First Ride

ZIPP 3ZERO MOTO Carbon Wheels (RIDDEN!)

Back in April of this year Zipp released their first mountain bike wheels called the 3Zero Moto. When NSMB first laid hands on these wheels at Sea Otter, we published this article here with loads more info.

Coleman's Notes; the rims are a carbon single wall design. The design is said to be Moto inspired, the goal being more vertical compliance than normal mountain bike rims. The thinking is that a vertically compliant wheel essentially adds suspension to your bike, allowing the wheel to more easily deform over obstacles on the trail. The intent is to improve traction, and reduce the impact forces transmitted through the bike.

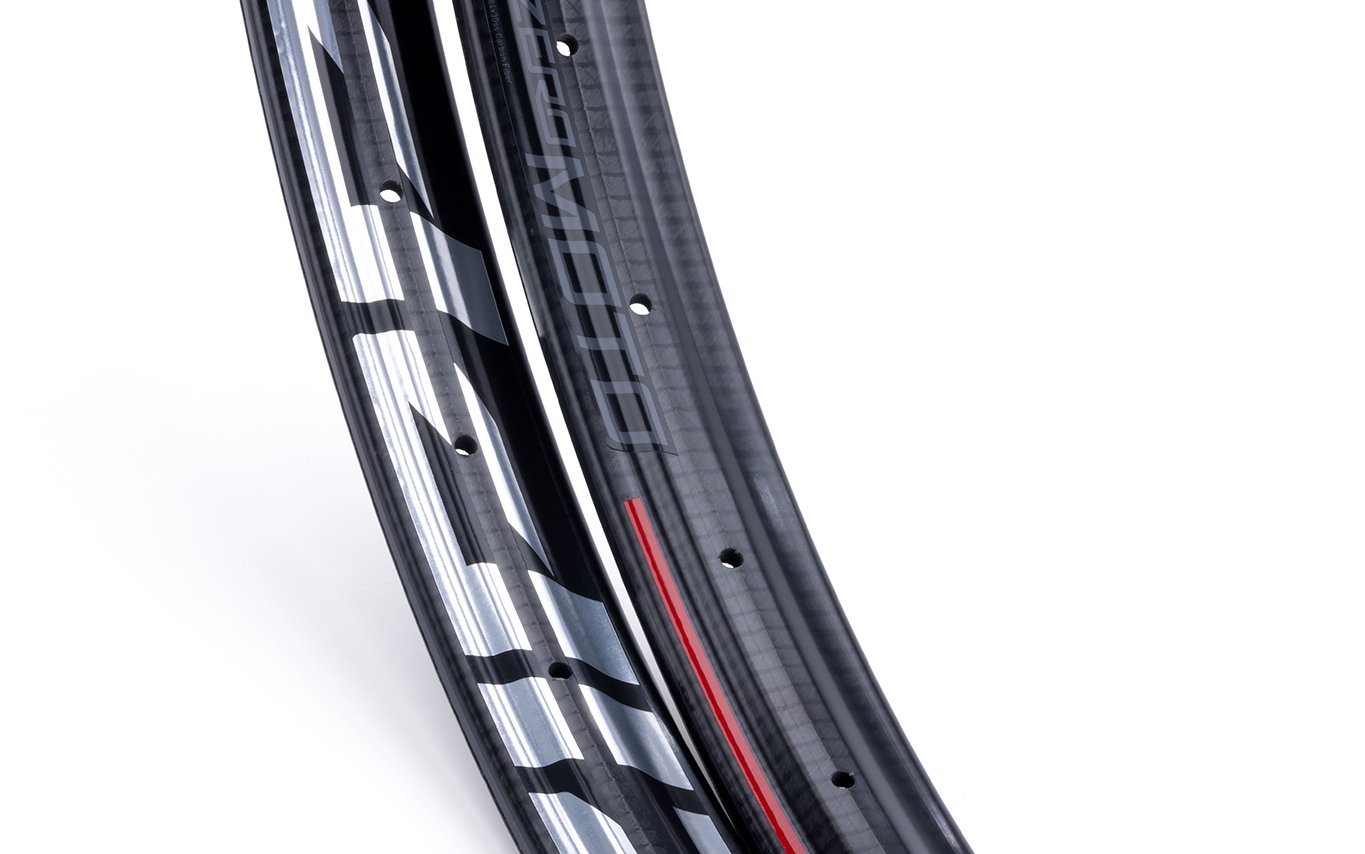

Zipp 3Zero Moto rims.

Technical detail recap:

- Moto inspired low-profile, single wall, carbon rim

- Intended use is trail and enduro

- Rims are manufactured by Zipp in Indianapolis, USA

- Available in 27.5 and 29 inch wheelsets or as rim only

- Rear hub has 52 points of engagement = 6.9 degrees engagement angle

- Wheelsets come with TyreWiz included

- Lifetime warranty with a 120 kg weight limit

- Weights: 27.5" - 1,825 grams // 29" - 1,910 grams

- Price: $1,999 USD

Zipp 3Zero Moto wheel.

TyreWiz comes standard in the 3Zero Moto wheels. This is normally a $200 USD spend, but the way it's packaged in to the 3Zero Moto rims is much more elegant than the standard TireWiz you can buy in the aftermarket. The idea behind TireWiz is you can check your tire pressure on your phone, or on your smart cycling computer. This can alert you if you're getting a flat, or if your tire pressures are falling outside of your preset window. TireWiz requires you to set an ideal pressure for each tire, and then a band of ± 1, 2, 3 or more psi depending on how OCD you are. I think the feature I'd use the most is to quickly check if my tire pressures are still in my window when pulling the bike from the rack, flashing green means good to go. It might be a bit gimmicky, and you probably don't NEED it, but I can see it being handy for some.

Green means SEND IT! The packaging of the TireWhiz into the 3Zero Moto rims is slick.

Riding impressions:

The SRAM guys told me to bring my trail bike along to Whistler Opening weekend. The weather was beauty and the lift lines were short so we shredded some laps on the Giant TRX 0 wheels I'm testing. Once the lines grew long we retreated to the shade where Jeff Bryson from Wheel Thing bolted a set of the new Zipp 3Zero Moto wheels to my bike. In the flesh the rims are beautifully made, and the finish is among the nicest around. Making these single wall rims is harder than you'd think, which makes the finish and quality of the Zipp wheels even more impressive. With wheels mounted, the time had come to get them out on the trail. We had determined our test track and the dirt in the bike park was primo.

The test mule Norco Range locked and loaded with the Zipp 3Zero Moto wheels. I like the subtle, but unique styling of the wheels.

Things got off to a chill start. Initially I found my groove on the new wheels and tires. Ideally we would have used my tires, but changing tires would have taken too long. I'm well used to the Maxxis DHF front and DHR2 though, and the traction was all time. The test track had a mix of all elements featuring loads of different corners, jumps, tech, flow, you name it. I was immediately struck with how soft these wheels feel on the ground. There is legitimately less vibration transmitted through the bike. In some situations this meant excellent traction, and more importantly these are really comfortable to ride.

As I built pace and load through the wheels I noticed the rear tire starting to lose traction where the front still stuck firm. I think what is happening is that under high cornering load the rear rim is starting to deflect, lose its camber to the trail, and the side knobs aren't engaging as aggressively. I noticed this in a few different situations, but most noticeably in high load, bermed corners. This affect is likely only under heavier riders that are hitting corners abnormally hard. I was listening in on the feedback of other riders, and the general consensus was overwhelmingly positive. Another thing that I noticed was that the extra compliance made the 3Zero Moto wheels feel less precise than other carbon wheels I've ridden recently. This is both a plus and a minus. While the compliance is excellent, the placement and communication of the tire and rim combination on the trail wasn't as good as I'm used to on stiffer carbon wheels.

You can see the 3Zero Moto rim vertically compressing in this photo and unloading the spokes at the 6'o'clock position.

More on the TireWhiz: After a sketchy side move, I slid back on the the trail and the rear tire made an awful tire carcass rippling noise from the load I put through the wheel and tire. Things got very sideways and I thought I had torn the tire off the rim. Sealant was oozing and it seemed I had burped a bit of air. The tire hand squeeze confirmed there was still air in the tire, but how much? The TireWiz was helpful, a quick glance at the valve stem. Green flash. "Braaaaap, let's shred!".

Setting up and checking the tire pressures with the TireWhiz is easy. The real time tire pressure monitoring on a smart cycling computer is pretty slick.

The Zipp 3Zero Moto wheels offer a very different riding experience to any other wheels I've tried to date. The 3Zero Motos provide excellent compliance and they feel very comfortable on the trail. I think for many riders this is going to be a noticeable improvement in comfort over stiffer wheels, and possibly in traction as well. However, if you're a heavier and more aggressive rider you might find more deflection than you'd ideally like out of the rear wheel.

The asking price of $1,999 USD isn't cheap, but with the inclusion of the $200 USD TireWhiz, and quality of the product, the MSRP seems inline with other top tier wheels. That said, this is a first ride impression based on 5 runs in the bike park. I'd love to try the Zipp 3Zero Moto wheels over a longer period of time to see how they hold up around these parts, how they ride with different tires, and also to test the ride characteristics over a wider array of terrain.

For more on the Zipp 3Zero Moto click here...

Comments

Perry Schebel

4 years, 10 months ago

engineered compliance is a neat concept; lots of potential there. would make sense to offer a couple layup options for different weight ranges / desired stiffness. also - with the degree of deflection shown in the pic, curious how stable the spoke tensioning will be.

Reply

Vik Banerjee

4 years, 10 months ago

Yes that'll be interesting to see what happens long-term. The rider's weight is supported by a few spokes at the bottom of the wheel not by the rest of the spokes in the wheel. So those spokes have to have enough tension that when the rim deflects upwards they are not fully de-tensioned or they will fail.

Zipp presumably put wheels through extensive machine testing and trail testing so they should be fine, but that photo showing the bent spoke doesn't look like it's a sustainable wheel design. Time will tell.

Reply

Cr4w

4 years, 10 months ago

I thought that when the wheel compresses the rider is hanging off the top spokes while the bottom spokes become detensioned. Can someone call Jobst Brandt?

Reply

Mammal

4 years, 10 months ago

I believe you are correct. Spokes have no strength in compression, so rider weight is supported by the upper spokes in tension (hense why the de-tensioned spoke in the picture didn't cause the wheel to fold).

Reply

Perry Schebel

4 years, 10 months ago

jb says that the decrease in tension of the lower spokes effectively support the hub. ie, measurement of spoke tension of a loaded wheel shows more of an lower spoke tension decrease than an upper spoke increase, so he postulates that the hub isn't really hanging off the upper spokes. tho as a radial system, isolating only top & bottom in discourse seems a problematic simplification. perhaps smarter minds can weigh in? haven't *really* put much thought into it, rather than a "huh, neat counter-intuitive concept".

Reply

Mammal

4 years, 10 months ago

It's interesting for sure, but just based on the geometry and material of a spoke, they sure wouldn't provide much support in compression. Further, the bottom ones wouldn't be in pure compression (bending forces as well) which would make them even more feeble, support-wise.

I'd love to hear more on it though. I'm sure there's some reasonable amount of "load sharing" going on between spokes.

Reply

Vik Banerjee

4 years, 10 months ago

Perry Schebel - this is correct. The hub is supported by the tension in the spoke or two at the bottom. These lose some, but not all tension when the rim deflects upwards at the bottom. The remaining spokes do not support the hub. A wheel being a tensioned structure has highest tension with no load on it. The loads applied by a rider lessen the tension on those bottom spokes.

Reply

Tim Coleman

4 years, 10 months ago

Vik wouldn't the spokes at the 12 'o clock position also increase in tension with rider weight?

T-mack

4 years, 10 months ago

When you hit something and the rim deflects, the lower spokes lose tension yes. What does the shape of the rim do though? It ovalizes, the spokes at 9 and 3 o'clock actually see an increase in tension, I would guess more so than the spokes at 12 o'clock. These rims sound like they're uber compliant though so maybe there's a very little increase in ovalizing?

Reply

Andy Eunson

4 years, 10 months ago

I think at 3 and 9 you’d see a decrease. Just thinking out loud, if the rim deflects at 6 say 5 cm to be extreme, I think the rim will pull in to the hub at 3 and 9? Or perhaps initially there is and increase in tension there as the rim attempts to ovalize but at a certain point the sides come in? This needs an engineer I think and that’s not me. Still. I see the merit in a somewhat compliant rim but I think spoke breakage will be an issue.

The specs for the rim say max tension is 125 kgf. Enve is 120. That is pretty high. Older Stan’s Crest xc Race rims were only 90 for comparison.

Reply

Vik Banerjee

4 years, 10 months ago

"When you hit something and the rim deflects, the lower spokes lose tension yes. What does the shape of the rim do though? It ovalizes, the spokes at 9 and 3 o'clock actually see an increase in tension, I would guess more so than the spokes at 12 o'clock. These rims sound like they're uber compliant though so maybe there's a very little increase in ovalizing?"

The rim doesn't ovalize. Only a small portion of the rim deflects upwards at the bottom the other 95% of the rim doesn't change shape and the tension on those spokes stays essentially unchanged.

Reply

Cr4w

4 years, 10 months ago

I guess now we're trying to figure out just how not-stiff we want our carbon wheels to be.

Reply

robnow

4 years, 10 months ago

And our handlebars (OneUP, WeAreOne) and our frames (Yeti), its a goddamn revolution.

Reply

IslandLife

4 years, 10 months ago

Next years "revolutionary" bike - https://www.youtube.com/watch?v=N39uwTykTQk

Reply

Andy Eunson

4 years, 10 months ago

The spokes will require something to keep the nipples from loosening off when all the tension comes off the spokes as shown in the picture. Being a single wall means the rim tape will offer some assistance in that regard. Spoke breakage from all that detensioning and tensioning will lead to earlier failure. Zipp will need to use really good springy spokes to minimize fatigue related failures.

Reply

JVP

4 years, 10 months ago

My thoughts exactly. Going to be a lot of blown nips and spokes with these.

Maybe we'll go back to the days of loctiting our nipples on in a pinch to keep our wheels alive for a for a few more WBP days. Oh man, the early 2000's were fun. The clapped out crap we used to run...

Reply

slyfink

4 years, 10 months ago

Couple of questions:

"There is legitimately less vibration". Less than what? Carbon rims? Aluminium rims?

Re the deforming rim and de-tensioned spokes: straight gauge? butted? tension?

(not trying to be snarky, these are honest questions)

Reply

Tim Coleman

4 years, 10 months ago

@slyfink I suppose that was a bit ambiguous, but I was hoping it would be clear that the subjective impressions were relative to the baseline laps I did on the Giant TRX 0 carbon wheels. That said I've ridden those trails a ton on a variety of rim and tire combinations and the compliance of the Zipp 3Zero Moto wheels is noticeably higher than any other wheel I've tried. Aluminium rims could not achieve the level of compliance of the Zipp wheels without permanent deformation.

Zipp has a decent amount of technical information here: https://www.zipp.com/wheels/3zero-moto/

According to their specs the spokes are Sapim D-Lite J-Bend spokes that are double butted; 2.0 / 1.65 / 2.0. I don't see spoke tension info anywhere.

Reply

slyfink

4 years, 10 months ago

Thanks Tim.

it's what I assumed, but wanted to be sure. I also was curious about the comparison to aluminium. It's the main argument I use to avoid lusting after carbon ("they're just trying to mimic the feel of aluminium, so why would I pay more for just a few grams - and even there, some strong AL rims are just as light?!")

I'm looking forward to reading more of your thoughts about the traction benefits... (I'm a heavier rider too). I wonder if there's too much of a good thing?

Reply

Tim Coleman

4 years, 10 months ago

Having spent the last two years almost exclusively on carbon wheels I'll say that my recent experience being back on aluminium rims was aweful. I have some DT 511 rims on the DH bike, same tires and tire pressures as normal. Second run and I pushed a spoke through the rim tape, denting the rim and getting a flat. Pulled the dent out as best I could, retaped the rim, trued and retensioned the wheel, rode a few laps, trued and retensioned the wheel. Second day, trued and retensioned the wheel. Inflating tires was tough because the rim is a bit too small. Total pain in the ass.

In two years of carbon wheel abuse and not a single wheel out of true, and I'd almost taken it for granted. Inflating tires tubeless is effortless. Given the reliability and minimal maintenance on carbon wheels I can't afford to go back to aluminium rims. The performance and weight benefits are almost secondary at this point.

Reply

Metacomet

4 years, 10 months ago

Very cool concept with these rims. I like the compliance theory, and I think it could have more and more benefit the more natural the terrain becomes. But they are in a tough segment with these currently though, as the weight and premium cost is going to be a big sales hurdle if the benefits of the design are most in line with technical back country natural terrain type of rider. Perhaps too compliant to be smashed into all the things things at bike park speeds, and loaded up into hard packed bike park berms and blown out trails. A bit too heavy to appeal to a weight conscious trail rider. That leaves a small market in the middle and a tough competition with perfectly capable and affordable alloy rims at an equal weight. The extra compliance really has to pay dividends in the experience, and the wheel system better be bombproof in order to attract and keep customers in that space.

Reply

Jerry Willows

4 years, 10 months ago

How much do rims actually move on the vertical plane when riding? I think very little and definitely not noticeable. The tires are going to compress way more than the rims for compliance. More junk science from the bike industry.

Reply

Tim Coleman

4 years, 10 months ago

Jerry I'm with you on this for virtually all the other wheels I've ridden. I've always been surprised about folks going on about wheel compliance through 30 mm of tire deflection and 180 mm of suspension travel. I always thought maybe I wasn't perceptive enough to pick up on the differences. But these Zipps were noticeably softer than other wheels I've ridden. I'd love to see more objective deflective tests from manufacturers so we can see how various wheels stack up in terms of vertical, torsional and lateral deflection for given loads.

Reply

Jerry Willows

4 years, 10 months ago

I would really like to know how much the rim moves given same spoke count and tension between wheels. I bet an average rim only moves a couple of mm. Lateral movement would be vastly different imo.

Reply

robnow

4 years, 10 months ago

Jerry, have a look at the Nox Composites website under Technology-Wheel Building (Vertical Compliance and Carbon Rims), sorry, can't attach link for some reason. It exactly supports what you think.

Unless I missed it though, doesn't Zipp state more of a twisting deformation (not just compression) of the rim as well along the vertical plane...so maybe there is more deformation at the corners than we think, like maybe 10 mm?

Edit: "Ankle Compliance" as stated by tdc_worm below and on Zipp's website.

Reply

Jerry Willows

4 years, 10 months ago

Zip states that:

Coleman's Notes; the rims are a carbon single wall design. The design is said to be Moto inspired, the goal being more vertical compliance than normal mountain bike rims.

#junkscience

Reply

UFO

4 years, 10 months ago

https://www.noxcomposites.com/wheel_building#vertical

Reading that makes sense to me, especially seeing the mathematical proof. BUT

I'm also wary of any definitive statements made. When enough experienced riders who's impressions and opinions I respect and trust can tell us anecdotlly that while all other variables are controlled to the best of our abilities, and differences in ride qualities ARE there, there is more going on in the system than what mathematical formulas are telling us at this point.

Or maybe I'm just a sucker for marketing hogwash.

Reply

Tjaard Breeuwer

4 years, 10 months ago

For road wheels/tires Silca has a fair bit of info on their blog (from when Josh Poertner was at Zipp actually) about vertical deformation of tires and rims.

Reply

Jerry Willows

4 years, 10 months ago

as Tim mentioned, MTB's have big tires and big suspension. Curious on how much movement is on a road bike?

Reply

Andy Eunson

4 years, 10 months ago

In the photo above that rim has deflected enough to bow a spoke or two. Those spokes will have zero tension and go back to whatever tension they were at before the hit. Do that enough and that spoke will fail at the elbow in all likelihood.

Reply

Perry Schebel

4 years, 10 months ago

random: the profile reminds me of the plastic acs z-rims of bmx yore. now those things would deflect:

Reply

BeesIntheTrap

4 years, 10 months ago

I gave these a go the same weekend, took them for a rip down Crazy Train and Hey Bud. I didn't notice the rear losing traction before the front, but I only weigh 140lbs. They felt nimble and tracked better than my current E13 TRS wheels. Comfy for sure. Hard for me to give any insight into how much better or worse they are than any other carbon wheels though I've not ridden any other.

Reply

Tim Coleman

4 years, 10 months ago

Crazy Train and Hey Bud wouldn't have the type of corners or loads I'm referring to. Where I noticed this most was on tight, high load, well supported corners like on B-Line, Ninja Cougar etc.

Reply

BeesIntheTrap

4 years, 10 months ago

Ah, gotcha. Can't say too many of the trails I ride have corners like that on, so it's a bit of a muchness for me personally.

Reply

Timer

4 years, 10 months ago

Did they tell you for what rider weight and riding style the "compliance" is supposed to work and if you are close to that weight and style? Those rims are effectively fixed rate springs, by definition they will only work properly for a narrow range of weights.

Just out of curiosity, what tires were you running on each wheelset exactly? And problably equally important, what pressures (at least down to single psi). When considering vertical wheel compliance we are talking single digit milimeters. A pressure difference of one PSI might have a larger influence on vertical compliance.

Reply

Tim Coleman

4 years, 10 months ago

There was no mention of rider or style that the wheels were optimized for. They did mention a 120 kg weight limit, and they were reluctant to put a set of wheels on my DH bike for testing.

Tires on the Giant TRX 0 wheels were a worn out Schwalbe Magic Mary Super Gravity 2.35 x 27.5 Ultra Soft front at 23 psig and semi new WTB Break Tough Casing 2.3 x 27.5 High Grip at 28 psig. Tires on the Zipp 3Zero Moto were new Maxxis Minion DHF EXO MaxxTerra 2.5 x 27.5 WT at 23 psig and Maxxis Minion DHR2 EXO MaxxTerra 2.4 x 27.5 WT at 28 psig rear. Casings on the Maxxis tires are definately thinner and more compliant than the tires on the Giant TRX 0 baseline.

Reply

awesterner

4 years, 10 months ago

I’ve seen a broken one already in Bellingham, under a rider that is maybe a buck fifty :)

Reply

tdc_worm

4 years, 10 months ago

Is internal tire pressure localized or does the entire tire pressure cycle up and down as volume changes with tire impact? If its not localized, then the "ankle compliance" is only being exercised when we have a rim strike (assuming our tires sidewalls are not stiff enough to deflect the rim). i have a hard time believing that we engage "ankle compliance", unless the tire is bottomed out. my guess is that if we are regularly taking advantage of "ankle compliance," we should probably increase our tire pressure. I am a fan, however, that it could potentially be a safety net to avoid pinch flats.

on the vertical compliance and spoke loading/unloading vs spoke fatigue and failure, i suspect that it is highly present in any wheel that has give. here is a pretty cool video of WR1 doing some impact testing. note that the failure where the spoke pulled through is very close to the unloaded spokes.

https://www.youtube.com/watch?v=bgOb7__9FYs

my only uneducated concern with these wheels is that an unloaded spoke is going to routinely put pressure on rim strip and rim tape causing premature tape failure and a loss of pressure. all in all, i like the theory. if they are low maintenance, durable, and add a degree of pinch flat protection without using an insert, count me in.

Reply

Jerry Willows

4 years, 10 months ago

also note that the rim only deflects a couple of mm's after a huge impact so by Zipp saying that their wheels have more vertical compliance is hogwash.

Reply

trumpstinyhands

4 years, 10 months ago

The author of this article talks about vertical compliance but when I sat through a presentation on these rims from Sram I can't remember it being mentioned at all! it was all about twisting motion and not deformation at the actual spoke interface. It's that twisting motion (like an ankle as mentioned somewhere above) that allegedly provides the compliance, not up / down movement.

Reply

tashi

4 years, 10 months ago

Although a few mm may seem like very little, but it might not be “hogwash” if the difference between a really stiff (say early Edge/ENVE) and a really soft (I dunno, doublewides?) is only a matter of mm. It may not be much deflection in absolute terms, but i wouldn’t be too surprised if rims just don’t flex very much in general, making a small amount of flex translate into a perceptible difference.

Reply

Timer

4 years, 10 months ago

Could it be that what most riders feel simply isn't vertical but diagonal or even lateral compliance?

Most impacts are not straight vertical.

Standard carbon rims have enormous lateral stiffness compared to aluminum, which might be what riders experience as "harsh". Vertical stiffness of the entire wheel is pretty similar between carbon and aluminum outside of huge, rim shattering impacts.

Therefore the cool new thing about carbon rims seems to be to make them just soft enough that it doesn't negatively affect tracking too much but has enough diagonal give for a nicer ride.

Reply

Lev

4 years, 10 months ago

They are heavy for expensive wheels and I (now) would never ride without a tyre insert, adding even more weight. Riding pricey carbon and no insert means you may as well flush your cash down the bog. Stans Arch with inserts works well for me and I'm 110kg (240 pound) and a pretty hard rider. I can't really see the point in them.

Reply

BeesIntheTrap

4 years, 10 months ago

I run cushcore and the SRAM folk reckoned you didn't need them with these wheels due to the design. I'd love to take their word on that, but it's a big ask when you're paying so much for the rims.

Reply

Please log in to leave a comment.