FIRST IMPRESSIONS | TEARDOWN

Crankbrothers Highline 11 Carbon Dropper Post

Carbon... what?

On the surface the new Highline 11 dropper post bypasses all my ideas on min-maxing, taunts my casual derision of weight weenies, and blows by my admitted lust for luxury. But please, allow me to explain before fetching the guillotine. In my defence, I will reference my well-documented weakness for titanium. The Highline 11 comes with sexy gold-titanium hardware.

Also, it has a carbon fiber shaft.

A carbon fiber what? That's what I said too. This is my very first opportunity to experience a carbon sliding surface, on any product. I asked a few industry friends who work in suspension, and dropper posts, if they thought carbon fiber fork stanchions, shock bodies, and dropper post shafts were in the future and they all laughed at me. Not nice sharing-a-laugh laughs. Not coy, 'yes that's something we're working on' laughs. I might as well have been Zoolander asking them which hammer to use for extracting files from the computer.

Here we are, it's April 7th, 2022 and in various places on the internet you can read about this new Highline 11 dropper post. I can't think of a product I've been more interested in reading other peoples' thoughts on. Is this just a luxury version of Crankbrothers' Highline platform? Does it introduce opportunities for stronger shafts for the massive lengths that dropper posts are hitting? Are we on the cyclical cusp of another fresh wave of weight weenie-ism that will see products like this contributing to sub-30lb Enduro bikes? If that's the case what other carbon products should we expect to see?

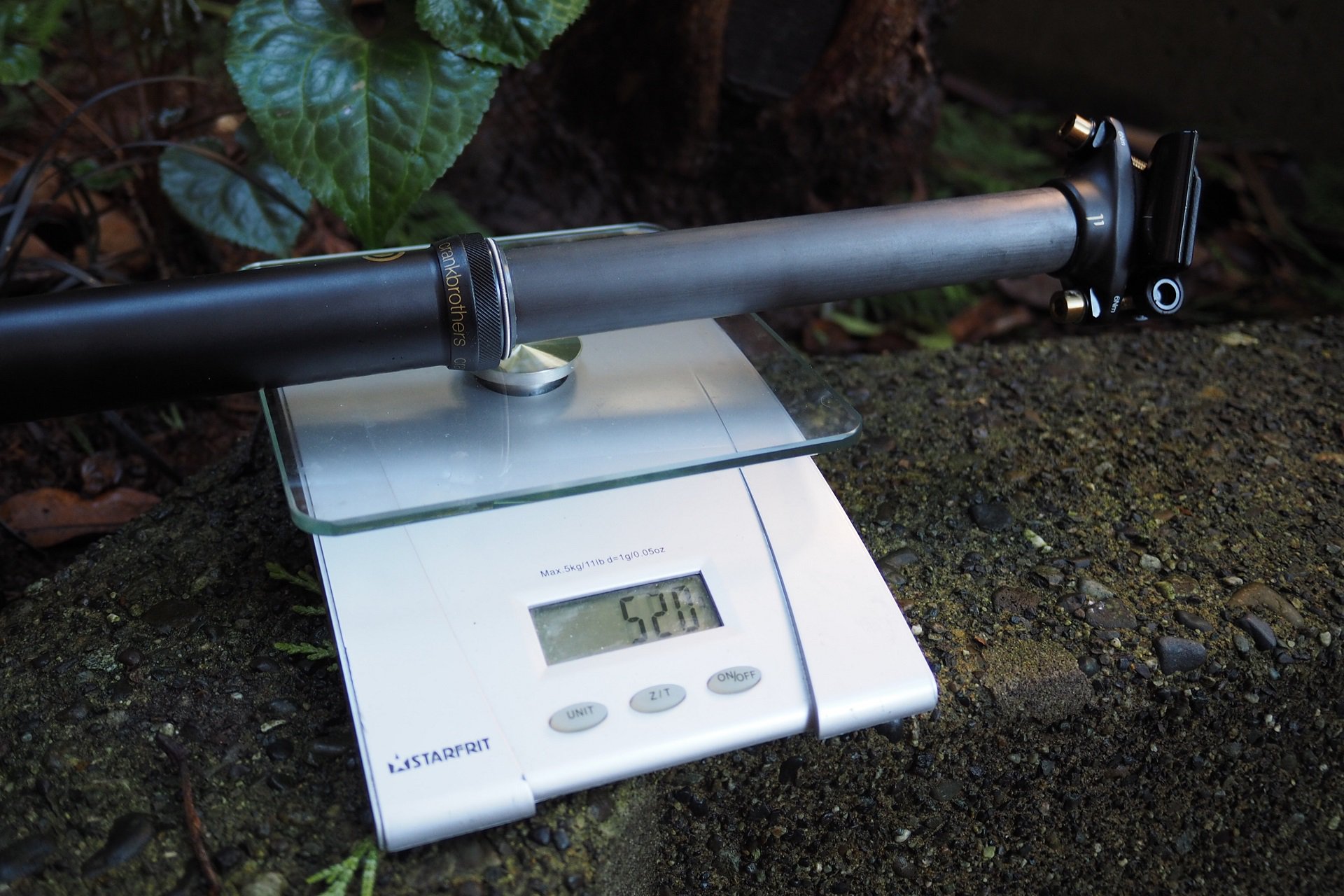

The shaft is carbon. The hardware is Titanium.

It's 84-grams lighter than the equivalent Highline 7.

The body, guts, and actuator carry over from their proven posts.

Apart from the Ti hardware and the carbon fiber shaft, the Highline 11 dropper post shares the Wintek cartridge guts, body, and actuator of their excellent Highline 7 dropper post which I've tested previously. This Highline 11 is in the same 170mm, 31.6, format. I've had great results, and widely recommend, the Highline series. The higher-end Highline dropper posts, the 7 & 11, are covered by a four-year warranty.

As with the original Highline and the Highline 7, the Wintek cartridge Crankbrothers uses has a lower charge than many other Wintek-equipped posts I've tested. The return action is not fast, but it's fast enough for most riders. This was a deliberate choice by Crankbrothers after testing revealed the lower charge allows cartriduges to last considerably longer, which allows for the four-year warranty coverage.

Other than the weight-saving carbon slider the rest of the post from the keyways to the cartridge is the same.

Titanium hardware, carbon head, bonded to carbon shaft. Two piece posts were a concern a hundred years ago but the bike industry is impressively good at gluing things together now.

It's getting hard to keep track of what post stretches to where. 170mm is currently the longest version of the Highline 11.

Wintek cartridge inside. Crankbrothers runs a bit lower charge which results in a bit slower post and significantly enhanced cartridge longevity. The Highline 11 has a 4-year warranty.

All you need to take the Highline posts apart is a 2.5mm hex key and an adjustable wrench. Okay, occasionally you need a strap wrench too but you should really own one of those for every day life anyways?

The 2.5mm hex key goes here. This little bolt just holds the cartridge inline and keeps everything quiet.

Can you even wrench at home and not own a pair of Knipex parallel pliers? In this case you can, any adjustable wrench will do.

This new Highline goes up and down exactly like a Highline 7, which is great. So far I'm only using it on my trainer, but I'll be back mountain biking this summer and will report back with a proper review after exposing it to fall and winter North Shore riding conditions. Then, because it's a carbon shaft, I'm going to report back down the road as well. What does the shaft look like after a year or two of year round use? I know that running a carbon dropper post on a hardtail looks a bit silly so I may ask one of my friends to run it on their carbon-loaded sag-wagon just so it spends some hours in the intended ecosystem.

Are carbon fiber sliding surfaces in the future of mountain biking? I can easily imagine one-piece carbon crown steerer units (CSUs) and not just on the lightest XC forks. There are interesting possibilities for rear shock architecture too - inside and out. I cringe when thinking about the levels of suspension-frame integration made possible through in-moulding. Imagine the level of integration possible on a bike like the Trek Supercaliber that's already one of the cleanest looking full suspension bikes on the market. Sure, it's straight out of my nightmares, but it's clearly someone's dream.

I understand that folks don't like a mess but titanium bolts with lithium grease on them sends the wrong message. Copper anti-seize is the way to go here. You can run Loctite on your Ti rotor bolt/aluminum hub interface if you like.

Ignore the Ti hardware for a moment. The smaller half-barrel washers is something I asked for umpteen times on thefirst Highline, where I modified it with a metal file. This is nice.

Crankbrothers is all about the details. I know, I know, insert jokes about how for years their packaging was nicer than their products.

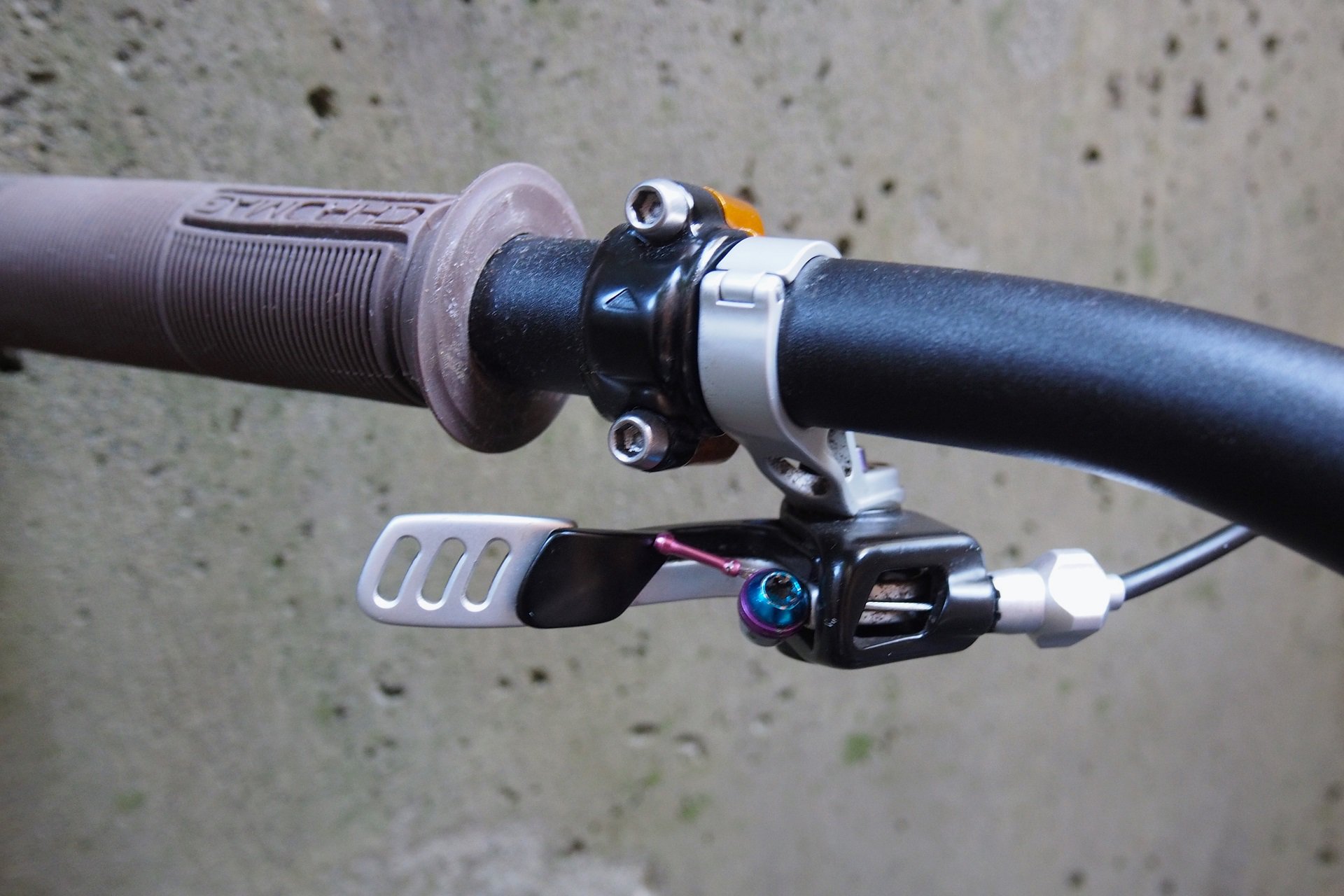

Like most brands, Crankbrothers ships their droppers sans remotes these days. Lately. I've been all about the original Fox DOSS remote so that's what I'm using. It's not a dig on Crankbrothers' remote. Which, I mean, it could have a longer lever.

The BikeYoke Sagma saddle sort of pisses me off. I had to Loctite the bolts that kept coming loose. Then it started creaking. But at the end of the day it's just so f***ing awesome I can live with all the faffing. It's really that great. Best small saddle on the market?

So the post is on my Walt V2 because that's the only mountain bike living at my house right now. Clearly a Highline 11 belongs on a super-bike carbon sag wagon with full AXS and some We Are One hoops.

Being first to the market with something doesn't always mean winning. But, given my excellent past experiences with Highline products I'm inclined to give Crankbrothers the benefit of the doubt here. It's not that I think, other than weight or maybe stiffness-per-weight, that there's any potential advantage to a carbon fiber dropper post shaft, but maybe it's safe to assume there's no real disadvantage, other than cost, as well. Time will tell either way and I'm really excited to know. Your next bike might not have one-piece carbon fiber stanchions, but what about the one after that?

The Highline 11 is available in 30.9 and 31.6 diameters and in 60mm, 100mm, 125mm, 150mm, and 170mm travel configurations. It sells for 400 USD, and includes their 4-year warranty. For more information hit Crankbrothers.

Comments

Perry Schebel

2 years ago

hmmm. only 20-ish grams lighter than an equivalent one-up? the benefit / trade-off, i question it.

Reply

Andrew Major

2 years ago

OneUp wins every time for drop v. length. Get min an extra 1cm. Now for max-length options too.

If clearance isn’t an issue, and 170mm is enough drop, there are a few reasons to get a Wintek equipped post. You won’t have a longer term, lower faff experience (on average) from any other system in my experiences.

———

EDIT: General comment about Wintek v. OneUp. I’m not stressed about a few grams, but Highline 7 v. OneUp, OneUp is lighter (alu v alu) if that matters.

Reply

Timer

2 years ago

Bikeyoke is probably still the king of long-term, no faff reliability. Although at a premium.

The Vecnum Nivo post is lighter than the carbon highline for each given length. Full metal construction. Its supposed to be reliable, but no first or even second hand experience on my side.

Reply

Andrew Major

2 years ago

I'm a big fan of BikeYoke-Sacki's turn-the-box-inside-out-thinking but the real secret-sauce, especially when BikeYoke upscaled production for OE, is not whether your sh*t fails or not it's how you manage issues that matters.

The Revive and Devine are both polished-looking products and they're oh-so-smooth. I certainly wouldn't give them the reliability crown though. Especially not for units sold. I've worked on brand new posts that wouldn't hold position, I've had two friends have chassis failures (that I've never seen with another dropper post at any price point), but it doesn't seem to matter - they'd spend the extra to get a BikeYoke dropper again. Which I think says a lot about BY's customer service.

Long-term, true non-faff reliability, I don't think you're going to beat a Wintek-equipped post with a good chassis (like the Highline series). If a Wintek post is too slowwwww (which it is for some folks), or you want more drop, or space is a concern, or you want that same-day-shipping level of local support then OneUp can't be beaten in the Shore-To-Sky corridor. Anyways, it's cool to support Sacki and his products are generally awesome as is his CS, I'd just push back against the narrative that they're faultless or even lower-fault compared to other products.

Reply

Chad K

2 years ago

How long ago were the chasis issues? I know the first gen had the two part tube/head which had some failures.

I've had an og bikeyoke that's probably 4+years old now and still has plenty of life left in it. And just bought a newer, larger drop revive. Clearly I'm also one of those people who support the brand. I've also used their yoke for an older specialized camber. Any time I've had questions, I've had such great assistance from Sacki.

Reply

Andrew Major

2 years ago

I don't know the generations of the posts, they could have been from the same production run and just failed at very different points. The OE posts I've dealt with have been in the last year. Again, not that sh*t doesn't happen or that BikeYoke doesn't make a great product, I just have been finding lately that a lot of products that are being put on pedestals as comparably faultless aren't as stainless with a more thorough examination.

"I've had such great assistance from Sacki"

Exactly. Again, not that BikeYoke posts aren't good, but I think the true value in all their products is the level of customer support. Sacki is awesome.

Jerry Willows

2 years ago

and how much more $ ? OneUp is local as well.

Reply

Andrew Major

2 years ago

When people ask I’d be comparing Highline 7 against OneUp so similar price. OneUp makes significantly longer posts but I’m happy with a 170mm.

For the record, my daily driver has been a OneUp for ages and that’s what Claire’s running now too. They make a great product but that doesn’t mean there aren’t other differently good products/values on the market.

Reply

fartymarty

2 years ago

And you will need to run a rear Mud Hugger fender to keep the crap off nit in winter... there goes the 20ush gram saving.

Reply

Andrew Major

2 years ago

Hahahaha, I store my bike inside with a heavy lock. I don’t think the extra anti-theft protection of a Muddhugger rear fender* is warranted.

Plus, I mean, I want to test the post properly with a healthy dose of granular Shore muck.

*I want to note that I love my Muddhugger front fender

Reply

Mammal

2 years ago

Definitely solving problems that don't exist (with super expensive solutions).

Reply

Andrew Major

2 years ago

I'm going to copy/paste my response to T0m as I think it sums up my thoughts:

I haven't had any issues with aluminum shaft dropper posts that I would attribute to the chassis being aluminum, including the excellent Highline 7. I'm keeping an open mind in case there is some surprising benefit I haven't considered but for me, the absolute draw of the post is the potential that it's a harbinger not a novelty.

I do admit that in my gut I feel the same way you do. It seems to me that the 'why?' for a lot of bike components using carbon fiber is 'because carbon!' But I think this is an excellent opportunity to have an experience with carbon sliding surfaces if that's the future.

Crankbrothers could have just as easily had my number with a Highline 7 with gold Ti hardware added on. Now that my first impressions are live I've reached out for more information about the choice to go carbon.

Reply

Mammal

2 years ago

I'm not overly impressed by Ti, so not influenced by that at all. And I know you've had very good experiences with the Highline. All that said though, this thing has a comparable weight to the OneUp, and CF generally has horrible abrasion characteristics compared to hard ano, so I just don't see how it can possibly win anyone over, unless they're hell-bent on MOAR Carbon/Ti.

Reply

Andrew Major

2 years ago

Agreed, I'd make the same argument as you for a carbon fiber stanchion or shock body. My motivation in looking at this product is to see what happens. I agree that on the surface the only reason of than weight savings (compared to another Wintek post) is "MOAR CARBON."

Wintek would have to make aluminum cartridges for the system to ditch more weight. The actuator, body, shaft, and head are all very light.

Reply

Jerry Willows

2 years ago

doesn't Wintek make all the OEM shitty posts?

Reply

Andrew Major

2 years ago

No. There are some very different systems used on more budget focussed posts. I think using a Wintek cartridge is the best option because the cartridge can be replaced v. the whole post being replaced. What Wintek post have you had a bad experience with? I’ve ridden and worked on a lot of different ones.

silverbansheebike

2 years ago

Just like my Auntie seize and Uncle loctite always said, whatever you prefer, never go in dry.

I really like the use of carbon here, actually. So many carbon applications in my opinion, don't use the material very optimally (handlebars, automotive body panels, to name a couple), since it is strongest and stiffest parallel to the fiber direction. I could imagine much of the force here being mostly parallel to the fiber direction, with a bit of bending or side loading. If you need a dropper and weight savings is your thing, I think this is a great place for it.

Reply

Andrew Major

2 years ago

I'm not at all worried about it structurally, I'm sure strength/weight it's a win. You addressed it in your other posting, but my concern is about the sliding surface - especially v. the elements through the winter (you did address this in your other post). I mean, I'm not dismissing it outright - I signed up to test the post specifically because I'm very curious.

Reply

silverbansheebike

2 years ago

Oh definitely. I'm interested to see how these play out given more time. Carbon slidey bits is a pretty disruptive idea, I hope it works. Hopefully you do a follow up in the future!

Reply

Andrew Major

2 years ago

Follow up is what I do - for better or worse. I’ll have a review by next spring and then follow up if there’s any change from there (assuming it’s still going)

Reply

Michael

2 years ago

Fancy. The real question is how many Lemoncellos will it take to service it?

Reply

Andrew Major

2 years ago

That's actually a gin-fizz pictured. The longest part of servicing a Crankbrothers dropper (full teardown) is removing it from my frame. That's generally true of most Wintek-equipped droppers. I normally wouldn't even fix a drink to teardown/clean/grease/reassemble one of their posts but my lovely wife made this one for me.

Reply

Michael

2 years ago

Looking up “gin-fizz” sounds promising.

Reply

Andrew Major

2 years ago

It's not something I fix for myself, but I never say no when my wife makes me one.

Reply

Cooper Quinn

2 years ago

What other industries or applications or... who out there is using carbon sliding surfaces in a context at all similar to this?

I'm assuming someone is, or they wouldn't be trying this.... right?

Reply

Andrew Major

2 years ago

I could come up with a comparable. Even a clean comparable (sans granular muck).

Maybe carbon ski/hike poles that telescope? Just came to mind, but seems like a huge stretch.

Reply

Cooper Quinn

2 years ago

Huge stretch; something that isn't really loadbearing, and gets extended/compressed once or twice a day.

There's gotta be some like.... aerospace application or something? Racecars? Maybe? Or maybe Crankbrothers is out to lunch here.

Reply

Andrew Major

2 years ago

Yeah same story with motion systems for cameras. There’s a carbon sliding surface but it’s a huge stretch to compare forces/conditions.

Reply

earle.b

2 years ago

Igus has some info on carbon shaft they offer for linear slid systems.

https://www.igus.com/info/linear-guides-drylin-r-carbon-fiber-shaft-com

Were the regular post upper shafts hard anodized? Or just a standard anodized?

Reply

Andrew Major

2 years ago

Thanks, very interesting.

I believe dropper shafts are always hard anodized? Hard to imagine a cosmetic finish lasting as long as they do. Same as fork stanchions and air shock bodies.

Igus provides a bunch of components for Crankbrothers products. Could be the shaft as well - I’ve asked for more info.

Reply

kcy4130

2 years ago

I wonder if they use some sort of abrasion resistant coating or surface treatment on the carbon?

Reply

Andrew Major

2 years ago

There’s certainly no material hard-coat and I doubt any clear would last better than the material underneath. It didn’t matter to me until now (I mean, it either survives fall-winter or it doesn’t) but I’ll ask.

Reply

Merwinn

2 years ago

Put a full (tube, tools, etc.) Topeak saddle bag on the carbon post of my gravel bike. It promptly wore off about 1 mm off at one location on my carbon post as it repeatedly bounced around on a 2hr gravel ride. While this isn't a dropper, I can attest that repeated friction and carbon fibre are not friends.

Anyone want a $50 Topeak saddle bag? Used only once and now collecting dust.

Reply

silverbansheebike

2 years ago

I know that CFRP resins exist that have hardening particles in them too, these could be used for abrasion resistance... I wonder if something like that was used. Or if it is possible to clad the surface with a nickel plating...

Reply

Andrew Major

2 years ago

Interesting. Thanks!

Reply

T0m

2 years ago

Saves 84g with otherwise little apparent benefit, and an eye-watering price. Maybe it’s stiff AF and flex is the real killer of dropper bushings. I mean it’s possible, but I’m skeptical. I definitely have put rock strike dings in dropper shafts before, and the grinding paste that inevitably develops under the external seal has to be bad for the carbon surface.

Reply

Andrew Major

2 years ago

I haven't had any issues with aluminum shaft dropper posts that I would attribute to the chassis being aluminum, including the excellent Highline 7. I'm keeping an open mind in case there is some surprising benefit I haven't considered but for me, the absolute draw of the post is the potential that it's a harbinger not a novelty.

Reply

AndrewR

2 years ago

Lateral force from the butt sat on the saddle through the dropper shaft is the killer of dropper bushings, not so much the flex in the dropper shaft.

30.9 mm has serious physics based challenges for anything but the shortest posts and the lightest riders. 31.6 mm is just a 30.9 mm with a beefed up side wall so the seat clamp force problem associated with 30.9 mm is less of an issue (use a torque wrench and it is less of an issue anyway).

31.6 mm does a decent enough job on posts up to 210 mm.

Other than BikeYoke using 34.9 mm to give room for bigger bushings and better seals, every other brands' 34.9 mm is just a 30.9 mm with even more weight but no engineering advantages (for the post - the bigger seat tube can give shock mounting advantages) that the 31.6 mm format doesn't already provide.

With carbon frames (and most aluminium frames) the strength of the seat post doesn't add any value to the frame strength, the frame/ seat post already has to be strong enough to cope with the lever effect of the planned length of seat post and the probable weight of the rider that needs a frame of that size.

The technology has existed for a long time to make strong, light 35 mm aluminium tubes (with coatings if the expense justifies the reward). The ability to make a really good 35 mm tube in large quantities with high levels of quality control is well established.

The move to metric shocks was mainly to allow longer bushing and seal overlap for shocks.

Why doesn't the industry just combine the two advances (and they are engineering based advances as opposed to marketing department 'advances') and develop a light weight 35 mm dropper (with the appropriate seat tube and seat post clamp size) and get one with strong, light, easily serviceable and long lasting.

Provide support for legacy post sizes for 10-15 years (about how long the longest lasting version will probably last) but move forward with a format that supports; the lengths we expect on a modern bike (150 - 240; short-ies through to tall-ies), the ease and longevity of use between services and a high value for money ratio.

Also why buy a non serviceable cartridge based post when there are equally good fully serviceable (at home - not "send it back to the factory" posts available?

Reply

Andrew Major

2 years ago

I think the reason 35mm never caught on is two-fold. First, it never should have been called 34.9. It just sounds like another legacy standard (which it is) where 35mm sounds new and streamlined v. 30.9 and 31.6. Second, companies - specifically RockShox - started making longer posts in 30.9 and 31.6.

X-Fusion tried the tact of only offering their longer posts in 35mm (and calling it 35mm) and I know of at least two companies that were planning to make the switch from their legacy sizing when 35mm posts first showed up. But when your frames have used a certain post size for as long as anyone can remember and it's support for as long a dropper as you'd want, why switch?

------

"Also why buy a non serviceable cartridge based post when there are equally good fully serviceable (at home - not "send it back to the factory" posts available?"

I'm working on a piece right now about serviceability v. replacing parts and I've been thinking a lot about dropper posts as part of that. There's a lot to like about Wintek equipped dropper posts. In my experience, this cartridge will easily last four years and taking the post apart to clean and lube it is child's play. At the same time they seem to hold up really well even for riders that never service them and they don't have the cold-weather performance issues of some other systems to boot.

There are some posts where the internals / service are so expensive that riders legitimately question why they wouldn't just buy a new one (especially when there are a running changes to internals).

With these posts, the replacement cartridges are not expensive and the longest part of installing one is to remove the post from a bike. Anyone who can change a stem can install a new one.

Anyway, I've been playing it back and forth a lot and I guess the question I'd ask, if you don't mind, is what home-serviceable-cartridge post would you put up against a (any) Wintek system? I've worked on a lot of dropper posts (including quite a few that aren't supposed to be serviceable) and for how long these last and how easy it is to swap a cartridge I usually end up recommending Wintek anytime I'm asked*. That would generally be a Highine or a PNW but it's pretty hard to screw-up making a Wintek-equipped post.

*Unless if there are space restrictions (max travel / length) - which there often are - or someone wants more than 170mm drop in which case I like the OneUp posts. They're also a swappable cartridge but require a bit more faff with air pressure.

Reply

Perry Schebel

2 years ago

"every other brands' 34.9 mm is just a 30.9 mm with even more weight but no engineering advantages" - this is my gripe w/ the 34.9 one-up - they just add metal to make up the diameter difference (a hefty 140g more, to be precise). has me *almost* wanting to swap to a skinny post + shim.

Reply

Jerry Willows

2 years ago

I have a 30.9 with a shim for my 34.9 and saved close to a 100g....

Reply

Andrew Major

2 years ago

But, you have to use a shim. I don't know that that is worth 100 grams?!

On the one hand, there's the mechanical aspect of adding an unnecessary shim.

On the other hand, you're that guy who shimmed their post to shave 100 whole grams.

Reply

Velocipedestrian

2 years ago

Maximum lego. The 30.9 shifts to another frame easily.

Perry Schebel

2 years ago

i've been known to swiss cheese seatpost shims...

Jerry Willows

2 years ago

nothing wrong with a shim imo... just a piece of plastic. 1/4lb savings for nothing. I would like to see a 200mm wireless dropper that's under $500.

Lynx .

2 years ago

@ Jerry Willows. PB just reported from Sea Otter that X-Fusion have a 170mm wireless post in the works, had a sample there, expected to be finalized and out end of yearish, $400 US. Big bonus over the SRAM version, it seems to carry a replaceable, rechargeable battery like you can buy at any electronic store, which should be much cheaper to have multiple spares so you can carry an extra easily on rides so you don't get stuck out when the battery inevitably dies on trail.

Andrew Major

2 years ago

I didn’t get the appeal of the wireless dropper - not a fan of more batteries in my life - but after using the Reverb AXS I do have to say I love being able to easily remove the post after a wet ride.

On the other hand I’ve walked by two unattended bikes this week (one locked) with AXS Reverbs that could have been mine in 3-seconds using tools I EDC… so… there’s that too.

Jerry Willows

2 years ago

still need a 200mm dropper. 170mm doesn't cut it for me as I like having the seat out of the way on the dh.

Andrew Major

2 years ago

200mm+ dropper, especially living in the Shore-to-Sky but in general as well, I don't think you can beat OneUp for price, quality, customer service.

Lynx .

2 years ago

Jerry, so when you get all this 200mm of drop and drop your saddle, are you going to be like Ibis's migit designer with the huge Napoleon complex and have the tyre slamming into the saddle at full compresion?

Andy Eunson

2 years ago

I’ve had aluminum posts get wear marks under the seal. Perhaps they use a ceramic type carbon material like that used on those carbon brake rotors. They wear well I think and they certainly don’t grip any brake pads I tried on them so that material would be low friction.

Reply

Andrew Major

2 years ago

I've seen plenty of posts worn under the seal. A full teardown again will certainly be part of my long-term review. It slides smoothly but I don't think it's any more of less so compared to the aluminum post. Maybe in the cold it works better? Something I'll think about.

Reply

Lynx .

2 years ago

Hum, hum, this is definitely one to keep an eye on, definitely interested to see/read what the longer terms brings, 6, 12, 24 months down the road.

My only complaint about this article Andrew is this comment, could not quite wrap my head around it/figure it out, makes absolutely ZERO sense to me. Best "upgrade" I ever did was putting a dropper on my Unit, absolutely takes the level of terrain you can ride/tackle up so many levels and makes absolute sense, droppers are definitely the biggest game changer to MTB in the last 15 years.

[Quote=Andrew Major] "I know that running a carbon dropper post on a hardtail looks a bit silly so I may ask one of my friends to run it on their carbon-loaded sag-wagon just so it spends some hours in the intended ecosystem."[/Quote]

Reply

Andrew Major

2 years ago

Oh yeah, I’ve been running dropper posts on V1/V2 their whole existences. Highline 7 and OneUp most recently. It’s not a comment about dropper posts in general but carbon-shafted goes-to-11 luxury posts specifically.

Reply

DancingWithMyself

2 years ago

I am deeply skeptical of this post, but the fact you wrote "I'm inclined to give Crankbrothers the benefit of the doubt" shows just how far the company has come from the early days. Definitely a phrase I never thought I'd see written by a reviewer I respect!

Reply

Andrew Major

2 years ago

When the first Highline was released in 2016 I was beyond skeptical. New owners, new design team, new customer service, whatever. From Joplin, to Eggbeaters, to wheels, I had plenty of beef with the brand. And I started my review process by laying that out. I even called the process 'Postricide' and put together a three-part review process:

Part-1

Part-2

Part-3

It's 2022 and this post is still in play. I road it for ages including on my Walt V1, then loaned it out for a while to a buddy whose post died, and now that I'm converting my V1 from an MTB to an ATB it's ready to ride again for gravel/light-trail/commuter duty.

It's gotten a bit slower, there's a bit of slop in the shaft now (still better than some new posts I've tried), but c'mon!

In the words of Coyote Shivers: "Sometimes reputations / Outlive their applications"

Reply

UFO

2 years ago

I think this just goes to show the amount of damage a marketing company trying to sell mountain bike parts can do, Crank Brothers are probably nearing a decade from their rock bottom.

Yet having said that you also have to give them credit for pushing boundaries. Who was making a good reliable dropper post back in the Joplin days? Despite the propriety and price of the Iodine wheels, they seemed to offer some performance advantages to be able to justify their price tag as well. And best packaging in the industry for the time as well.

Reply

Andrew Major

2 years ago

By the time the Joplin 4 was out there were much better options. I think it was more of a case that where brands like RockShox worked to actually fix products that were far from perfect (Reverb), the OG CB crew did not. The bitd wheel program was awful too and even more than that the customer service was brutal (and so was turnover at the company).

That all changed years ago and both the product and support are excellent but of course it takes time (a long time) to shed past reputations. But yeah, the current dropper posts are excellent, the wheel program is awesome, the pedals are good (obviously both clip-in and flat there's a lot of personal preference in choosing pedals) and very easy to service, and the tools are well-loved. The shoes are fantastic if your grip preference is similar to mine.

Anyway, it's not to say they couldn't improve some features or that they never release a dud product, just that I think the nice packaging, general aesthetic, and name are about all the carries over from the bad old days.

Reply

Andrew Major

2 years ago

This comment has been removed.

Konrad

2 years ago

This comment has been removed.

Alex D

2 years ago

Carbon is not a low-friction material, nor particularly resilient to grit. I'm not aware of any coating that addresses this. Anodized aluminum wins on both counts.

Here's Pinkbike:

> When the lever is pressed the seat lowers out of the way like it should, but it's not as silky smooth as I'd like - there's a noticeable amount of friction as the carbon stanchion slides into the fixed tube.

If they did something with roller bearings like Cannondale's Lefty, it might be interesting, but at the cost of most of the weight advantage.

Reply

Andrew Major

2 years ago

As with many things - forks being my main example - there are production variations to be taken into account, but with dropper posts, I've talked to a couple of brands who've explained that they intentionally limit the amount of lubrication on the seal head initially because of the optics of a "leaking" post if there's an excess that purges.

There are a number of posts I've seen working in a shop that were much less smooth than this Highline 11 initially that were significantly improved with a bit of Slickoleum under the seal. Certainly, as with other dropper posts, this Highline 11 was also improved by adding a bit more lubricant.

Anyway, I'm waiting to hear back from Crankbrothers with more information about their use of carbon for this application but my own experience does make me raise an eyebrow at the quote you've shared. Not saying they aren't experiencing what they're experiencing, but what steps did they take to say whether the issue is assembly v. the carbon shaft?

Reply

Please log in to leave a comment.