Internal Brake Routing?!

Remove your fork. Roll up some bubble wrap. Shove it into your frame through the head tube. I mean, how much weight does bubble wrap add?” ~ Estevão* on how to fix ‘death rattle’ from internal brake routing.

Internal Cable Routing

If you despise internal cable routing – especially internal brake routing – like I despise internal cable routing then you’re a crotchety old retro-grouch with no aesthetic sensibilities. You’re welcome.

The masses have spoken. Internal routing looks better – way better. It’s reflected in bike sales to the point that almost every company, even those that were resistant, is now on the bandwagon. Whether that’s Santa Cruz and their sweet internal housing guides molded into their frames, Rocky Mountain and their ample, and adaptable, access ports, or most companies’ method of drilling a few holes in their frames and plugging some rubber grommets into the exit points.

From a mechanic’s perspective, Rocky Mountain has some of the best internal routing going. Big access points with adaptable covers make it fast and easy to change cables – maybe faster and easier than zip tie intensive external routing – on all their bikes. Like all internally routed brake lines, best practices are to bleed brakes any time a brake is removed and installed.

Okay. I give up. Route the shifter and dropper post cables internally. No problem. I’m over it. Yeah, it looks sweet. But… internal brake routing?

Internal Brake Routing

What a pain in the ass. Best case I’m bleeding a brake every time I do a removal and install. Worst case I have to cut the line to take my brake off because the brake fittings don’t fit through the access points. And the noise. Death rattle.

Heck, Santa Cruz has arguably the best internal routing. By that I mean it’s on par with good external routing at who knows what additional cost to frame manufacturing and the exit points are well positioned. There’s a reason they still strap the brake line externally.

Pivot’s bikes have very well thought out internal routing. It’s of the ‘hole-in-frame’ variety but the access points are large enough to make easy cable changes and the covers lightly pinch the cables to eliminate the ‘f*cking death rattle’.

Fine. Internal brake routing is here to stay, too. It simply looks that much better. Eventually, every company will figure it out. Rocky Mountain, Trek, and Specialized all provides tons of room for a mechanic to get brake fittings in an out and zip tie all the cables together to silence them.

Just stuff your frame full of that moto foam that Sam Hill’s mechanic uses” ~ Mikko*

But what about all the frames where internal routing consists of a few tiny entry and exit holes with the cables free clacking in the downtube? Argh.

Rubberized inserts are all that keep the internal cables in place on the NSMB Intense Primer Pro test bike. They do a good of keeping the dropper post and rear derailleur cable quiet but the brake line rattles around like someone dropped a couple of ball bearings down my seat tube. Intense is FAR from being unique in this case.

The Silencer.

Okay. I admit it. I’m a cheeky, sardonic, opinionated contrarian. My original plan was to write an article about how to “fix” internally routed brake housing by removing the rear brake from my bike and using a plethora of zip ties to just mount it externally along the down tube.

I wish I had captured the facial expression of internal routing lover ‘Bikeroom’ Jeff Bryson when I told him my plan. “Why don’t we have a beer and think about it” he said between dry heaves.

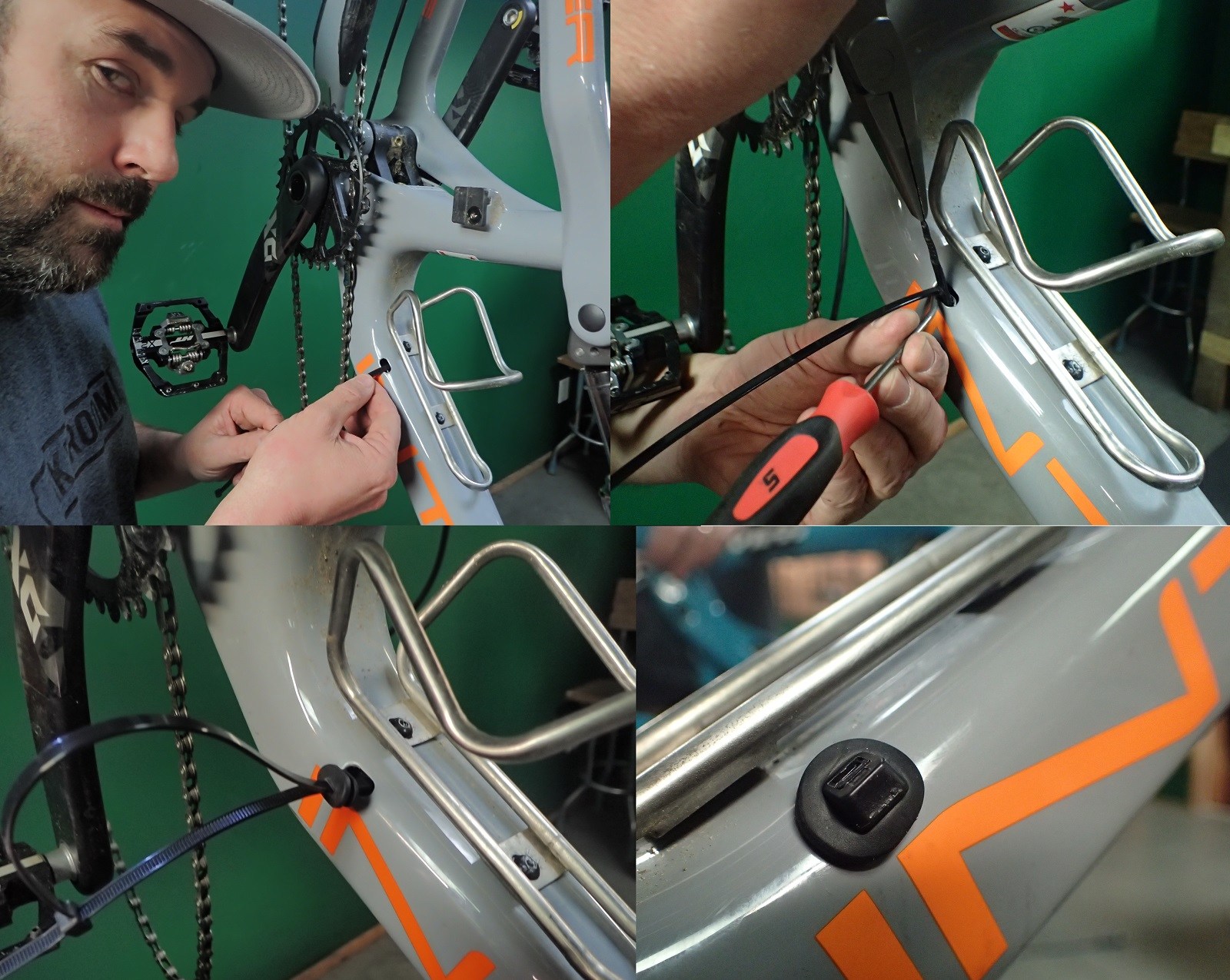

Jeff’s simple plan. A zip tie through the front derailleur exit hole that would capture the derailleur cable, dropper post cable, and disk brake line together to eliminate maraca madness.

Just drill a few holes in the down tube and zip tie the brake line inside the frame.” ~Gjurd*

After a few suds and some banter about options, Jeff set to work on his plan; using the tiny exit hole meant for a front derailleur cable to capture the three cables running inside the frame (dropper post, rear derailleur, rear brake) together to eliminate noise.

Tools of the trade: A zip tie. A rubber fitting. A Snap-On pick and pliers. A ‘shut-it-Andrew-I-know-what-I’m-doing-you-cheeky-prick’ facial expression.

As it turns out one zip tie, and a bit of stink eye, is the difference between the cable crowdy-crawn and sweet serenity.

The bigger the exit and entry points for the internal routing the easier it is to gang the cables together.

SRAM ‘Bleeding Edge’

SRAM’s Guide brakes are not my personal first choice and their Level brakes live up to SRAM’s “XC and Trail” billing – under-powered for local riding on a slack 140mm travel 29’er.

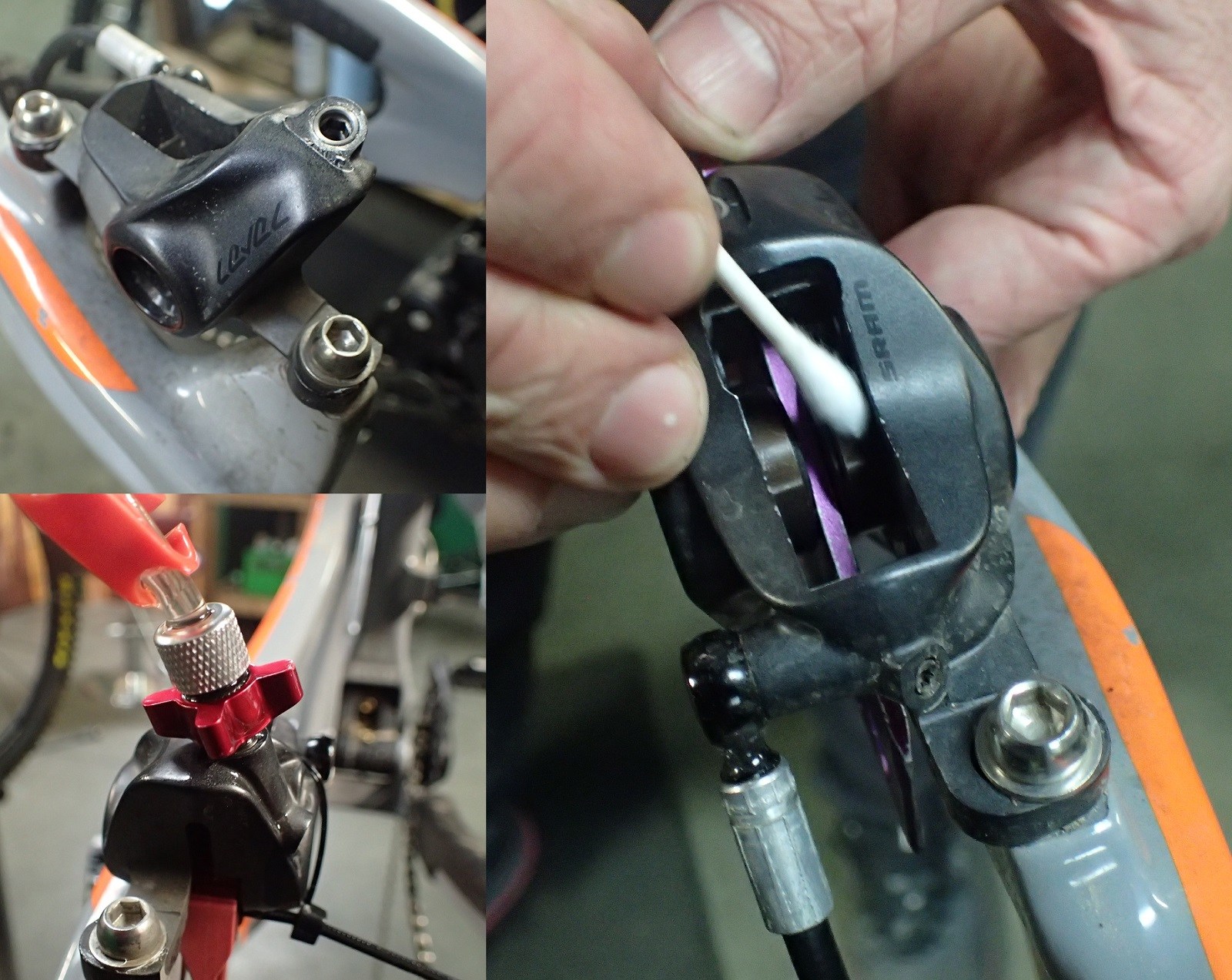

I would still like to re-iterate that their new caliper bleed fitting is the gold standard that every other brake company should be looking to. Perfect bleeds every time. A potential time saver when it comes to internal brake routing.

For best performance push the pistons out a to clean them semi-regularly. At least every time pads are changed. SRAM’s Bleeding Edge port in the caliper is the gold standard that every other brake manufacturer should look to.

Things that make Jeff smile: Internal cable routing and bleeding SRAM brakes with their Bleeding Edge port.

Problem Solved

Internal routing looks better. No argument. It’s hard to dislike it quite as passionately when it’s dead silent. I’d still prefer zip ties, or the option to choose between well designed and cleanly implemented internal and external routing on a given frame.

Barring that, I’ll settle for no internal brake line drum track.

*Names have been changed to protect the hacks at Wednesday night Bench Time.

Quiet bikes are faster.

Comments

brente

7 years, 3 months ago

Don't get it, bike have cables and hoses do not understand going to all this trouble to hide them. another solution for something that really isn't a problem.

Reply

ZigaK

7 years, 3 months ago

I was a fan of zip tying everything on the outside, until the time I was building up my current bike. I didn't have any zip ties lying around so I used clear adhesive tape as a temporary solution. It's still holding strong after 2 years. 🙂

Reply

Rexroth

7 years, 3 months ago

Couldn't fit zap-straps through the narrow opening on my Patrol, but I did have some thick double sided tape lying around. Hopefully this will work whenever I do get a chance to get out for a ride

Reply

Jonathan Harris

7 years, 3 months ago

I don't mind gear cables running internally but brake ones with stupid little holes so you have to remove your fittings is just dumb in my mind. Makes for a load of mess, way more work and way more swearing as I'm fishing around my downtube trying to retrieve the thing.

I actually quite like the external/internal combo on the Evil bikes. The brake is totally external and under the top tube with the rear derailleur cable which then goes internal through the rear triangle. That's just sensible to me.

Reply

taprider

7 years, 3 months ago

You can add another internal hater to the list

It was tried and failed back in the 1980s, even for fixed internal routing such as the current Santa Cruz, was ok at first but after a season in the mud became a real problem and had to use frayed cable housing attached to a drill as a roto-rooter

I like Rocky's 2011 bikes with all the cables and hoses routed on top of the down tube, looks cool like a base guitar

Reply

DrewM

7 years, 3 months ago

I'm going to go out on a limb and suggest you are the only person on the entire planet who would hold up the 2011 Element as a positive example of how to externally route cables… there's a reason that bike went internal (shifting) for 2012 and took the rest of their bikes with it…

… definitely to each their own!

Reply

taprider

7 years, 3 months ago

shimano's front pull derailleur solves its biggest problem

Reply

taprider

7 years, 3 months ago

you can add another internal hater to the list

it was tried back in the 1980s and failed, great at first , but after a season in the mud fancy fixed internal routing like the current Santa Cruz became a real pain

internal is also crap for when you have to box your bike for travel, or are doing back-country stuff and have to repair things

I like Rockies 2011 frames with all hoses and cables routed together on top of the downtube, looks really cool like a base guitar

Reply

Cam McRae

7 years, 3 months ago

I like Jeff's artful solution. I used a different one on my 2015 Giant Reign, suggested by James Healey when he was working for Giant, when I had the same issue. It really did drive me crazy as well. The Reign has medium-sized openings that are just big enough for this fix.

The idea is to use coiled zip ties as suspension for the line to keep it from contacting the downtube. You just tighten a tie around the line, coil it up and feed it through the hole. I did this at four intervals to be absolutely sure. It makes it a little tricky to remove your line but not too bad and it works perfectly.

Reply

Vik Banerjee

7 years, 3 months ago

I ignored the stupid internal routing on my last bike and used stick on cable guides. Simple, easy and I can't get excited about seeing or hiding a few inches of housing on a bike from an aesthetic perspective. As I shop for a new frame I'm giving points to bikes with external routing.

Knolly gets props for providing both options for example.

Reply

DrewM

7 years, 3 months ago

I like that about Knolly. Linked to them under the last heading. Doing both is definitely an added cost mind you.

They don't make a slack, short travel, 29'er though… Come on Noel!

Reply

Vik Banerjee

7 years, 3 months ago

I'll pay a bit extra for that option.

A 29er is apparently in the works.

Reply

Rob Gretchen

7 years, 3 months ago

Good one… Andrew…. what I have done on a few frames is use a piece of pipe insulation positioned inside the down tube. All the cables route through the insulation and its absolutely silent. Costs pennies and weighs virtually nothing.

Reply

DrewM

7 years, 3 months ago

Good idea Rob. Does it just work on frames with good size openings though (Rocky, Trek, …) or can get it into a frame like the Intense with small ports (and the cables in from there)?

The bigger the openings the more options it seems.

Reply

Rob Gretchen

7 years, 3 months ago

Yeah for sure… some frames are more adaptive to this technique… I find you can often insert the insulation through the headtube if the ports on the frame itself aren't large enough… it takes a bit of finesse to get everything together, but that bit of extra time translates to a quiet ride… even on our Pivots we use it… their cable management system is excellent, but we still got some cable rattle occasionally.

Reply

DrewM

7 years, 3 months ago

Jeff, with his dual focus on training mechanics and teaching shop profitability, would smile broadly and say something about the potential service revenue from internal routing (he's damn fast at swapping cables & solving noises - practice) provided you charge properly for time and experience.

I on the other hand will flip 'the industry' the bird while holding up a bag of zip ties.

Reply

Rob Gretchen

7 years, 3 months ago

Yeah…. I get it…. the cool thing is as a mechanic once you've done a handful of them it gets easier and easier… but I prefer external routing personally…

Reply

Please log in to leave a comment.