Interview

Developing the Chromag Dagga Pedal

In recent years flat pedal riders have seen a growing number of options to choose from. And during that time, each release has presented footloose aficionados with a quality option worth considering. But there have been some parallels to what we've seen with updated bike models. They’re not exactly getting slacker, and in many cases aren't getting lower, but they are getting bigger.

Chromag released their latest pedal in the latter half of 2019. They partnered with legendary downhill racer and flat pedal assassin Chris Kovarik on the new design, which dwarfs other Chromag pedals. In terms of the overall footprint, I believe the 120 x 115mm platform is the largest available. But as I discovered, the Dagga pedal isn’t Chromag racing to produce the biggest pedal; the size came from the design process with Kovarik, spurred on by some interesting spacing choices by the legend himself. How few pedal axle threads are you comfortable running in the crank? Yikes.

Kovarik required large and aggressive pins, and the platform shape disguises a dagger. The process saw engineer, Ben Arnott, dive deep into axle configurations and bushing materials too. The result is one of the most aggressive looking flat pedals on the market today – perfectly suited for the likes of the Karver himself.

I recently sat down with Chromag founder and designer, Ian Ritz and engineer Ben Arnott to discuss the new pedal. Unfortunately, Chris wasn’t available when we met but I discussed a few other elements with him afterward. I also have a set of Dagga’s ready for review. Stay tuned for that.

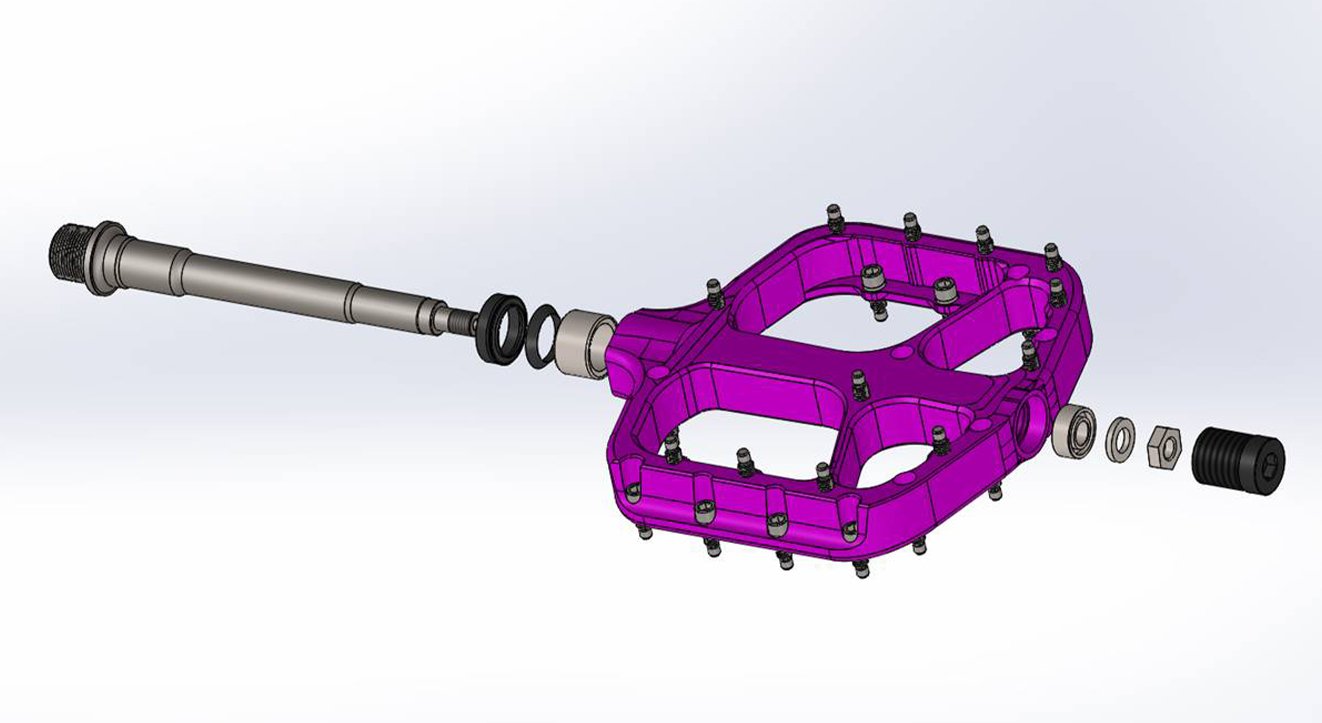

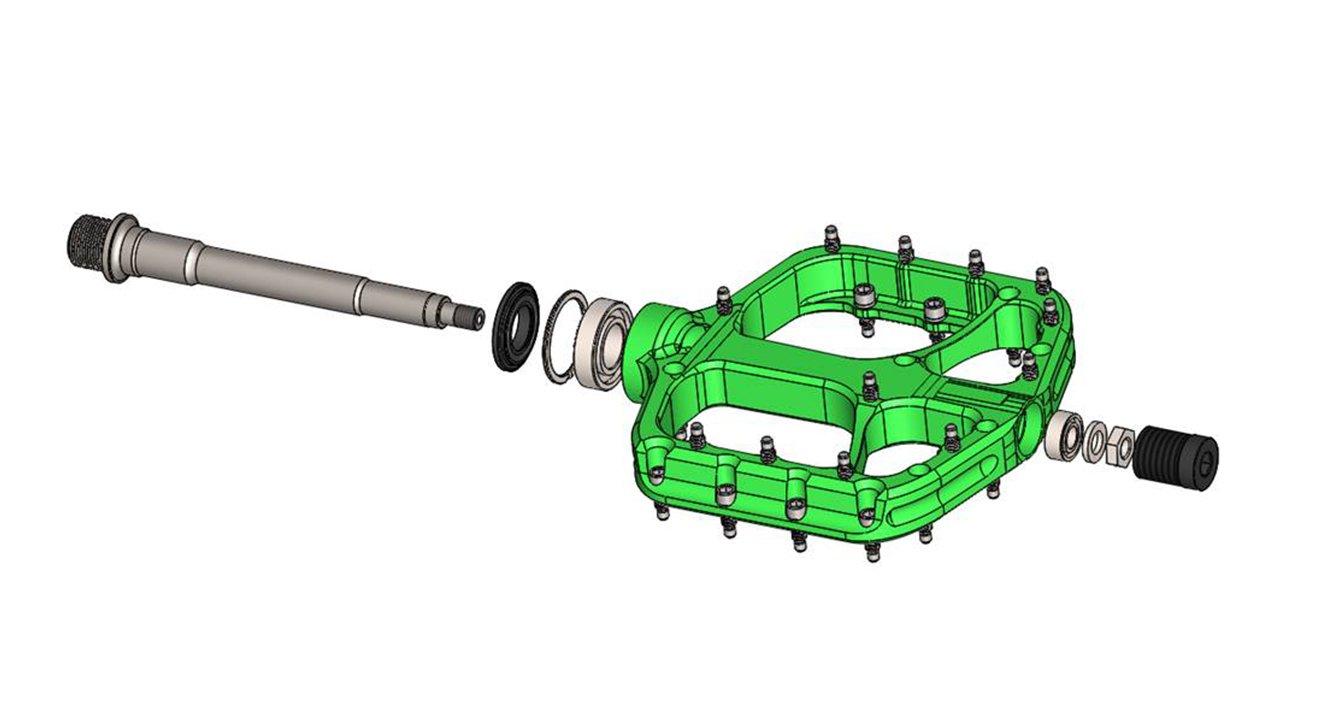

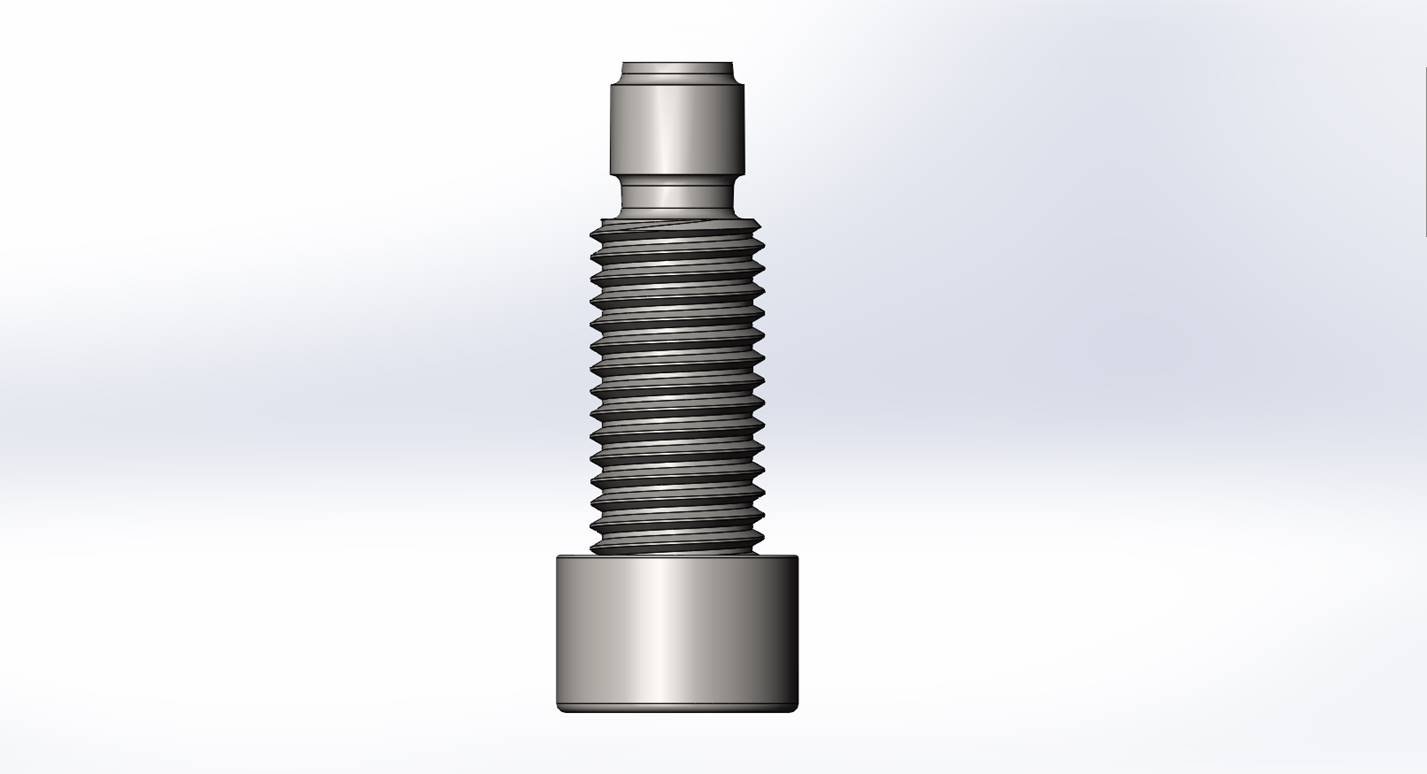

A prototype CNC'ed variation of Kovarik's signature Dagga pedal.

Chris Kovarik Comments on His Dagga Pedals

Ben mentioned he’s noticed you roll your feet side to side on the pedal when steering the bike. Is that a conscious habit or is it something you naturally do?

It's something I naturally do, it helps me steer and push the bike in different directions.

How much did this habit influence your search for the ultimate pedal?

It helped a little I guess, the Dagga has nice rounded CNC machined edges which could help your foot roll off the side of the pedal for this technique I use.

What exactly were you looking to achieve from the pedal design?

There were a couple things I was trying to achieve with the Dagga; Pin height with washers for adjustability so I have a grip option for trail or DH riding, Ben Arnott helped a lot with this. Platform size as I use a bigger DH specific shoe. The look of the pedal had to suit my style and technique of riding and I think we nailed it. Durability is a key too, the Dagga is shaped to look and work efficiently but is also meticulously designed and shaped by Ben Arnott and [Chromag] owner Ian Ritz for strength on impacts such as hitting your pedal on rocks etc.

Previous to the Dagga, what flat pedals were you riding?

I was riding a local brand back in Brisbane, Australia – a pedal called Chunked, designed and made by Simon Krelle. Simon hooked me up for about 3 years. Part of my idea on width for the Dagga actually came from the Chunked pedal.

What was the biggest challenge in developing the pedal for you?

Everything, it was the first time I'd had the opportunity to work on anything that was going to have my name on it so I wanted the Dagga to be right the first time around, I guess that's why it was a 2 year-long process. Ian Ritz spent a lot of time behind the computer drawing up images we both could agree on, the time put into every detail blows my mind. I had the name of the pedal already laid in place before it was made, I wanted it to be the Dagger which went with my nickname the Karver but also had to shine on the pedal. I sketched up some drawings and I wanted the Dagger to be shaped into the CNC design of the pedal where the axle runs, but due to strength issues, we had to flip it and run the image the other way which I think worked even better. Also, my wife Claire (Chromag designer) added her touch to the name of the pedal and decided it should be called the Dagga which is like our Aussie slang.

What are you most impressed by with the new pedals?

The whole pedal, I love how it's machined, its a piece of artwork. I'm stoked!

Chris wanted tall pins for grip but he also wanted their height to be adjustable. As they discovered during the pedal's development, all tall pins don't equate to increased grip.

Interview with Ian Ritz and Ben Arnott

A.J.: The Scarab pedal was released in 2013?

Ian: Sounds about right.

Was that released as the gravity/freeride flat pedal?

Ian: Yeah, yeah. I would say definitely, that would have been the focus. It's funny, I'm just trying to remember, you know, all the kind of intentions that went into it. I know at the time we were talking to a lot of people that rode in the bike park for feedback and one of the main intentions was to make it a big platform – bigger than most of what was out there. So in that respect alone, I would say it was more gravity pedal, gravity focused pedal.

And then a year later the Contact was released. Um, that was a sort of tighter Q-factor, smaller platform…?

Ian: Yeah, and that was really driven by Brandon Semenuk too. He wanted a pedal. He had tried the Scarab and he liked it, but he wanted a pedal that was tailored a little more to slopestyle riding and an in-bound stance – so placing the foot closer to the crank, really.

So now we're on the Dagga. How does that fit into the range?

Ian: Yeah, well it's, the next evolution in size for sure. I think, you know, it's obviously the biggest pedal we've made and I think it rivals pretty much anything out there for size, especially… Well, both in terms of width – Chris wanted a really wide Q-factor. He wanted to stand wide on his pedals. But we made it a long pedal also, just to dissipate pressure and have a lot more contact on the feet.

So you say that Chris wanted a wider pedal. Is that how the idea started?

Ian: Pretty much. Uh, Chris was doing a bunch of funny things… You know, we ride a bit with Chris because of Claire who works here, primarily, and so he was telling us a bunch of stories about different things he tried to do with pedals to get them wider; like stacking half a dozen pedal washers under his… just going, you know, for the minimum number of threads he thought he could get away with just to stand a bit wider. And then we also did a ride with him where he had these DX clipless pedals and he'd gotten a friend to manufacture the axles with an extra 15 millimetres of length on them just so he could stand wider. And he gave me those pedals to ride and I couldn't believe the difference it made standing wider. You know, on a clipless pedal in a very fixed position there's a very clear difference when you're standing wider. So that was one of the key things he wanted, was just a pedal that would widen his stance to have more power in cornering and, just riding in general.

Yeah. More stable hey…?

Ben: Also if you ride with Chris, he has a… I've never seen really anybody else do it before, but we chatted with him quite a bit about it with regard to clipless pedals and flat pedals, but he tends to roll his foot side to side on the pedal when he goes into a section, say it's like a – I don't want to speak for him and say how he does it – but if he's coming into say a tight left-hand, steep section, he'll roll that left foot left on the pedal. So he's still on the pedal but he's rolling it. Like, kind of pivoting it on the pedal.

As the bike is banking that way too?

Ben: Yeah, I guess so. So I don't, as I say, I don't want to speak for him. You know, I asked him about it when I saw him doing it. He also mentioned that to us as an idea for a clipless pedal – to have like, some float in that direction 'cause no pedals have that really. They're all pivoting about the ball of your foot. And he was talking about pivoting it kind of along with your legs axis if you like. So I think he likes the wide platform to help with that as well.

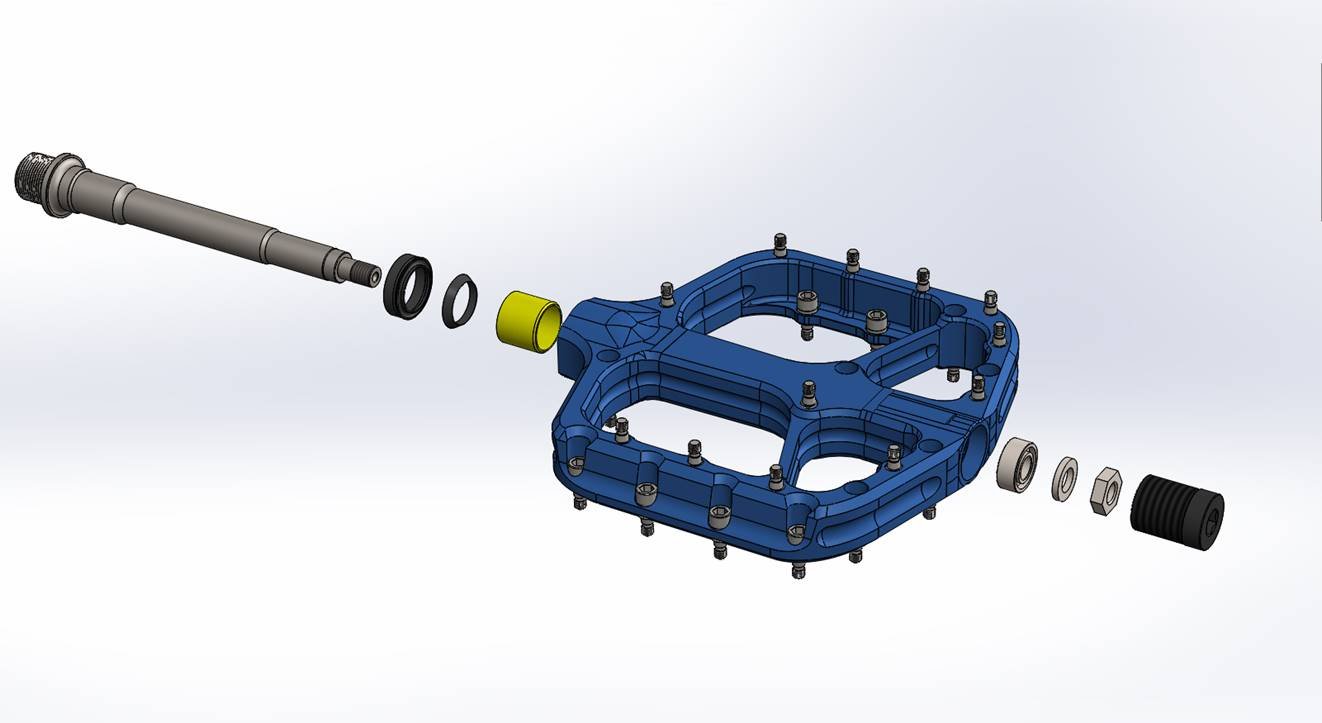

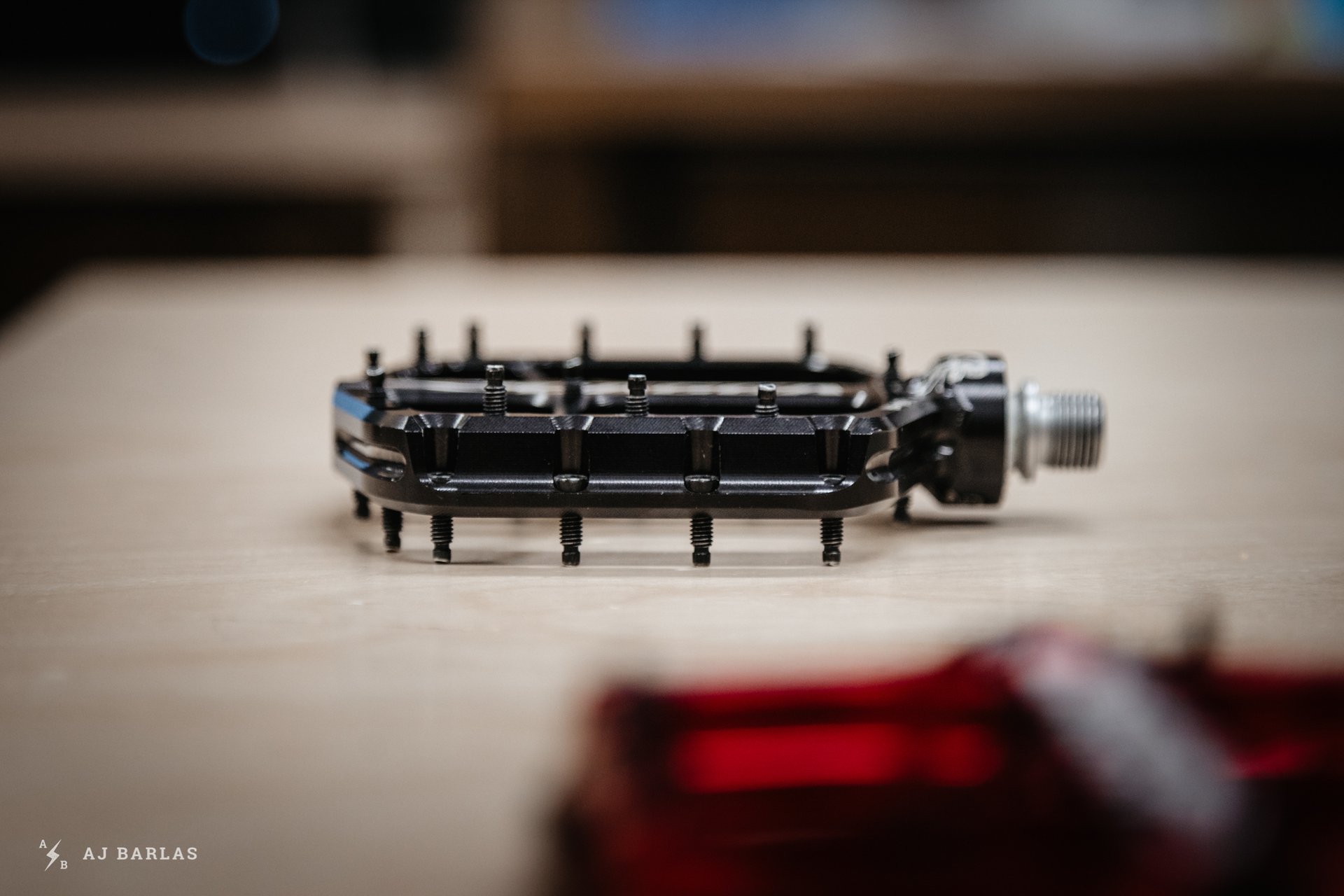

The pins are long, even with the stock washers in place, but they can be adjusted to suit preferences. Kovarik runs them shorter on his trail bike than on his DH bike.

It gives him the space to do that and still be on it. 'Cause I guess before they got that wide… you roll your foot, you're rolling off the side of the pedal.

Ben: Exactly, yeah. So I think he was riding right on the edge of all the flat pedals that he had and that. So he wanted something that allowed him to be able to do that sort of thing but be well within the edge of the pedal and such.

Yeah right…

And I think… we've chatted about it a lot but Q-factor of pedals is something that's really under, been kinda under-investigated in the mountain bike industry. A lot of it comes from road cycling where you want as narrow Q-factor as possible to avoid the chances of you striking your pedals as you corner and pedal.

If you look at road bike cranks, for example, they're always touting how tight their Q-factor is and it's a real big thing. And also for aero on time-trial bikes or whatever. So mountain bikes, it's another one of those issues which are never a problem.

And so I think it's something that, you know, we've talked about a lot and maybe more related to your hip width than anything else.

Ian: Yeah, yeah.

Ben: If you have naturally wider hips, you're probably gonna be more comfortable with your legs in a straight line, down to your pedals rather than being in or out, as such.

That's not researched yet so we need to delve into what's working for who and…

Ben: Yeah, Ian has got the… he's got extensions, like steel extensions on his DX pedals. And I tried the pedals that Chris had, with the longer axle. And for me they were… I could tell they were too wide, just because it felt like my legs were kind of splayed out. But then I've ridden something in between as well and felt that was more comfortable. So I think there's… it's like saddle width or, you know, there's things that….

Yeah, everyone's ergonomics are different…

Ian: It does relate a lot to body type. Like, I'm on plus 20-mil extenders on my pedals, which is quite profound when you think about how wide the Q-factor gets with plus 20 on each side. If you look at a fat bike crank, uh, I think it's like, less than 15 millimetres wider per side. So just the result of those extended on my regular crank, I've got a wider stance than a typical fat bike crank. And for me it's… I definitely noticed a huge difference in terms of control and stability descending and riding technical trail. But I prefer it when I'm pedalling too. The longer the distance, the better it is for me. And I've got, um, ageing hips, haha, so… And I'm kind of duck-footed as it is, so my knees kinda want to go out, but I know it's not for everyone. I know some people are very concerned about having a narrow Q-factor and so the orientation of their, hips and knees requires that.

The Chromag Dagga pedals feature a large 120mm x 115mm platform, providing the opportunity to stand with a wider stance – effectively Q-Factor – than other pedals.

So does that work into how this pedal really fits into the line is now you've got three different, quite different, Q-factors in your pedal range, hey?

Ian: Yeah. Well, I suppose, I mean in a way we're kind of entering into two different areas because a bigger pedal, in general, does suit freeriding in a lot of ways. Um, because you're cornering, you're taking a lot of impacts and having a wider stance is probably a more natural body position to deal with that. It's kinda like, you know, I would liken it to skiing or snowboarding where you're, you know, you would widen out to deal with more chop when you're skiing or carve a harder turn. And I think you can really notice that when you stand wider on a bike, like going into a rough corner, that's also dropping away in vertical. You can articulate the bike well and you can have a lot of power in your body position standing wider. But obviously there are some potential negatives like striking pedals on things and then when you're just sitting and pedalling for a long period of time, you want the best setup for your body as well.

Ben: We're always talking about different… like boost standards and you know now super-boost plus is something that we've chatted back and forth about with regard to new frames. And it's funny because looking at the press releases about super-boost plus in particular, one is that you get all the advantages of the 157 rear hub, like wider stance for that hub and effectively a stronger wheel, but you get to keep the Q-factor of a 73-millimetre long bracket. And so, you know, we're kind of reading that and thinking but, is that even a good thing on a mountain bike? Would it not be… maybe, you know, an 83-millimetre bottom bracket would be pretty good for a lot of people and it would give us a lot more space to get chainstays in there and all these sorts of things. So yeah, it's definitely… A lot of the industry is focused on a narrow Q-factor but people are, as time goes on more and more discovering, as we have, the advantages of widening it out or even just fitting it to you.

That's cool. Mountain bikes are definitely changing in the sense that we're, at least over the last few years, it feels like we're really starting to step into our own shapes and everything….

Ben: Yep. And yeah, if you ride a motorcycle as well, like a motocross bike or trials bike, your feet are way wider than they are on a mountain bike and you feel that. It feels secure standing there and as Ian said if you were to drop off something on that you'll feel more comfortable than I think you would wish you were narrower together.

Once you determined that you're going to go down this route and make a new pedal, what was next? Did you test competitors'? Did you get straight into mock-ups – I mean sketching probably comes in there…

Ian: We did a bunch of hand sketches and Chris… he basically laid out the best examples of what he had to date and then we just started drawing from there. I think we did like five or six versions, but, it's basically a matter of trying to fit the layout with what Chris was asking for and at the same time, you know, work with placing all the hardware and traction pins; everything that has to fit in that space as well. So Chris wanted other things other than just size. He wanted a more aggressive traction surface – he wanted a pin layout and a pin type that would bite the shoe better. So we were, you know, everything has to fit and within the space that you're working with. So yeah, with a bigger platform, you know, we wanted it to be well supported. So there were some uh, what would you call it, bracing arms built into the design – we had a few different versions. But yeah, you know, when you're designing something, you often kind of work with everything that has to be there and then you keep shaping it and what we landed on is what we have.

That kind of goes into the next question. How did you pin down what to include, test, and what to not even worry about? Or did you literally throw everything at the wall and then as you say, you have to remove things here and there to….

Ben: Well we usually start with a kind of, set limits, which are the design goals, you know, and there are certain things which we would really like it to have, things that would be good to have and so on and you kind of prioritize things and as Ian says, that's how you end up with this design at the end, which kind of ticks as many of the boxes as you can. And, with a pedal especially, there are so many factors that you have to take into account to get it to, you know… A prime example is that Chris wanted the pedal to be concave and that's a pretty common thing that you hear from a lot of people – that's what they want a flat pedal to be like. But in order to make it concave, the center of the pedal, which is where the axle goes, has to be the thinnest part of the pedal. So then you have to think you've got to get an axle in there and bearings and bushings and… So, I think over time you're basically kind of… it's not compromise but you're just kind of like, you're working within those limits and trying to make it as good as it can be while still fulfilling all the things that you wanted to.

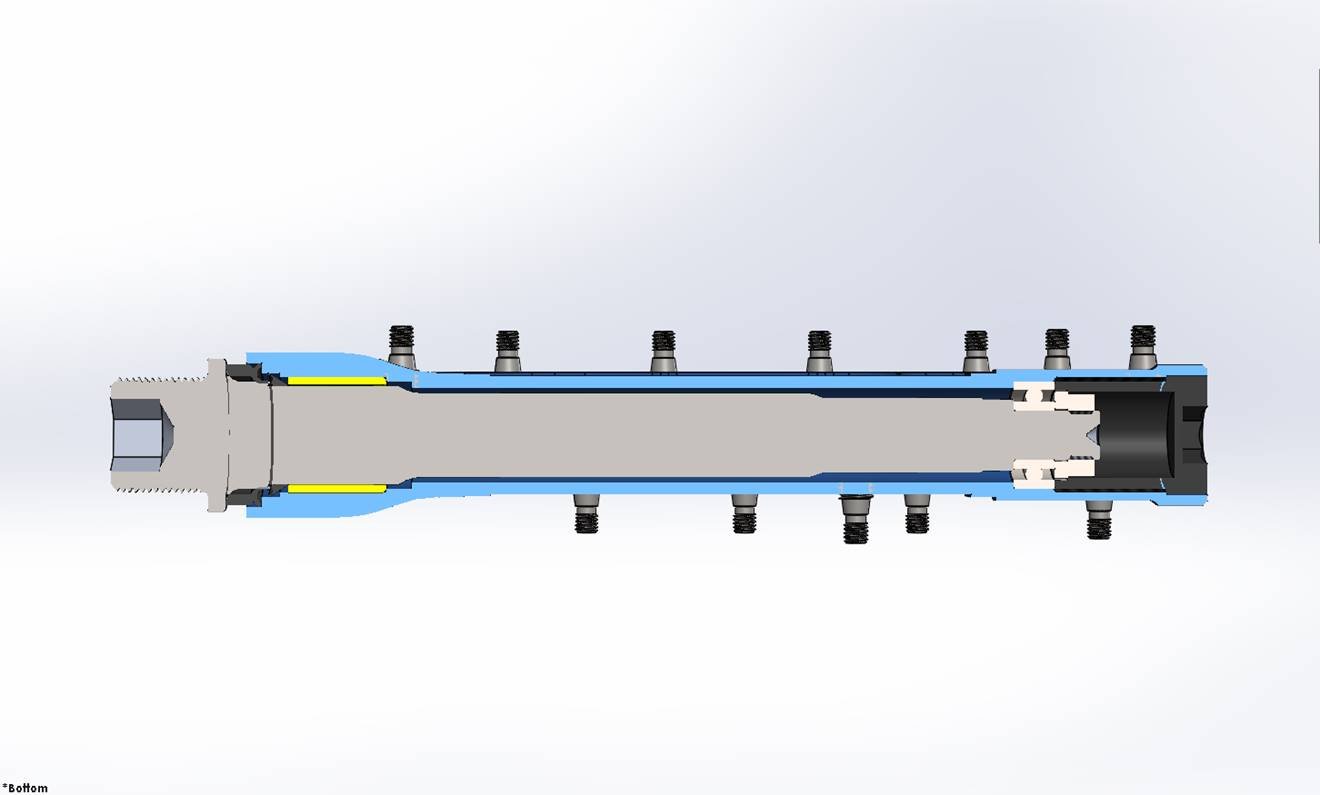

A cutaway of the pedal shows the different elements of the axle system. Two seals at the crank end (left) keep dirt and moisture out, the DU bushing sits directly after the second seal, before the axle narrows, spanning across to the end where the cartridge bearing rests next to the securing nut, closed in by the end cap.

How did it go as far as from the computer to standing on a pedal? Did you guys do a bunch of additive material tests or…?

Ben: So with the pedal, once we had the kind of rough shape drawn out and pin locations, for example, we were regularly going back and forth with Chris and showing him. Every time we made anything remotely a major change to it, Chris would come in and have a look and kind of give us his feedback. We got to a point where we were pretty happy with the actual shape of the body. And then we were looking into the different ways we could lay out the bearings in the pedal.

Right.

Ben: And currently all of our pedals have, uh, DU style bushings at the crank end and then a small cartridge bearing at the other end. And that setup actually works really, really well in a pedal and we're very happy with it in general. But there was a good opportunity to have a look at different ways to do it. So I made three versions of the pedal, one which was using exactly the same setup as the Contact to the Scarab, one which had a needle bearing where the bushing normally is and one which had a bigger cartridge bearing, like a bulge in the pedal body where the bushing normally is.

So we had those three options and this was kinda, you know, the only question I had for Chris regarding this was how would you feel about a bulge in the pedal on the cartridge bearing one. Which he kind of said he didn't think it was going to be an issue. So…

Ian: There was also the aspect of how the pedal would free spin because we were able to get a lighter spinning pedal with at least one of the bearing configurations.

Ben: And that's almost like a personal preference thing we've found after speaking to a lot of people because some people want their pedals to spin as freely as possible and some people want them to….

Be locked…

Ben: Yeah, spin a bit slower. And so certain things like that when you're designing these sorts of things, at a certain point you have to kind of take people's feedback but then just keep moving on because there are so many different opinions.

So at that stage, we had some 3D printed of the different types.

Chromag tried a needle bearing at the crank side of the axle, in place of a bushing. They found it posed durability issues and cost more.

Another option tested was a cartridge bearing at the crank side of the axle. This creates a bulge at the end of the pedal and while some have a problem with this, Kovarik didn't have a problem with it.

In the end they found their current method of a small cartridge bearing at the outer end and a bushing on the crank side of the axle to be the better solution. They favoured its durability, value, and function of this setup.

So the layout options you were doing were conceptual, on the computer in your renderings?

Ian & Ben: Yeah.

Ben: Yeah, and then, there comes a certain point in any design where you think I could actually make, it would be worthwhile to make a model of this, like a physical model of this, by printing it or machining it, or whatever.

Ben: So we printed a few of them. It's a good thing to do 'cause we actually can fit all the parts of the axle and bearings that we already have and actually see if it goes together and how it looks and everything and put pins into it. And those pedals you can put on a bike and ride around the parking lot here carefully, but you can't drop off a curb on them cause they'll probably break.

Yeah.

Ben: But it was a really good way to feel the traction of the pedal, which was instantly on this pedal – as soon as we put the 3D printed one on the bike, you could really feel how much traction there was. So that was definitely a useful thing to do. And the next stage, I'm trying to remember, but we….

Ian: We did three different rideable prototypes after that – alloy, they were all alloy.

Ben: So we did that with the three different bearing setups.

Yeah right?

Ben: Which is, you know, normally we would just get the one that we were thinking we were gonna actually make but with the vendor we're working with, it was easy enough to get them to make one set or two sets of each, I think. And so yeah, we had them here and we sent some with Chris obviously and sent some out to other riders that we use and had people riding them….

And get all the feedback and move ahead….

Ben: Exactly, yeah. I think we discussed it a lot but it's pretty obvious that the bushing setup – the existing setup that we were using was going to be the one we went for.

There were enough people that said the bulge of the cartridge bearing one annoyed them enough that, you know, it didn't seem ideal. And it was going to be more expensive because the bearing was more expensive. And it was going to require a new seal which is added complication to fit over that size of bearing. The needle bearing one worked fine. It was not really any noticeable difference between that and the bushing version, but the needle bearing was more expensive and more difficult to remove. So it was a really good experiment to kind of see how that sort of stuff would work.

The black pedal was Chromag's first 3D printed sample. It used the same axle system as their current line of pedals, which they ended up staying with. The orange pedal is their second 3D print and used the dual cartridge bearing axle option they were considering.

And really good for you guys to be testing it but also kind of humbling to be like, oh, we're using the best one anyway.

Ian: It was interesting. I'd wanted to try a needle bearing for a long time but because the needle bearing is generally an open assembly, it's probably the most susceptible to water and they would corrode quite easily. So just in terms of long term serviceability, they were not the best option and they were the most expensive option as well. So not really a whole lot of benefit from them.

More cost, less durability, that's an issue for people.

Ian: Yeah.

Ben: We also did, I should say a bunch of different bushing testing during the development of this pedal. I spoke to a couple of different vendors and you know… If you ever look into when you want to buy a bushing of any size, there's maybe… from each vendor, there are at least 50 different materials you can get. And they all have, uh, like selling points and you know what they're meant to be good at and not so good at. And so if you narrow that down, you can instantly get rid of 40 of them. And then you have these 10 which on paper they all look like they're going to be brilliant. So we ordered samples of each one of those which were potentials and then put them into a bunch of different paddles… Because it was the same size we could put them into our Scarabs and Contacts. So we had people around here riding on them and we were putting them in dry, some of them in greased and so forth.

Then after a couple of months, we ended up with these pedals coming back in and I would inspect them and measure them and kind of, we got to the point where we were happy with this bushing that we were gonna use for this. So that was quite interesting as well.

Did that end up being a different one from what was in the current one?

Ben: In fact, no. We actually ended up going with our current one because the wear was very similar to the best performing other one we tested but they're a lot cheaper.

Ian: By far the most important thing with bushings is keeping them clean and the sealing arrangement around them.

Ben: The bushings in the pedals and all the ones I was looking at, they're actually designed to be run dry, they're not designed to be lubricated with grease or anything. The grease is just forming a barrier to try and stop water getting in and dirt getting in, sort of thing.

Ben shows me one of the selection samples for bushings that they went through.

We kind of touched on it earlier, but it'd be good to get a bit more info on it. Were there any limitations or restrictions, that influenced the outline and the shape of the pedal?

Ian: Limitations? I mean, we were definitely concerned about creating a pedal that would be onerous for peripheral objects on the trail and stuff. We didn't want to make a pedal that people are going to be striking on stuff everywhere. And that's a big susceptibility of every pedal, repeated impacts or just big impacts, you know, that can be really hard on the pedal itself, on the axle. You know, pedals generally are oriented one way or the other, 180 degrees opposite. So if you hit something while you're standing on the pedal, the next time you hit it, chances of you standing exactly the same way are really good. So what that means is that every time you strike your pedal, the axle is having an impact in a very specific orientation. And it's this, it's probably the same or the same in two different places every time and those strikes can be quite hard. That means that you have the potential to break an axle the more times you strike it because you're basically fatiguing it in exactly the same way each time. So making a pedal bigger and more robust was a concern just for that reason alone.

Was there ever a desire, I guess from Chris to go even wider than you did, or is this kind of fitting in exactly to where…

Ian: If he wants them to be wider, he hasn't made that clear to us yet.

So you're able to achieve the width that you were setting out to do and…

Ian: Yeah, I think what we've produced for Chris was something that he never had before. So he's been quite grateful, for what it is. You know, with so many things like this, you make something longer or bigger… You know, standards change and we're constantly realizing that the limits are more than we thought they ever were. But yeah, so far this is, this is a pretty big pedal, we're settled on where it is for the time being,

We should talk about the length a little too, hey. It's pretty interesting how… It's actually from what I can find online, it's like five to 10-mil longer than most pedals out there.

Ian: Yeah. Yeah.

But you guys didn't just do that for a big platform, there's talk of a better use of your foot over the pedal and the energy going through it and stuff like that.

Ben: Yeah, one of our guys that works here, Seb, he has knee issues and he has a pair of those flat pedals from, I can't remember which brand they are….

Ah, Pedalling Innovations.

Ian: Yuh.

Ben: And he just wouldn't stop singing their praises about the difference they've made to him and his experience pedalling. So that was in our minds…

Ian: It's something that we took to Chris and he hadn't even considered it. I don't know if you've seen Chris's calves, but they're like, they're like most people's thighs. So, Chris and… As a hardtail rider, I subscribe to this a lot; the idea of standing on the balls of your foot because you get all the suppleness by being able to have your ankle articulating. So initially I was, I kind of rejected the idea of, centering a pedal axle over your ankle, but we brought this up with Chris and he started to be more conscious of it while he was riding. And he did say that somebody who's riding downhill and freeride and in high impact scenarios could benefit more from being able to move their foot forward on the pedal so that you know, your ankle and your calf alone weren't taking the brunt of bigger impacts. So that was an intention in making the pedal longer as to give the rider more freedom to place the foot further forward on the pedal and still have good coverage on the shoe. Good traction.

Is there, I mean I haven't ridden them yet, but is there a benefit to the grip and traction with that length as well as the… I guess fatigue?

Ian: Perhaps? Like there is the theory that you know, too many pins would be kind of like a bed of nails where they're, you know, they don't have enough individual penetration because they're too clustered. So, perhaps spreading them out a little bit, but I'm just thinking on the fly. I don't know.

Yeah. Speaking of pins, I remember having a chat with Chris in the summer about the pedal and it was almost finished and he said there was a last-minute kind of change, with pins and stuff like that, that he was gonna test out. Where do the pins… I guess their placement normally comes when you're designing it on the screen. Is there ever a reason to change that once you get an actual design to stand on and test, and how do you decide how many and all that sort of stuff.

Ben: On the Dagga, for example, is really… In my very early sketch, with the shape of the pedal that you're envisioning, layout depends on there to see where they would go. At least physically see where they would fit. Kind of look at them and see how much sense it makes to have a pin there. If you look at the Dagga, for example, there's a pin that's at the end of the axle in the middle of the pedal. Personally, when I ride it, I feel that pin under my foot because it's right in the ball of my foot. So that's one that some people take out but I've also seen a lot of people running it. So, I guess we err on the side of a lot of pins and from there on it's kind of your choice to decide which ones to take out. That's a big selling point of the Scarab pedal is that it's got all the adjustability.

The Dagga pedal has 24 pins – 12 per side. Their height is adjustable via washers. The proto CNC pedal here has longer versions of the pin used in the Scarab and Contact, but it didn't work as desired in the longer length required for the Dagga.

That's what I was going to say; the Scarab pedal had insane adjustability for pin placement.

Ian: It did and a lot of that also was with the intention that you could damage a hole and just use the adjacent one as a way to keep your pedals going.

Ben: Yeah, I guess a lot of the early prototyping, like 3D prints, a lot of that was just real-world testing. I think it would have been pretty clear if there was a pin that was amiss, you know – it would feel out of place or if there wasn't enough and we were losing traction in some area. But from pretty early on I think the actual pin placement was pretty good and we were pretty happy with it. And from then on it was just refining the actual pin design and pin shape.

Ian: Yeah. At one point we had a really long pin – just a longer version of our original pin, in order to try and get more attraction out of the setup. I guess I'm jumping ahead, but we found in that case you tend to just hover above the pedal at a higher place. We got a bunch of feedback from some other riders that were testing stuff for us too, that we're looking for a little more bite and citing some other pedals that they felt were giving better traction. And that's how we kind of made our way to the current pin design, which is a threaded tip.

Are there any examples of unexpected elements that required changes to things like the pins throughout?

Ben: The pins was a good one because when we took our standard pin that works really well on the other pedals and just lengthened it – which kind of seemed like an obvious step for this more aggressive pedal. On those prototype pedals that I talked about earlier, we were seeing that a lot of the pins were getting bent really badly when they'd have an impact. It meant that they were… If they didn't damage the threads then it was really difficult to get them out of the pedal and it just didn't seem like an ideal… It was far from an ideal solution. So that's when like… I'm always getting mocked here for pedal pins 'cause I spent so much time looking at them and trying to draw different ones and really drive down into what's, what makes a good pedal pin or what makes them grippy.

A couple of things we talked about a lot was the material because we're trying to find a material for the pins that made them less ductile effectively, which means that instead of bending over, they would just snap.

Right.

Ben: So hopefully if you hit something really hard, they would just snap off. And, uh, so that comes from… The pins, sort of propensity to do that is from its material and its shape. So we looked at both of those things. Our pins use an M4 thread, which is relatively big compared to a lot of pedals around three and we kind of wanted to keep that 'cause it has its own advantages. But if you then just used a screw of that size, the actual pin is quite wide, probably too wide for most or from our feedback, from what most people thought. So, I'm jumping a lot of steps here but we eventually ended up with it tapering to an M3 thread. So the pin's actually got two threads on it. The M4 one threads into the pedal and secures it and then it tapers into an M3 thread at the top and there's actually a slightly thinner section where it goes from the M4 to the M3. The hope is that if you hit the pin on the underside that it'll break at that point, leaving you with just a little M4 stub in there that you can just unscrew.

That was a lot of different iterations to get to that but it's also quite a difficult thing to test 'cause they're actually really difficult to make cause they're quite complex for their size. You can't really CNC machine them, like on the lathe – you can, but it'll cost a lot of money and be hard to get good results. So it's a thing that requires us to commit to a design because we have to order a significant number of them. So, yeah that's definitely a bit different from some of the other things we make where we have to… We can do a lot more prototyping. By testing with M3 set screws in other pedals, you could tell that the tip of an M3 threaded thing is really grippy underfoot. So we were fairly confident in that design that it would work.

Did you end up changing the material in the end too?

Ben: We didn't.

[Chuckles]

I guess there's a slight chamfer where it does change?

Ben: Yeah exactly.

Ian: And even that was really hard to achieve to the extent of what Ben had drawn. Because you know, you're basically machining a hundred thousand screws on a Swiss machine. That's making a part that's three millimetres in diameter. So then to get another like, 0.25-millimetre depression exactly in the breakaway spot, you're getting… It's there but it wasn't executed as… with the detail we had hoped for. But in the end, I think even cost is a pretty significant issue here. Like getting the material that we actually wanted to have with a heat treatment that we wanted to have, it all adds up when you've got 42 pins per set of pedals.

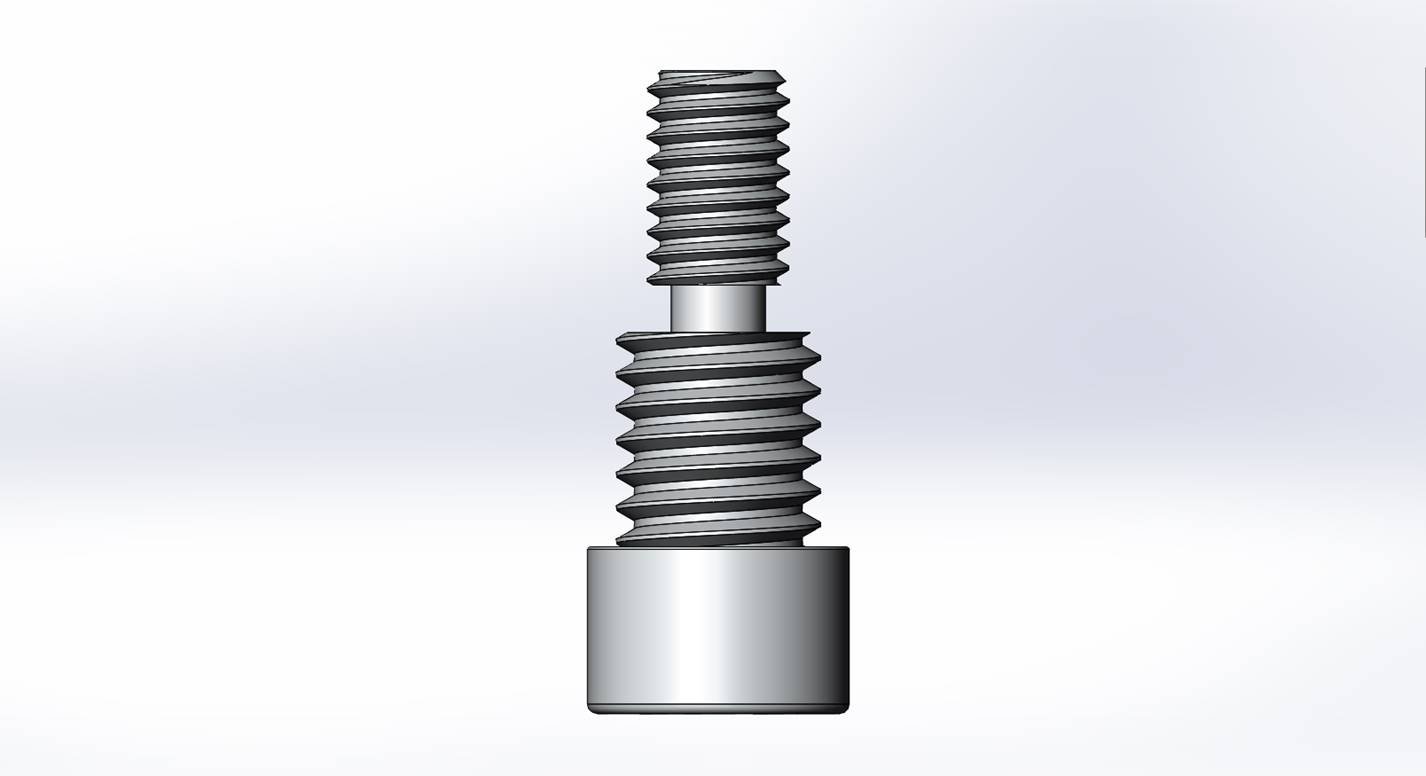

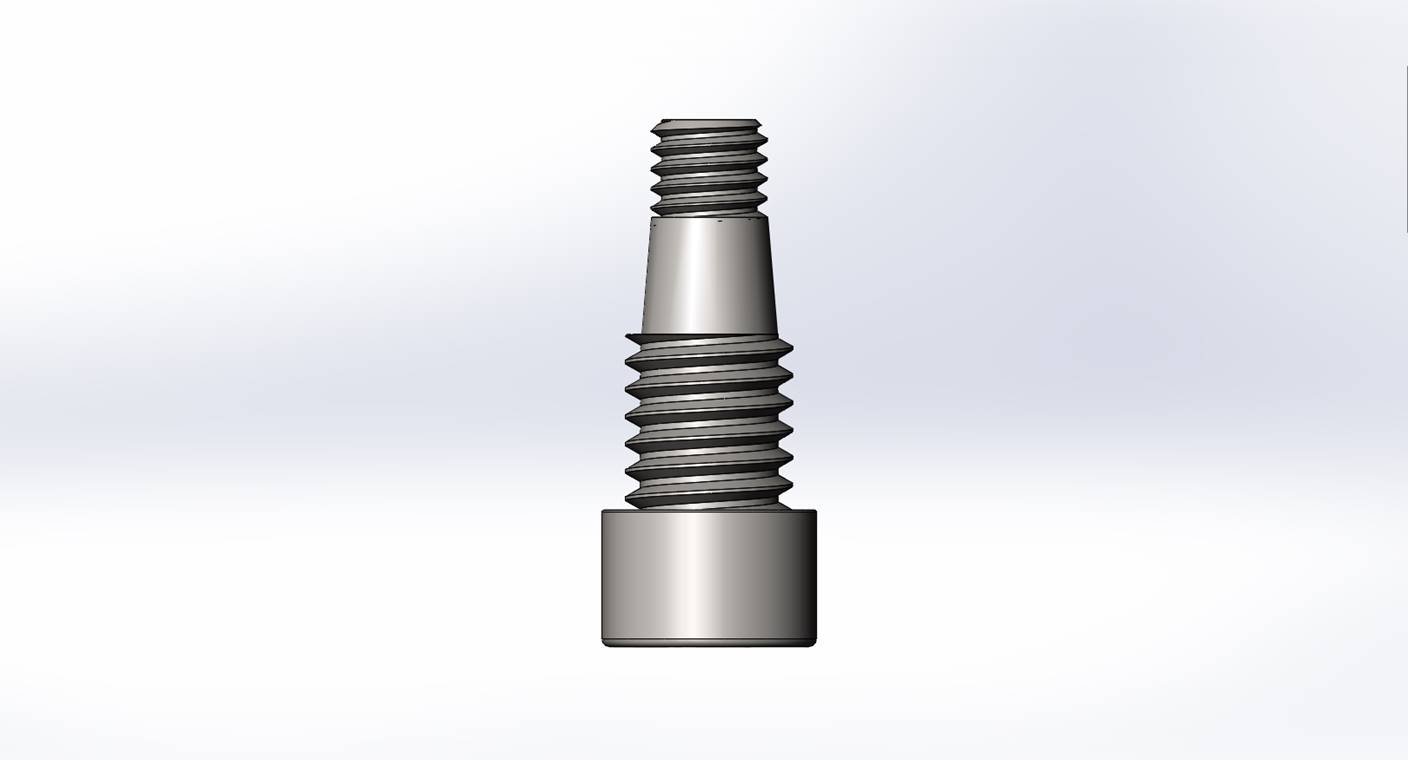

The original Chromag pin. They found at the length Kovarik was after for the Dagga pedal, this design didn't penetrate the shoe sole enough, causing it to feel like standing elevated, off the pedal.

Another option that Ben designed up. The narrower part in the middle was included to create a point for the pins to snap off when making contact with an obstacle. This would leave the M4 thread to remove cleanly.

The final design still tapers down from Chromag's preferred M4 thread for mounting the pins into the pedal, to an M3 thread. Chromag found the thread to help provide grip in the shoe.

And they're not a, I mean, you can't hide it, they're not a cheap pedal to begin with. So you try to…

Ian: They're not, and they could have easily been, you know, another 30% more than they are now by having things like a needle bearing or, yeah.

Ben: Well we also found… When we were pretty confident on that pin design, we got prototypes of them pretty early on and got a bunch of our test riders who were thinking about pedal pins, on them. The feedback was really, really good. And just from having a lot of those pedals out in the wild now, we're not seeing pedals come back with all of the pins bent over and everything. So I think we, yeah, it worked out pretty well in the end.

How long do you reckon it was between your initial concepts and having an option that you could test – even stand on it I guess, like the 3D prints?

Ian: I know from when we started drawing we probably were able to… we probably had a few prints going within a matter of months. The whole process from you know, concepts to actually having a production pedal was between one and a half and two years. Yeah.

And then what, people testing and actual alloy was like half that time?

Ian: I think we had our alloy samples by May the next year. So probably a year.

Ben: Yeah about a year.

Yeah right. There's some solid R&D on that.

Ian & Ben: Yeah.

The initial concept and everything you guys worked on a lot together, but it was your full-time thing for a while, wasn't it, Ben?

Ben: Yeah. I mean never… It would be full time for periods but we'd be doing other projects at a time. So it wasn't… it definitely wasn't two years of full-time work. But yeah, definitely a lot of time to get it right.

Let's talk about the platform and how you guys have that made. It's a forged then machined process. Why did you go to that? I think the only other options I've really seen are full CNC or extruded then machined.

Ben: Yeah, this pedal from the outset was meant to be our most aggressive pedal, our sort of most gravity oriented pedal, even though all of them are gravity oriented to a certain extent. With an extruded pedal you end up with gaps between the top and the bottom faces if you design them that way. Which is great because in general they're strong enough for most use and they're also a lot lighter than if you don't have those gaps effectively, but they are more susceptible than a solid pedal to an impact. Sort of crushing that in. So it seemed for this pedal that having that solid would be a good option from the start. So yeah, that's I guess kind of… we were drawing it like that from the start sort of thing.

Yeah.

And then when it comes to the forging side of things, like the first prototypes we had are full CNC'ed from a billet. After that, when you look at production and you talk about production numbers, it quickly becomes apparent that it's more efficient to forge them and then do minimal post-machining. So if you look at the Dagga, pretty much every face on it has had some sort of machining. But when it comes from a forged blank, there's a lot less to do. And the other big advantage with forging is that, the metal, the material is stronger for that shape because you heat it up and align all the grains into the shape of the pedal rather than CNC where they're random, they're not necessarily in the right direction. So there's a slight strength increase as well.

Ian: Yeah, a lot of it is… I guess it's a commitment because forging a pair of pedals – two separate forge moulds – is a huge cost commitment. So it's something that we go into with our fingers crossed that we can sell enough pedals to justify that. But also that we've got the design, you know, close enough to where we want it, that we can make that commitment as well. But it's much more efficient forging and there's a lot less wasted material when you do it that way as well.

While the Anvl aren't extruded (they're fully CNC'ed), the gaps between each face shown here are what Ben's discussing above. The DMR Vault pedal is an example of this (which I've also bent because of it).

The forging process translates to a solid platform between the top and bottom surfaces. This solid section makes for a stronger pedal, more capable of taking big hits.

With the size of the Dagga, you guys have moved pretty much to the front of the pack as far as overall platform size. Why do you think pedals are getting bigger? Like, you guys have your reasons for doing it, but everyone's coming out with a bigger platform pedal. Why do you think that is? Two-part question; Why do you think that is? And are they going to go bigger?

[Group Chuckle]

Ben: I think, uh, well people – modern bikes are allowing people to ride a lot faster. [You] Probably need your feet held onto the pedals better than you ever did before nowadays. Yeah, I guess, I mean I would say there's maybe been a bit of a resurgence in flat pedal riding. I feel like a couple of years ago when you go trail riding, everybody had clipless shoes and there'd be one odd one out with flat pedals but I'm seeing more and more now, people on flat pedals.

Ian: Yeah. I mean it may, it depends on footwear, if that changes a lot. This is pretty off-topic but this is the time of year when we start hearing from fat bikers and a lot of fat bikers are using Daggas now because they're running something that's like a boot.

Yeah right.

And uh, and so they like the traction and coverage. You know, we talked about those [Pedalling] Innovations pedals and they're longer than the Daggas are, I think that's an example right there that pedals can be bigger, at least one way. But you know, everything is connected, the design of the bike, what the rider's doing, the rider's shoes. So a lot of this, a lot of changes that happen in one place will affect a change somewhere else.

So it may depend on where bike design or drivetrain design or shoe design goes as well, or even trail and course design, you know and what riders do. If they're starting to do something different on their bikes that could affect it as well. But yeah, I don't know, it's… bikes are crazy that way because people are always experimenting and doing different things and when you think you've reached a limit, you discover years later that that was just a stepping stone along the way.

Ben: I think one thing with regard to the pedal platform size increasing is that people's feet or a finite size, and I think that's one good thing with the Dagga, that even people with massive feet, the pedal is still usually wider than their five tens or whatever shoe they're running.

Yeah.

And so I'm not sure the platforms will keep getting wider. I mean this could be one of those things where I have to come back and eat my words, but I think the Q-factor as we've talked about already, is something that'll probably burst on the scene at some point and like, Trek will make a bike with a large Q-factor and everyone will do it. Then everyone will be like, can't believe we didn't already do this, so I think if we're gonna go that way, then the way to do it isn't through pedals because you don't want to be hanging your weight farther out on this axle, which has got to be a finite size or a limited size, effectively. It'd be better to do that with your bottom bracket axle, which is a lot bigger, or your crank arms or your bracket shell or something. So that's… I think if we see any increase in Q-factor, as a standard thing, it's not gonna be through things like pedals, but frames.

More on the Chromag Dagga Pedals can be found on their site and we'll have a review ready in the spring. There's also some information on Q-factor available in their blog. Available for purchase at Chromag.com, dealers worldwide, or online at Jenson.

Age: 39

Height: 191cm/6’3"

Weight: 73kg/160lbs

Ape Index: 1.037

Inseam: 32”

Trail on Repeat: Changes as often as my mood.

Current Regular: Every test product spends time on Entrail

Comments

Perry Schebel

4 years, 3 months ago

those pins are terrifying.

Reply

Andy Eunson

4 years, 3 months ago

No guff eh. I was thinking those pedals ought to come with a couple units of blood just in case. But seriously pedals in different sizes, Q factor and such is such a good idea.

Reply

Timer

4 years, 3 months ago

Even more terrifying since knee+shin guards have gone out of fashion and everyone is just running kneepads. Does noone slip of pedals anymore or do people just accept the necessity of sacrificing blood to the trails-gods?

Reply

Kenny

4 years, 3 months ago

Sorry if I missed it in the article, but am I correct in assuming these new gnarly pins will also work in scarabs as well, since they kept the M4 threads?

Reply

AJ Barlas

4 years, 3 months ago

Hey Kenny. You are correct, the M4 thread and head of the new pins fit in the Scarab pedal. Chromag actually began testing the current pedal with the old pins, only in a longer version. They kept the M4 thread interface but changed to the narrower M3 thread to the tip, for grip.

They don't have these pins available on the site but if you drop them a line you may be able to get some.

I can't get images to upload here in the comments but you can check them below:

https://nsmb.com/photos/view/19844/

https://nsmb.com/photos/view/19843/

Reply

IslandLife

4 years, 3 months ago

On that note, was there talk of the new pins in a shorter version? Or are they the same height as the old pins when you use the washers?

Want the new threaded tips, but old height... hard to tell from the pics.

Thanks!

Reply

AJ Barlas

4 years, 3 months ago

I haven't heard anything about a new pin in a shorter version. The Dagga pin is longer, with the old pin stopping about halfway up the M3 threaded tip (see link below). You could perhaps try and source longer washers to shorten them more than the biggest washers included, but there's the issue with the amount of M4 thread securing the pin in the pedal body then.

I should also clarify that the red pedal in the images above is the only one in this feature with the new pins. They're also mounted with the shorter of the two washer sizes, making them more aggressive. I'm looking forward to seeing how much grip I have with these bad boys!

https://nsmb.com/photos/view/19845/

Reply

Kenny

4 years, 3 months ago

Thanks dude awesome pics. Yeah I'll ask chromag.

I have scarabs on one bike and vaults on the other.

I like them both but there's no denying DMRs pins with threaded ends are grippier. I prefer the more compact body of the scarabs though so this could be awesome. I actually have a spare set of scarabs so I could end up running them on all bikes with the gnarly pins.

Reply

Agleck7

4 years, 3 months ago

Glad to see some attention to Q-factor. I'm always riding on the outside edge/hanging off the side of my flats. Makes me curious to explore if there's a way to add a few mm to my Vaults...

Reply

Andrew Major

4 years, 3 months ago

I’m also very stance-curious, the Daggas are very high on my list of products I’d to try.

There are metal inserts (pedal threads into insert; insert threads into crank) available anywhere that does bike fit but I find they add too much of a difference.

It would be sweet to see more companies offering two axle lengths like Crankbrothers does for their clip-in pedals (I had a great experience running Eggbeaters with Mallet DH Axles) not in the Shimano XTR way of having regular and extra-narrow Q-factor options but rather a regular and wider option.

Another easy option would be to add a few threads so that it’s possible to run more than one, or maybe two, pedal washers between the pedal and crank without compromising insertion depth.

Very interesting stuff.

Reply

IslandLife

4 years, 3 months ago

After moving from fairly wide flats with a bit of a duck stance to clipless... I needed to go Crank Bros in order to get their wider axle kit... I even needed to use a washer on them to get my stance where I like it... though it still feels just a little restrictively narrow to me.

This article really spoke to me... after riding clips for a full year, I'm going back to flats. I am most definitely not at the level of Chris Kovarik, haha, but like him... it seems I like to move my feet around quite a bit and in ways that clipless pedals don't currently allow.

Even after a year on clips, I still find I just can't get as comfortable or be as confident, especially on gnarly terrain, as I am on flats. And I still find myself trying to move my feet and adjust their placement in different ways for different types of terrain, but feel held back by my clipless pedals fixed position.

I also like to climb in a different position than I descend... though I've kind of gotten used to climbing in a more mid foot position (I push my cleats all the way back on my Giro Chamber II's)... I love being able to move my foot back a bit for climbing with flats.

The only benefit I've found to being clipped in has been during races, when I want to get out of the saddle and just hammer/sprint... I worry less about my foot coming off and/or getting it back into the proper position for optimal "hammer time".

But, this seems negated by the times I come unclipped during a gnarly section or pedal strike, can't get clipped back in while still trying to be fast in that section, but am bouncing around on a slippery clipless pedal, forcing me to slow down... at least with flats, if my foot got bounced, I could jam it back on... and even if it wasn't in an optimal position, it was solid enough to keep pushing hard and adjust later when the gnar dies down. After a year of riding and racing, I still never got very good at re-cliping during intense scenarios.

Anyway, didn't mean for this to turn into a "flats vs clipless" rant... but I think there's a lot to be gained from wider q-factors and platforms. And maybe it even seems, bottom brackets? And I'm not a big guy... 5'11" with size 9.5 feet... maybe my hips are wider?? Not sure... maybe the width preference comes from years of snowboarding? Come to think of it, after the winter season... the first time I throw a leg over my bike, it always feels a little narrower than I remembered...

I get the sense maybe people aren't moving their feet enough?? Maybe I move mine too much? Maybe it's just how I learned to ride... I don't know.

Reply

AJ Barlas

4 years, 3 months ago

I agree with a number of the points you and Andrew raise. The wider stance available will be interesting, even if only a few mill wider than my current go to pedals. But I personally find the footwear to influence it. When riding in shoes that are narrower overall, I find my foot in between key pins but with my FiveTen Impact pros, they feel great. That’s what Chris runs too so it should make for a good comparison to begin with.

I also struggled with clips and while I got used to them to the point that I couldn’t remember the issues, I was instantly reminded when putting flats back on after 2 years clipped in. That was 3 years ago, now. If I raced, I could see trying them again, but I don’t and find flats more enjoyable. Each to their own.

Reply

[user profile deleted]

4 years, 3 months ago

This comment has been removed.

AJ Barlas

4 years, 3 months ago

Agleck7, You could try adding a couple of pedal washers like Kovarik was doing before. 😬

Reply

Agleck7

4 years, 3 months ago

🤔🤔😳

Reply

Jitensha Kun

4 years, 3 months ago

I moved off my Scarabs to clips because I was tired of my duck stance pushing my feet to the outside of the pedals as my size tried to find a wider stance. That these pedals are designed wider (and longer) is very interesting. I'm definitely intrigued and may have to give them a try.

Reply

LAT

4 years, 3 months ago

It’s good to see companies offering alternatives to the norm. I fitted a pair of large CB Stamp pedals to accommodate my wayward feet. The first flat pedals I’ve felt confident using because the platform is actually under my feet.

The new Shimano LX and XT cranks are available with wide q-factor, but the chain line moves out with it. I’ve been in touch with a couple of chainring manufacturers, but neither had plans to produce rings that would compensate for this. I’m hoping that they reconsider.

Reply

RNAYEL

4 years, 3 months ago

The lack of mention or discussion about the rumored Chromag full suspension frame in this article is an opportunity missed.

Reply

Please log in to leave a comment.