bolts through axles.

Through bolt stiffness

Interesting. Would've been nice to see the stiffness lab results he briefly mentioned. Also Dt Swiss 350 axle diameter measuring at 14.88 then being labeled 14.80 seems less than exacting.

Is there a risk of some kind in cranking the holy beejezus out of your axles? I actually don't do mine up all that tight, I suppose out of worry of squeezing the bearing or somesuch. I think recommend for mine is 15Nm, I doubt I get above 12.

I don’t think the through bolt needs to be massively tight. The ends are captured by the fork or rear triangle ends. I have had them come loose on rides though so doing them to spec should be what we do. I use my trail tool to tighten them because that’s what I’ll use if I need to pull a wheel on the trail for a flat or something.

To me the through axle thing was to address shitty quick releases which would not tighten enough and could allow the wheel to be levered out of the drop out with hard disc brake use. Shimano qrs seemed fine. Most other aftermarket qrs are shit.

Last edited by: andy-eunson on Jan. 30, 2021, 2:31 p.m., edited 1 time in total.

That's a pretty misleading video IMHO. Most MTB frames and forks use a slotted dropout that captures the endcap and takes the shear load. The through-axle really just needs to provide enough axial force to take up any play and keep the hub in the dropouts. Torque cap forks without torque cap hubs are an exception to this though. Also, Hydra hubs claim to have a tighter fit between the hub axle and through axle, although I don't know what the tolerance is. I have had issues with QR axles on disc brakes, and find the 12mm through axle holds the hub in place far more securely.

Something doesn’t follow here. On my last Fox 36 (2018?), the axle torque spec was just over 2Nm. I’ve been told very explicitly by Fox tech NOT to over-torque, but this guy says go to 12Nm. Hmmmm.

https://www.ridefox.com/fox17/help.php?m=bike&id=689#usingthekabolt

But for other systems like the Syntace rear axle in my Transition, or the 15mm through in my Manitou, what he says makes sense about the axle mostly being a clamping load.

Last edited by: JVP on Jan. 31, 2021, 10:16 a.m., edited 1 time in total.

Posted by: JVP

Something doesn’t follow here. On my last Fox 36 (2018?), the axle torque spec was just over 2Nm. I’ve been told very explicitly by Fox tech NOT to over-torque, but this guy says go to 12Nm. Hmmmm.

https://www.ridefox.com/fox17/help.php?m=bike&id=689#usingthekabolt

But for other systems like the Syntace rear axle in my Transition, or the 15mm through in my Manitou, what he says makes sense about the axle mostly being a clamping load.

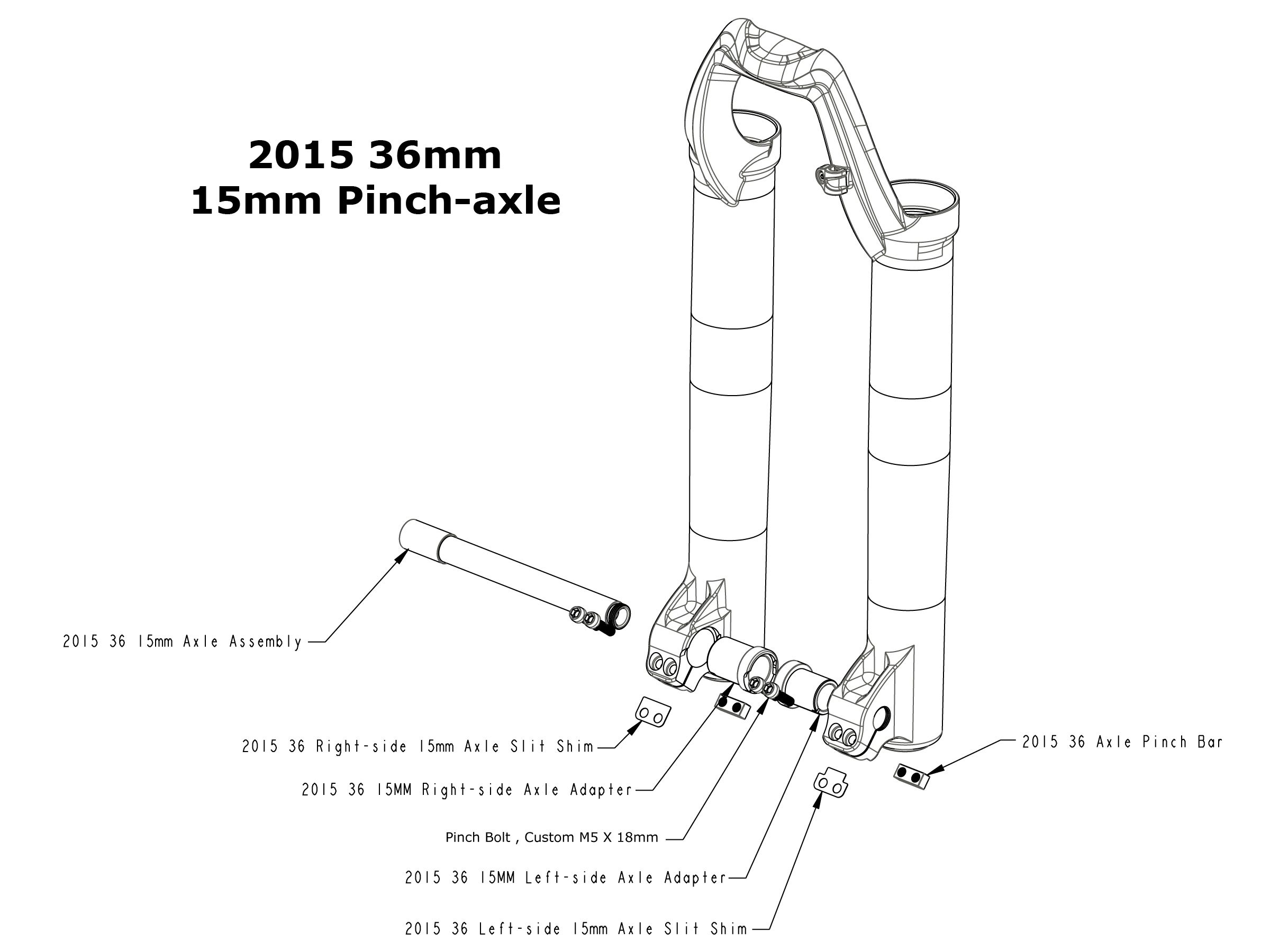

Are you referring to the pinch bolts?

Posted by: mrbrett

Are you referring to the pinch bolts?

No (well yes, those too), I’m talking about the front axle on non-QR versions of the fork. 2.3 Nm or something like that is the spec from Fox. It’s in that page I linked to.

That 2.15nm is for the pinch bolts on a floating axle.

The photo showing the kabolt has a drawing of the end of the kabolt that says 17nm on it.

You're confusing the two designs.

With a standard through axle you need enough torque to preload and slightly stretch the axle itself. This is not necessarily related to stiffness but this is just a function of the fact that all threaded fasteners rely on this preload/stretch to remain tight (unless you glue them in but I don't recommend loctiting your through axles. :-D)

Last edited by: Kenny on Feb. 1, 2021, 9:13 a.m., edited 1 time in total.

The old 36 and 40 with Kabolt are different, it appears. The one I'm talking about is an older design, so not super relevant anymore, but it's low torque and a floating axle design. I'm just posting this since I'm curious about Fox's thinking on this vs. the perspective of dude in the vid.

Direct paste from the Fox page I linked:

- Install the front wheel into the dropouts and slide the axle through the dropouts and hub.

- Using a 5mm hex wrench, torque the axle to 19 in-lb (2.15 Nm).

- Torque the two pinch bolts on the rider's left dropout to 19 in-lb (2.15 Nm).

- Compress the fork a couple of times to let the right side of the dropout float and settle to its low-friction point.

- Torque the two pinch bolts on the rider's right dropout to 19 in-lb (2.15 Nm).

I am still running a 135 Chris King rear hub with the 10mm bolts on each side. I use a long handle 8mm allen to tighten them down. The bearings run directly on the one piece axle. I went so far as to make a set of dropouts so I could keep running it with my current frame (Banshee). I think it's the stiffest setup I have, other than maybe the 14mm threaded one piece steel axle on the rear BMX hubs. I do swap it out for a 10mm thru axle wheel for light duty if I don't want to carry the 8mm allen.

I torque the Kabolt 15mm axle on the fork I use for DJ to 17 nm. If you look at the Fox 15mm QR axle, it actually has a 5mm rod that stretches like a classic QR.

For 20mm axles I'm a fan of designs with a thru axle like the CK (one piece axle) or OS DT 240 (end caps thread onto the axle). A lot of them have the inside bearing races running directly on the fork axle, depending on the fork design the bearings can spin the races on the axle or rattle around, especially with variation in axle diameter.

Forum jump: