TEARDOWN | EDITORIAL

A Chris King RingDrive Hub Experience, Part 1

Chris King Experience

Toyota claims that 85% of the vehicles they have sold in Canada in the last 20 years are still on the road. It's an impressive boast amongst car manufacturers, or pretty much any consumer product, besides craft-made furniture and maybe pianos. When it comes to mountain bikes there are two products that I think could potentially boast bigger percentages: Chris King hubs and Chris King headsets.

I know dozens of riders like myself who purchased a King headset in the 90s and still have it kicking around in their commuter, that classic steel Dekerf which is basically a modern gravel grinder or, thanks to changes in headset standards, plunked into their kid's runbike. Those house-made surgical stainless bearings just keep rolling. It's a great idea to pop out the snap-rings and clean under the seals every once in a while, but how many folks actually do it?

The same is true of the hubs. I'm fairly committed to servicing the ones in my house every year and in decades I've replaced a couple of hubshell bearings* but I know folks who haven't touched their hubs in years aside from the odd touch up of the RingDrive lube. In my experience working in a shop, when they finally come around to having those rebuilt the odds are that there won't be a single component - bearings, drive rings, axles, etc - required.

*single speeding ruins everything

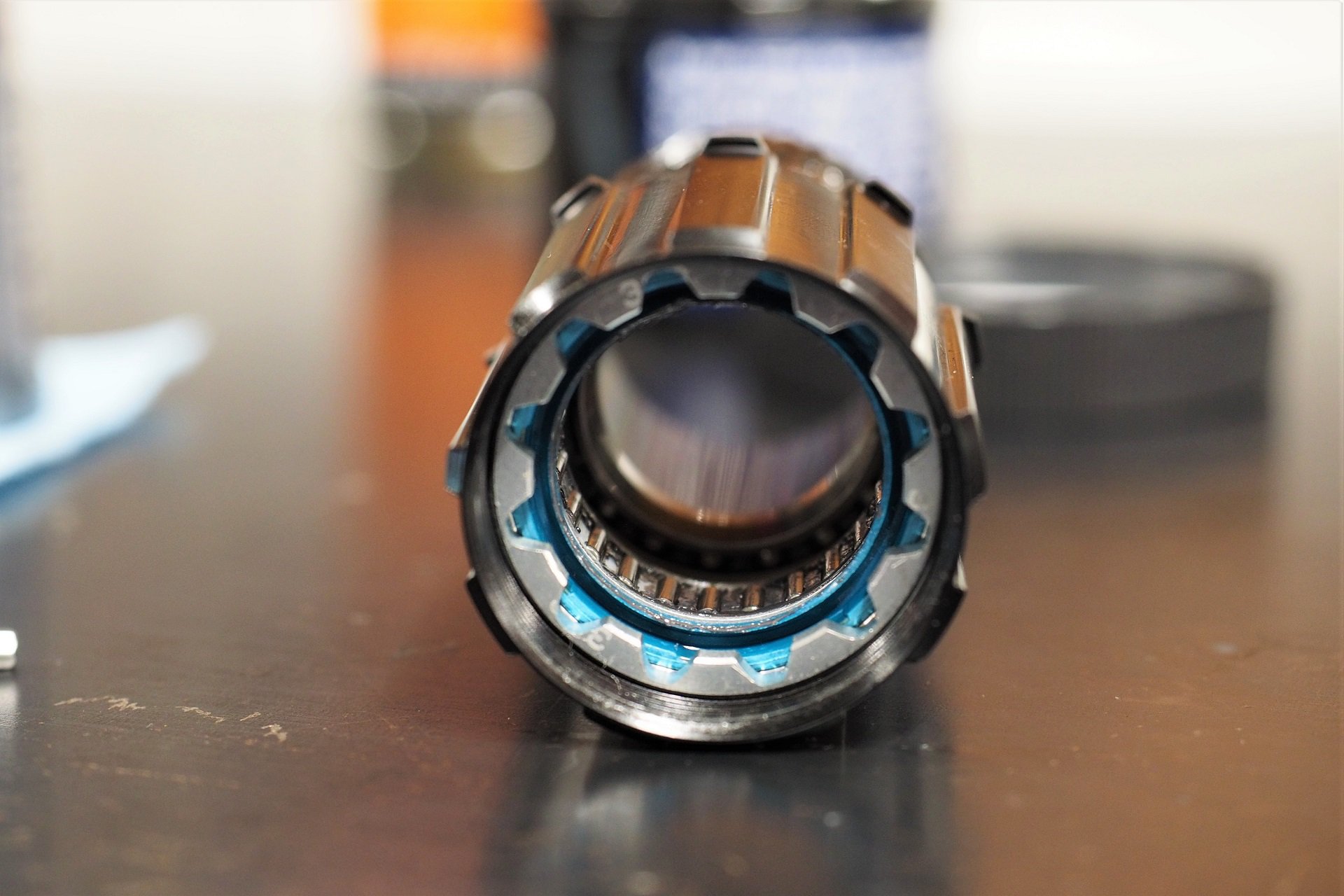

Where the Angry Bees live. Under pedaling loads, the drive shell (freehub) teeth pull the floating, spring-backed, drive ring into the driven ring for 5° of simultaneous 72-tooth engagement. Buzzzzz.

So why are we here? Pete actually planted the seed talking about products that are "worth every penny." I started thinking about the most expensive bike part on the market that I could also claim to be a fantastic value and the Chris King rear hub came out on the top of my list. I think this is one of the best investments in a single piece of mountain bike kit that riders can make. Starting with this introduction and a teardown with Jeff at Bikeroom, I'll follow up with the on-trail experience and some advice on ownership.

Talking purely performance and reliability, even for a rider who doesn't value King's made-in-house, made-in-America, environmentally responsible, employee-centric company culture, the hubs will quite frankly outlast anything else on the market while delivering a once amazing, and still quick, 5° of engagement. That's out of a drive system that has not changed since the advent of the 6-bolt hub standard for disc brake rotor mounting.

One of the big jokes in the bike industry is ye olde 'lifetime warranty' which is of course, for the life of the product - which can be the standard 'thirty feet or thirty seconds' under actual use. In the case of a Chris King RingDrive hub, there is no reason to think that it won't be passed down when I pass on.

The only real change to Chris King RingDrive hubs in 20+ years? New greases and Drive-lube products I covered previously.

A Colourful History

There is, in our modern world, an issue with peddling an identical product year after year, no matter how good it may be. There are reviews of the new I9 Hydra hub, the new P321 hub, the new Race Face Vault hub, but how much press do you get for just turning out the same great product year after year?

Chris King does the standard marketing stuff, like sponsoring the Santa Cruz Syndicate and other teams and riders and their hubs are well-represented any time small-batch bike builders get together. They dominated the fast-engaging division of the high-end hub scene for a lot of years so product awareness may not be as much a factor as price in their reduced local prevalence.

A plethora of anodized colours, heat-treated stainless steel RingDrive system, and made in Oregon - it must be Chris King. King hubshells are "responsibly lightweight" which is to say they're built to last forever.

One of the marketing strategies Chris King does use is limited edition colours, like the tasty Bourbon Brown, which is currently on its last run according to the King Instagram page. Thee hubs I'm testing are Violet, which was previously a limited edition colour but is possibly here to stay now because it's the best. Well, other than Pink maybe, which is another colour that has currently been curbed and Green, which never goes out of style, but currently has.

You can't please everyone all the time but Chris King offers eight standard colours, plus Bourbon and if none of them is just what you want then hang on to your wallet because they do a few special runs a year.

Bearings

Before thru-axles were common, Chris King's threaded axle hubs, which could also accept thread-in QR adapters, were often seen rolling around with a bolt-on configuration using their custom Funbolts. It's a cheeky name because they were the opposite of fun to manufacture, being stainless steel. In the early days they were produced manually and the job usually fell to the newest machinist on the shop floor. I think as much as any King product, they epitomized two of the tenets of Chris King's manufacturing ethos: 1) make it in-house, and 2) make it exactly to the vision, even if it takes longer and costs more. A pair of off-the-shelf 8mm hex bolts with washers and an axle threaded to receive them would hold my rear wheel on, and wouldn't cost 70 USD for a pair, but a compromise is a compromise.

Another product that aligns with Funbolts is bearings. The stainless steel and ceramic bearings in every Chris King product are house-made and rebuildable and a lot of riders will never replace one as long as they own their hubs. When I hear folks talking about having to buy bearings for their King hubs I'm always suspicious about whether a) they know the bearings are rebuildable, and b) their frame is properly aligned.

It's much easier to remove bearings with the hub laced into a wheel but anything is possible with the right tool.

Bearings get opened, cleaned, and lubed as part of a service. Many riders will never need to replace one as long as they own their hub.

This is a brand new bearing, but it could easily be a decade-old example that Jeff has just cleaned up. The balls and races are heat-treated surgical grade stainless steel.

Installing the new Chris King silver bearing grease. It's meant to spin faster and stay in place longer. I'll cover that when I open up the hub for Part 2.

You can (should?) use gloves for this step but Jeff's mechanics hands are basically made of leather.

Putting everything back together with the hub tool. I'm not a metrics person but I wish I'd kept track of how many times I have used it.

All the bearings are cartridge-style except the needle bearing supporting the axle in the drive shell (freehub). I've seen lots of solutions to hubs eating their drive side hub shell bearings, from oversized cartridge bearings to double-stacked cartridge bearings, to companies just putting their heads in the sand, and this is easily the best way to manage those forces.

Evidence? Well first off, it's impressive how long Chris King bearings last as a unit throughout the hub and also how many high-end street & park BMX hubs use a similar layout. If it's good enough for folks sideloading the hell out of 20" wheeled bikes with as much air in the tires as I run in my fork, then it's good enough for me.

The needle bearing assembly in the drive shell (freehub) supports the axle from heavy pedaling loads that eat the drive side hub shell bearings on many hubs.

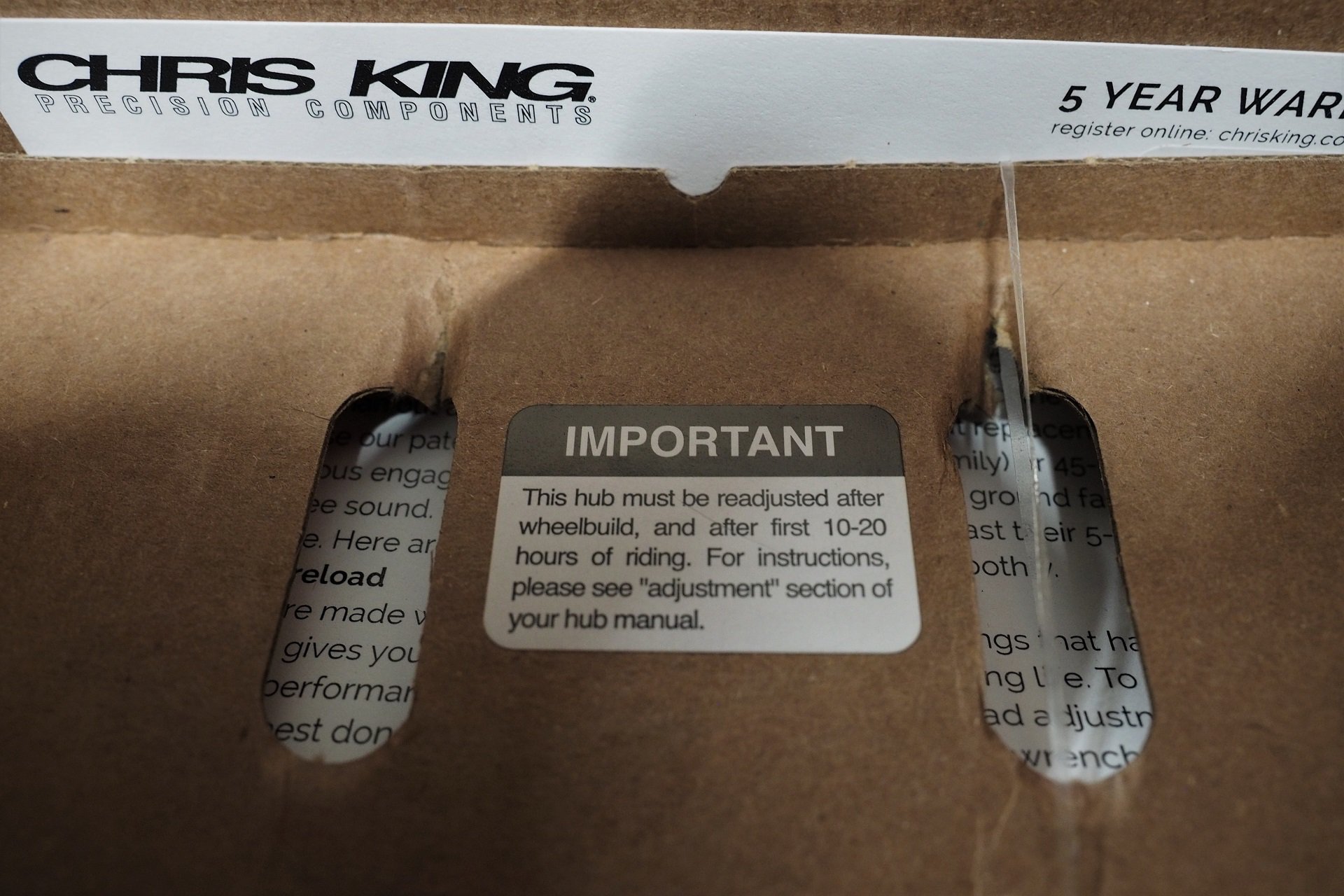

Each rear hub has four bearings. In the drive shell, there is an unsealed cartridge bearing and the needle bearing. In the hub shell there is one on each side: a small hub shell bearing on the disc side and a large one on the drive side. Both the balls and races are made of heat-treated stainless steel, unless of course, you pay for a ceramic upgrade. If you do, there is an extended break-in period as the balls burnish the races, which is one of the reasons that King hubs need to have their tension adjusted from time to time.

Bearings also have more drag on an unbuilt hub then they do once laced into a wheel. This is because Chris King takes into account the effect of spoke tension on the shell. If you ever have the opportunity to handle a King hub, front or rear, right before and after lacing a wheel it's an interesting real-world test that sounds a bit like bullsh*t until you experience it yourself.

Bearings are also one of the key places Chris King delivers value over competing high-end hubs. A Boost King rear hub is 20-25 USD more expensive than a DT Swiss 240 or Industry Nine Hydra but the bearings make them a strong value argument in a lifetime cost comparison.

Angry Bees

My wife, Nina, had never ridden a high-end hub when she had her first Chris King experience and it was a remarkable case of love at first ride. Of course, she noticed the distinctive Angry Bees sound. It's not as loud as many hubs on the market today but at the time it was towards the bolder end of the scale. RingDrive still has a unique hum that only the Industry Nine Hydra comes close to replicating. Then, she noticed the quick engagement.

I know a lot of experienced riders who couldn't give two shakes about how quickly their hubs engage. Personally, faster is better and I'm a better rider in technical terrain with a quick-engaging hub. I'll take a maximum of 10° and I'd prefer fewer. I actually think it makes a bigger difference for less experienced riders as the timing of power strokes and ratcheting is much easier to sort out.

At some point - whether it's 7, 3, or 0.52 degrees - I'll accept that it becomes a bit gratuitous but it's very cool the first time someone gets on a high-end fast-engaging hub and notices a difference in their riding. In Nina's case, the hub in question now laced into its third wheel, has never needed a part replaced, and I suspect with basic routine service it will serve her forever without ever skipping a beat.

The drive shell, axle, and bearing adjuster are all anodized black these days instead of silver. There are HG, XD, and Microspline options.

The heat-treated stainless steel drive & driven ring assembly interface with the drive shell to deliver 72-points (5°) of simultaneous engagement.

That Angry Bee sound and quick hub engagement are delivered by the simultaneous meshing of the 72-tooth Ringdrive system. The buzzing heard while coasting is the teeth of the drive & driven ring hovering next to each other. Hammer on the pedals and the teeth on the drive shell pull the floating drive ring into the driven ring, assisted by the drive spring and locking everything together.

The drive shell is aluminum and I have replaced one before because the teeth were no longer meshing nicely with the stainless steel drive ring. For single speeding, I use wide-body aluminum or steel cogs that aren't too mean to the aluminum drive shell but I sometimes wish, being a non-weight weenie pedaling around 1700 grams of rubber per wheel, that they still offered a stainless steel drive shell for that buy-it-only-once factor.

The drive & driven ring sit a lot deeper in the hub than most drive systems (behind the drive side hub shell bearing).

The drive spring pushes the rings together when I'm pedaling. The harder I pedal the harder the drive shell teeth engage with the ring drive, so these hubs never slip.

I ditched Chris King's white RingDrive lube years ago in favour of some synthetic motor oil, but the new King 2.0 lube seems to have similar resistance and they promise increased wear life as well.

King sells replacements for the stainless drive & driven rings, but the only ones I've seen replaced have been run dry in unserviced hubs for years. The way that the RingDrive system works, the more force that's put into the system the harder the drive shell and drive rings lock together. The system is fully supported under pedaling loads such that wear and slippage do not happen.

Chris King claims that it's been tested to 800ft/lbs of torque so I'm certain even the most massively motored mountain moped riders are in the clear here.

North Shore Teardowns

My hub tool goes back 15 years, and with a household of Chris King hubs, I'm positive that it has paid for itself. The tool works just as great as the first time I used it and, knock on wood, while all the individual parts are available, each component is tickety-boo.

My own hub tool goes back at least 15 years and works with any King rear mountain bike hub and I've never replaced a thing on it.

For a number of years my tool sat lonely in a box because Craig Sabourin, one of the best mechanics I know, used to service rear hubs for me when he'd booked in a batch of them. Then he left Vancouver over that whole affordable housing thing and joined the rest of the grey-haired dudes at Kelowna Cycle – a big loss for North Shore riders and a solid gain for anyone pedalling bikes in K-Town.

The front and rear hubs both have bearing preload adjusters that are accessed with a 2.5mm hex key.

Front axles are machined one-piece aluminum assemblies. Chris King has streamlined their mountain bikes hub options to Boost or Super Boost only now.

The rear axle is a fixed assembly designed for maximum rigidity. It's composed or aluminum and stainless steel.

Tighten after wheel build. Tighten after 10-20hrs of riding. Then check the tension once in a while as the bearings wear in.

Build & Ride

I'm increasingly a fan of WTB's KOM rim series. They have the angled hole drilling I came to appreciate with the beautiful Velocity Dually, they're relatively light, options abound with a Light and Tough option (mirroring their tires) and in most sizes, they air up tubeless really nicely, and they're relatively cheap.

I run the Light version in the front, the Tough version in the rear and I have yet to dent one. I run the tough casing Vigilantes in big sizes (2.6 or 2.8) on my full suspension bike, and on my hardtail I've mated them to CushCore inserts. I'm running an i40 front | i35 rear with the Chris King hubs and my friend Dumpster Bear laced them up for me using Sapim spokes and TLC Brass nipples.

My friend Dumpster Bear laced up the Chris King hubs to WTB KOM rims. Light i40 front and Tough i35 rear.

The wheels are being tested on my Waltworks single speed and my Marin Alpine Trail. The HG drive shell is mated to a BOX 11-46t 9-speed cassette & derailleur, and a friction thumb shifter.

WTB Vigilante Tough Casing 29x2.6" rear. On the front wheel I'm running a 29 x 2.8" also with the Tough Casing. No inserts.

The hubs were both tightened after the initial build and I'm now at the point that I've checked preload on each of them and tightened the rear a bit. The initial break-in has happened and they're both spinning notably smoother than out of the box but the rear hub has nothing on a couple of years-old examples Nina and I have in the household. As memory serves they'll be pretty much there after a few months of hard use so I'll plan to craft Part 2 once they hit full spin. It's easy to imagine them being laced into a plethora of rims over my lifetime.

There's no question that Chris King hubs aren't cheap but they're right in line with plenty of high-end options these days in a comparative cost of ownership the King bearings will make up a 20-25 USD difference many times over. In my experience, a rider creates their value via hours, miles, and experiences as the hubs are up for anything.

Chris King ISO Boost rear hubs sell for 460 USD (HG or Microspline | +44 USD for XD) and the fronts for 241 USD and there is a wealth of information at Chris King.

Comments

MJ1

4 years, 1 month ago

Kings are king. This article points out how cost effective they are. I've got quite a few rear King hubs with one rear being over 15 years old and still going strong, and I bought that one used. It is still on my main trail bike. Got the hub tool years ago but its really not needed for yearly/bi-annual maintenance. A 99% clean and lube can be done without the tool in about 20 minutes with hex wrenches, WD-40, Triflow, and lube. When I re-build the wheel once every few years I send the hub back to King for a full rebuild and for any upgrades they typically do and minimal charge. Only problem with King... they no longer make the "Pewter" color hub. That was by far the coolest color.

Reply

Andrew Major

4 years, 1 month ago

The Matte Slate is pretty close to some generations of Pewter but I know what you mean. Somewhere, out there, are a set of those magic slightly purple Pewter King hubs laced into Silver 29" Velocity Blunt rims with a mix of purple and gold spoke nipples and if I ever see them rolling by it's going to take a f***ing army to keep me from reclaiming them. Bike Thieves SUCK.

I was with you until the whole TriFlow thing. Where are you using that? If you haven't, try the new 2.0 Ring Drive lube, I think you'll be really impressed. Anywhere else you're using TriFlow, Dumonde Tech Freehub Oil is an awesome alternative (even in cable housing). I'm officially a TriFlow free household now.

But yes, a quick clean with just popping the driveshell and axle out works great.

Reply

Shoreboy

4 years, 1 month ago

Im still rocking pewter (which have of course turned to that purple/pink color that CK hubs do) on my current ride! 142x12 rear and 15x100 with MRP Boost caps for the front.

Reply

kekoa

4 years, 1 month ago

Need more pics of the King tool. That thing is hawt! I need to get mine and look at it now.

Reply

Andrew Major

4 years, 1 month ago

Good advice! I’ll add some the comments.

Thanks!

Reply

dave_f

4 years, 1 month ago

I picked up a Chris King classic rear hub used (don't know how many miles were on it, but the anodizing was faded on one side) back in 2009 with the stainless freehub. Since then I've put about 40,000 miles on it commuting to work year round. I clean and relube the bearings and spline drive about once a year, and I replaced one of the outboard seals at one point. At this point it looks like it will keep running smoothly till I retire.

I was able to get a good deal on some new CK hubs and parts including the bolt-on axle when the move to boost happened. I went so far as to machine a set of 135x10 dropouts for my Banshee Rune (the newer ones only support 142 or 148x12) so I could keep running the rear hub for bikepark use.

I think for awhile hub shells were available individually. Do you know if they still offer individual hub shells, it would be nice to be able to just swap the internals and axle if necessary at some point?

Reply

Andrew Major

4 years, 1 month ago

That’s an awesome tale about a hub! One of mine was used too - couldn’t say no, customer in the shop “upgrading” to save weight. It’s on a buddies bike now. I’ll admit I scroll the buy&sell once in a while to see who’s selling off their 26”/142 wheels. Boostinator kit, lace in a favourite rim; ride!

I’m sure you can track down a black one at the least. I question why you would because your hub has the kind of story bike parts rarely develop anymore with the patina to go with. I know the King R45 is becoming the de facto 135/142 King option but I’m certain they’ll support their legacy product - it’s King.

Reply

sralph

4 years, 1 month ago

I was able to order a Boost hubshell and boost axle and convert the rest of the internals over when I moved from a 142 frame to a Boost frame. Converted the old hubshell into a penholder for my desk.

I still have my original CK headset, which was purchased as a 1 1/8" threaded headset for my GT Zaskar LE and later converted to threadless with a King conversion kit. It's still going strong on my Surly Big Dummy...almost 30 years old now

Reply

Andrew Major

4 years, 1 month ago

Very cool; I’ll definitely mention that hack in Part 2. That actually explains some of the hub shells I’ve seen for sale.

Did you hang on to the threaded uppers?

Reply

twk

4 years, 1 month ago

Did I just read "friction thumb shifter"?

If I did -- how does such a setup feel on the trails in the modern age? While my min-maxing is certainly a bit more budget-oriented, I hold on to my 10spd saint shifter as that thing just feels nice. But if I break it at some point...

Kudos to you, I always love reading pieces like this!

Reply

Andrew Major

4 years, 1 month ago

10spd Saint shifter, 11spd XT derailleur, 11-46t SunRace cassette = my favourite ‘rapid fire’ drivetrain.

I’ve run a friction thumbie (no indexing) for years on my commuter and on/off on my FS bike. It’s an old Paul Thumbie plate, older DuraAce 9-speed Barcon shifter. Currently powering a Box 9-SPD system but more recently Shimano with an 11spd cassette and before that a 10spd.

Not for everyone, and I don’t race anybody, but I love it. Makes perfect shifts a game and I’m way smarter about my shifting points. It makes me faster/smoother as I focus on momentum instead of shifts. Like a multi-geared single speed?

Anyways it’s struck a bit of a cord on Instagram. Folks tag me in their moderin-bike-with-thumbie setup or message me pics. There’s a surprising (to me) number of folks out there experimenting.

Reply

Rob Gretchen

4 years, 1 month ago

I had a Chris King headset many years ago before they were using a split ring for managing proper preload.... did not have a good experience with that headset. It was rasta, that was the highlight. The newer headsets and hubs look great but the price is exorbitant. And 5 degress of engagement is so 2019.... ;-)

Reply

Andrew Major

4 years, 1 month ago

Yeah, had to stay on top of fresh top-cap assembly o-rings running those on longer travel bikes, especially if steerer tube was under spec for OD, and even then they were more of a road/XC product. Evolved into the new model which is excellent though and you can update older ones... or retire them to a commuter etc.

Not cheap to the yearly bike flipper. In my house, we’ve had most our King stuff so long it’s been forever amortized in our minds. Look at the drive system, look at high end up with a basic pawl layout and I think the price difference is justified even for someone who can’t justify the investment.

Yeah, I know. But I’m jumping back and forth between 5 degrees and ~ instant with the Hydra and 5 is good.

Reply

Rob Gretchen

4 years, 1 month ago

Just razzing you about the 5 degrees... I use Hope's engagement of 8.2 degrees as the minimum for customer recommendations. Although DT Swiss hubs are a bit of an outlier in this regards as they are so darn good.

Reply

Andrew Major

4 years, 1 month ago

DT 350 is such a value, if you don’t care about engagements.

It’s valid point though as King are 5 and I usually am riding <3. It’s pretty cool when you think that the prevalence of quick engaging hubs is fairly recent. My first King hub was mind blowing!

Reply

Andrew Major

4 years, 1 month ago

I actually have to come back re. pricing. Comparing apples:apples for high-end Boost hubs (USA retail pricing) the Chris King hub is $20 more than a DT Swiss 240 and $25 more than an Industry Nine Hydra. I mean, they're all expensive but the King bearings alone will cover that difference multiple times over the life of the hubs.

Reply

Shoreboy

4 years, 1 month ago

You beat me to the punch on this. Pricing is all very similar for the high end hubs, but the longevity of CK hubs makes it a no brainer for me if im getting new ones. Oh...and the angry bees! Cant live without them when Im coasting down the trails.

Reply

Timer

4 years, 1 month ago

I don't think it makes sense to compare CK to dt 240 without considering weight. The main advantage of the 240 over the 350 is lower weight. If that doesn't matter then the 350 is hard to beat on value.

Reply

Shoreboy

4 years, 1 month ago

3 sets of King hubs on current bikes. All sets are at least 10 years old, and I think one set is 15. They have gone from QR to FunBolts to 142 and I have never had to replace a bearing on any of them. Newest build is getting a new set of Boost hubs. Id like to say its because of the spacing (but like you said I could Boostinator them), but it has more to do with the pimp Matte Slate color to match the CK headset and BB. Yes....I am a CK fanboi and have no problem admitting it :)

Reply

Andrew Major

4 years, 1 month ago

Matte Slate is a sweet colour. It's not currently on the list but when my wife saw the 'Apple Green' they had for a while she was definitely considering reasons for a fresh set of hubs. And yeah, most people I know have never had to replace a bearing - just overhaul them Do you do your own rebuilds?

Reply

Shoreboy

4 years, 1 month ago

I definitely do my own rebuilds. I share a CK hub tool with a friend, and I have only had to overhaul them once or twice in their lifetime. It was more of a feeling of I 'should' overhaul them rather than a need. I opened up all the bearings to put some fresh grease in them, and they all look brand new.

Reply

Andrew Major

4 years, 1 month ago

I was thinking about this whole "sharing" thing riding home from work today and I have to ask - whose house does the tool live at?

'cause it's not really, really, yours if you can't pull the tool out and mess around with it anytime you want. Is it one of those Stanley Cup things where it lives at one house and then the other?

It's a funny aside, but the number of hours of my daughter's life that she's happily entertained herself playing with my King hub tool or my Wheels Manufacturing bearing press set almost justifies the cost of either just in being able to get stuff done in the shop.

Reply

Shoreboy

4 years, 1 month ago

It basically resides at whoever's place did their overhaul last. Its not like you ever need an 'emergency' overhaul with CK hubs. It has definitely been used over the past 10 years (maybe 2x for each hubset?), but it certainly isnt a daily use tool :)

Reply

Heinous

4 years, 1 month ago

I’ve sadly found I9 and DT vastly more service intensive, and the only singlespeed hub set up I would date compare is Paul Comp WORD with a White Industries freewheel combo.

I’ve found that set up bullet proof. I’m not sure if it’s the simplicity and quality of manufacture but bearing last forever and are a cinch to replace. The trials freewheel engagement is pretty good too.

I recall joking recently how offended I was to have to replace bottom brackets and headset bearings (FSA and Praxis) after years of running CK where that’s just not a thing.

Reply

dan_l

4 years, 1 month ago

I run CK headsets and BB's. The Headsets are great whereas Cane Creek just rust in weeks and need service monthly.

The CK BB's are also great but don't last forever. This is mostly due to SRAM's crap GXP setup, it wears the non drive side bearing abnormally as it puts 100% of the thrust load from both pedals into this single bearing. CK BB's last 2 years in my application whereas SRAM BB's last 4-6 months.

Reply

Andrew Major

4 years, 1 month ago

This. Hidden deep down behind all the jokes/wrath about the 28.99mm sizing, SRAM DUB is a WAY better system than GXP and also doesn't seem to have all the bearing issues that accompany putting a 30mm spindle into a PF92 pressfit shell. Also, don't love-love their cranks but do love their three-bolt mounting system.

I'm running a RaceFace Aeffect R crank in an old Chris King bottom bracket that I recently reconstituted. It's a fantastic mix of a 24mm spindle and Cinch (which brilliantly uses an existing tool that everyone has waisting away in their tool box).

Anyways, all this reminded me that I have two eaten CK BB's that succumbed to single speeding which I should pay to ship back and have rebuilt. Still plenty of 24mm cranks in my house.

Reply

dan_l

4 years, 1 month ago

SRAM dub is better, I converted my MTB over last year. That does not forgive their sin of engineering GXP though.

In general sram engineering as well as their piss poor manufacturing tolerances drive me crazy.

Reply

Andrew Major

4 years, 1 month ago

Be very, very careful what you say. I cheekily made fun of the appearance of their (excellent performing, but sort of expensive for what they are?) Eagle X-Sync chainrings ONE TIME - I may have compared their appearance to the product of drunken whittling - and did I hear about it... I'm pretty sure SRAM Tchermany has been after me ever since.

Reply

dan_l

4 years, 1 month ago

The GXP is a factual engineering fail. I hope someone sees this and takes it to heart. The non drive side bearing in that application takes more force than the bearing is rated for. It fails quickly due to an engineering mistake.

The tolerance between the crank shaft and bearings is a manufacturing flaw. Water is allowed to weep by and saturate the bearings from the back side. The plastic bushing used on my BSA application is another engineering fail. It must be being used to take up play in the system and or to limit creaking.

Dub uses o rings on the inside of the bearing races. I think this is in an effort to pump out shit tolerances and use a flexible o ring to take up the slack.

The SRAM tolerances are shit, this is fact. $20 blender motor shafts have better quality. If companies like Hope and CK can make hubs that don’t creak and bearings that last 5+ years between service (my experience) then a huge company like SRAM should be able to do the same for a crankset.

Would you like me to share my experience with a Sram rear hub? Or perhaps their derailleur jockey wheel bearings that seize? Or perhaps their shock shaft pivot bearings that seize and needed replacement with a quality bearing that is lasting 4x longer and counting?

Oh yeah, then the seatpost...

Dear SRAM, pm me so I can test out your designs before they go to market.

Heinous

4 years, 1 month ago

LOL. I recall being in the pits wrenching at a CX World Cup one year and innocuously (kinda) asking ‘hey, what’s the deal with all the spindles being 5mm+ too long for the shells? Is it spindle length or a they not bonded deep enough in the arm?’

Head sram tech looks awkward and says ‘I don’t know what you mean?’

Senior sram mechanic starts screaming ‘then why did I rebuild every athlete’s bike with new cranks today?!??!?’

Reply

Andrew Major

4 years, 1 month ago

White Industries Freewheels are awesome! It's too bad they haven't done an ENO hub for a thru-axle setup... is the kind of thing a single-speed evangelist would say... but I am not one... The Trials freewheel is pretty good for engagement at 5°.

Historically, running single speed, the only bearing I EAT on I9 has been the big (single) hub shell bearing behind the freehub. It doesn't seem to matter what quality of bearing I replace it with because it's taking a tonne of load and single speeding ruins everything. That said, the ABEC-5 Enduro bearing in the Hydra hubs I'm testing is so-far-so-good.

The big joke is all the guys running King BBs who re-grease them on the bike and then when it comes time to take them out there's a torch involved! Turns out having your BB in your frame for years on end has some cons too!

Reply

bikesandbarley

4 years, 1 month ago

Pardon me for a bit of a tale but I am a Chris King fanboy for life.

I bought my first King hub in '99 at Mountain and Beach, Classic front. Followed it up with the rear in '99. At the time it was so easy to break down the hub with a couple of 5mm allen keys but I was dumbfounded as to how to service the driveshell bearings so I gave them a call (CK when they were still in Santa Barbara) They asked me first off what serial number I had and informed me that the Ringdrive was aluminum and that they would supply me with an upgraded steel version. They asked me where I lived and at the time they were pretty convinced that no-one in Vancouver had the tool and offered to lend it to me to do the service. When they told me how much it would cost to buy at the time I jumped on it. I still have the original printed service manual they sent with it but I have misplaced that original Ringdrive assembly but I do remember it was red.

When disc brakes came around (2001?) I made another phone call. They were in Redding Cali. at that time. They offered me a good price on Universal Disc Hubshells and disc adaptors. I had the tool so it was a no brainer to convert. After cleaning and boiling the hell out of the original shells I turned them into salt and pepper shakers because they sold the base caps and shaker caps to cover the bearing holes as accessories.

Those original bearings had been in the Disc hubshells until 2014 when the ring drive side no longer needed the tool to extract it and would just fall out of the shell. I had already purchased a 20mm front Disc a few years previous but replaced the "wornout" rear with a new 135mm ISO. That old Unversal Disc Shell is now a chilli shaker because well...

The next year my frame shits the bed and Boost was the only option. King had not yet produced their boost rear. The ISO hub was a bench warmer for over a year until they had developed new shells and axles. The 15yr+ bearings went into the "old" ISO hub and were sold to a very happy new to him owner and I have been running the Boost hub on the "old" ISO bearings for 4 years now.

King makes a ridiculously durable product and they follow that up with amazing product support. I can't see myself running anything but the Angry Bee in my lifetime.

Reply

Andrew Major

4 years, 1 month ago

Thank you. It will be a sad day (for me) when it arrives that I can write about mountain biking in Vancouver and Rod Kirkham's name, shop, and bike brand won't come up. I'm not really nostalgic for a lot of the way shops were back then (I think in many aspects when it comes to the customer experience shops are better now) but there was still something special about Mountain & Beach, Cap's ProWorks, Cove Bikes, and etc. Then there was the sea of orange and green Santa Cruz Hecklers, Bullits, and Chameleon's hanging from the ceiling in Kim Steed's shop, or talking to Dan Sed at OnTop about custom metal over a beer while he laced a wheel or pressed a King headset in.

It's funny, I really hadn't considered swapping shells/axles to move my drive systems over to current frame standards. The right price on a used King hub with good guts, an axle, and a hubshell may be the least expensive way to get into an amazing Boost or Super Boost hub.

Cheers!

Reply

Kyle Doherty

4 years, 1 month ago

I noticed that the mechanic has cut off the rubberized coating on some of the Wera hex keys. Sometimes he leaves a band near the elbow and some times it's near the tip of the long end. Would he mind sharing the reason for this? Is it just to toss them on the magnet more easily?

Reply

Andrew Major

4 years, 1 month ago

They've actually just slid down - they're static position is all at the top. When you use Wera hex keys a lot the sleeves get loose and slip down so you cut them short and push them up so that you can still quickly identify what you need by colour but also get a solid grip on the tool.

Reply

Reuben.Sandwich

4 years, 1 month ago

I had 5 King hubs in my fleet just before selling my old bike a few years back. I borrowed my buddy's king tool and gave them all a birthday. What a waste of time! One set was from 2001 and had seen AM duties mostly one set on my DH bike dates to 2008 and the lonely rear hub was a second hand DH from a young guy on the Australian Junior DH team. It had sure seen some mileage and wasn't as nice inside but boy was it still smooth! I could rebuild hubs all day long with that thing. It's just an absolute pleasure to use!

I'm running Project 321's on my Slayer now (love them!) and occasionally miss the angry bee but i love the almost -silence just as much.

Reply

Peter Leeds

4 years, 1 month ago

I would like to give a prop to Hadley. Not very common nor seen but IMO they put Chris King to shame (no small feat). They are run out of a garage and are definitely small but the product is like a fine Swiss watch. At the time, almost 18 years ago, I had to get a set of hubs for my then new 03 Foes Fly. I just came off Razor Rock Racing hubs, which, if anyone remembers, made one of the few 20mm thru axle hubs for the rear. This was how the Ellsworth Dare was fitted, and the RR hubs were terrible. Improperly sealed, minimal drive side bearing support...you name it. Couldn't get rid of them fast enough. Enter the Hadleys. Freehub is titanium and engagement is by pawls. My original hubs, on the wheels still on my big bike, have never had a service (and the entire life of the bike has been Shore only). I took them apart 5 years ago, I think, just to look and nothing was awry. Bought a free hub rebuild kit just in case, but they keep on going. When I built up my new bike just over a year ago, guess what hubs I got, and I had the choice. I found CK to be expensive, and although they are lighter, perhaps. it is not rotating weight. And to get almost 18 years (and going!) on a set with no need for new seals, bearings or whatever...remarkable. I mechanic my own bike and have the tools...never needed any side load adjustment...nothing. To my knowledge, the best place to get parts is through Balle Racing website.

I cannot say enough about Hadley. The epitome of a small company that stays tight and small but delivers the goods.

Reply

Pnwpedal

4 years, 1 month ago

King bearings are, without a doubt, some of the best bicycle bearings ever made. Chris puts a ton of attention to detail in all parts he makes but the bearings are a step above and beyond - the level of precision and tolerances held are impressive. They also literally get faster as they are used. Many racers run their new King hubs on their practice bikes, and keep the broken-in faster hubs on their race bikes to eke out that extra second. No off-the-shelf cartridge bearing can come close.

(Disclaimer: I once worked at King and will always be fond of the parts.)

Reply

Please log in to leave a comment.