2-MINUTE EXPERT

Bio-lubricants: Fast or Friction?

If you're anything like me, the sound of a dry chain is like glass shards being ground into your ear drums. It's hard to hear someone's drivetrain being powdered, and it's so easy to fix the problem. We all know it's important to keep our chains lubed, but...why? I had a discussion with Isaac and Alex Marangoni, the father and son team behind Whistler Performance Lubricants (WPL) to learn about how lube works, how to choose the right lube for your type of riding, and what they're doing to develop and market bio-friendly lubricants. And despite my best efforts, this article will take closer to five minutes to read than two - but unless you studied chemistry, you'll probably come away with a much better understanding about lube, as I did.

Why Do You Need to Lube Your Chain?

Safe to say that all of you reading this understand that a well-lubed chain is vital to a properly functioning bike. But for the sake of your buddy with a dry chain and selective hearing that you're going to send this article to once you're done reading it, let's recap. There are two very important reasons to keep your chain properly lubricated:

- Efficiency: A well-lubed chain will transmit more power from your legs to your wheels, thanks to a smooth-running drivetrain.

- Durability: Lubrication will prevent premature wear. This becomes even more important when riding in adverse conditions - dust, dirt, sand, and water all want to tear into your drivetrain like a troll in the comments section of an article behind a paywall. And it's doubly important when you consider the cost of a modern high-performance drivetrain.

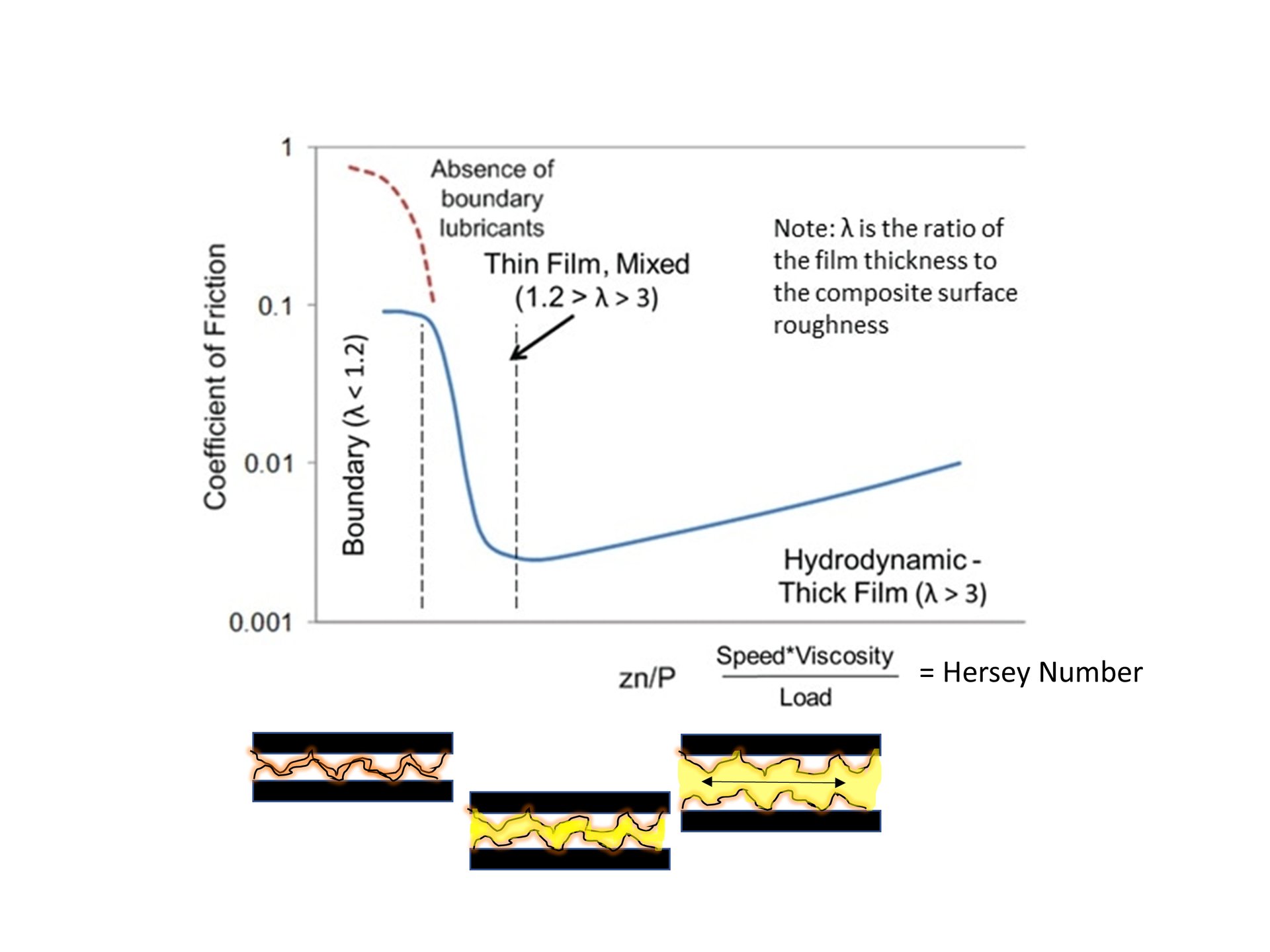

Nothing surprising there. What I find much more interesting is the why. The best way to understand what's going on with lube on your drivetrain is to discuss the Stribeck Curve. Here's where we start to get a bit nerdy.

Any lube is better than nothing, but sometimes a wet or dry conditions specific lube will last longer and work better - or at least require fewer refreshes and less cleaning.

The Stribeck Curve

A lubricant's job is to decrease the coefficient of friction between moving surfaces (what we called efficiency above) and help dissipate heat, and it also needs to stay in place on the metal under high loads, because if it's removed, it obviously can't do its job anymore. Other than the obvious impact on efficiency, lube that goes AWOL will also lead to premature wear. What I didn't know before was that the relationship between lube and the metal it protects changes based on speed, load, and and lube viscosity, which is a function of temperature. This relationship is characterized using the Stribeck Curve, which can be used to chart changes in the coefficient of friction as a function of the Hersey number, which is equal to viscosity x sliding speed/normal load per unit length). Forgive the complexity, but the upshot is that there are three basic states that can describe the relationship between lube and the metal it's been applied to:

- Boundary: this state describes a low speed/high coefficient of friction whereby the lube provides a protective barrier at a molecular level, which is the only thing preventing metal-to-metal contact, and ultimately damage. Think of this is the state of your engine when it is cold - or your drivetrain before you start pedaling.

- Mixed: also known as 'thin film' or 'elasto-hydrodynamic' regime, this is when a thin film of lubricant develops as a result of motion and flow in between the surfaces. Higher speeds lead to greater film thicknesses, which decreases the coefficient of friction to a certain point after which the increased drag of a thicker film increases the CoF (ie. good protection of the moving parts but a lower degree of efficiency).

- Hydrodynamic: the thin film from the mixed state becomes thicker as speed increases, requiring more power input for a given level of output. Put a different way, a purely hydrodynamic state is less efficient and therefore sub-optimal for cycling (and most other applications).

The Stribeck Curve characterizes the relationship between lube and the metal surfaces it's meant to protect, and how that relationship changes based on speed, lube viscosity and normal load (pressure). As the blue line moves to the right, you can chart the coefficient of friction and see that there is a point in the 'mixed' state where it is optimized. The horizontal black lines in the three mini diagrams depict metal surfaces, with the pink/black lines showing the lubricant and the yellow showing the lubricating film that increases in thickness with speed but decreases with increasing normal load (pressure).

Obviously the forces, heat, and friction at play in a bicycle's drivetrain are all lower than, for example, the internal combustion engine in your car, however riding a bike, particularly at serious levels or racing (or even just for enjoyment) requires a high degree of efficiency because humans are weak compared to engines with triple digit horsepower. So, while the position of our drivetrain and lube on the Stribeck Curve at a given time may not feel as impactful on our efficiency, we've also got smaller margins to play with - and I think it's interesting to understand the relationship these factors all have on one another. What is difficult to determine (and I think would make a fascinating study) would be to acquire measurements for positioning on the Stribeck Curve for a given rider (XC vs Trail vs Enduro) in different conditions (mellow vs intense climbing) and performance applications (recreational vs high performance racing). It seems logical that an XC racer would care more about this than a casual all-mountain or DH rider, but there's no arguing that the more efficiently your bike runs, the more enjoyment you'll derive, whether that's based on speed or just efficiency and the ability to ride longer or with less energy needed.

What the Stribeck Curve teaches us is that preserving a Mixed state is important for allowing your chain's lube to do its job. What isn't discussed often is that while preserving that mixed state is not all that difficult, conventional lubes make use of components like PTFE (Polytetrafluoroethylene aka teflon) to achieve it - and PTFE doesn't break down or biodegrade, so it pollutes waterways and other areas, and has been linked to all sorts of health problems in people and animals.

Solvents, Emulsifiers, and Lube

So, you want a lube that achieves and preserves a mixed state, and - like with everything else these days - if we can achieve similar performance with eco-friendly products at similar prices, that's obviously preferable. The challenge is that reaching those performance levels at a reasonable cost creates several extra hurdles to overcome, which explains why bio-based lubes haven't always had the best reputation in the bike world. It's actually very easy to lubricate something - you can use vegetable oil and it lubricates (decreases the CoF) very well, but has other shortcomings. First, regular vegetable oils do not protect the drivetrain very well, and they pick up other contaminants very easily, so your chain will be filthy in no time as the oil attracts dust, dirt, and other stuff you don't want riding shotgun on your drivetrain's componentry. Second, it doesn't wash off easily. This is where emulsifiers come into play.

An emulsion is a mixture of two or more liquids that are normally immiscible (unmixable or unblendable) owing to liquid-liquid phase separation. Lubes use emulsifiers for two key reasons: first, to bind metal surfaces, creating a strong boundary layer as well as preventing wear between metal surfaces and preventing corrosion. Second, since emulsifiers are oily in nature, they also help decrease the CoF. But, because you don't want a lubricant to bond to your metal surfaces indefinitely, you have to be able to control how and when they release that bond (ie. when you want to wash or degrease your chain) and because you don't want that oil bonding with dust and loam. In the same way that soap works on oil, an emulsifier surrounds an oily surfactant in a droplet, allowing it to be washed off. It also can't separate in the bottle (or at least not so much that a little shaking won't fix the issue) - that's a hard-working compound!

WPL has developed specific emulsifier mixtures that are fully bio-based and biodegradable and provide excellent lubricity and anti-wear properties. This is unique to them and lets them lay claim to being both effective and bio-friendly lubes.

The other key material in many lubes is a solvent - used to dissolve an ingredient. Notably, solvents are used to deliver wax onto the chain in a uniform layer, and then designed to evaporate, leaving the wax behind.

A well-oiled chain is essential to an efficient, smooth-running bicycle. But it's also important to consider what happens to that oil when it runs off in the rain or a stream crossing - or when you wash it and that water runs down the drain.

Wet vs Dry Lubes. What should you use and why?

The question of whether to use wet or dry lube is also easily answered, but here once again, understanding the why will shed light on the interaction between your lube and your chain.

Dry lubes are designed to leave a dry film on your chain that prevents dust from building up, and they're usually comprised of a wax and a solvent. The solution is applied to your chain and the solvent evaporates, leaving a dry wax film on the chain.

Wet lubes, which we're far more accustomed to using on the Shore (and in the Pacific Northwest) are designed to repel moisture so it won't wash the lube off the chain prematurely. To do this, they need to be oily and viscous which means they last longer, but also means they are more prone to attract dust and dirt, especially in drier conditions. Dry lubes won't attract that dust and dirt, but they usually do not last as long and need to be refreshed more often.

So, simply put, dry lubes are suited to dry/dusty conditions, and wet lubes in mixed or wet conditions. Each has its advantages and disadvantages. Until recently, a wet lube would work fine all year long on the North Shore, because it may get dusty but the rain usually comes in often enough to dampen things. Not so these last few years! And someone from Whistler or Pemberton would be more likely to have used dry lubes - and even more in these hotter, drier summers we've been having lately.

Most North Shore riders use wet or mixed conditions lubes all year long. Recent hot and dry summers are making a lot of them reconsider whether or not it would be wise to start dabbling in dry lube for certain months.

The importance of bio-based products

Dry lubes typically use paraffin wax, which is derived from petroleum and toxic, especially in the less refined lubricant grades typically used in this application. More refined cosmetic grade paraffins are safer to you, but still have environmental consequences such as not being biodegradable, and are of course more expensive to produce. The solvents used in dry lubes are typically very volatile (VOCs) things like light naphtha, hexane, and 2-methy pentane, among others. Neither are good for you or the planet. And we've already briefly covered PTFE. These are only a few common examples. Just like with ski wax, bike lube comes off and ends up in the ground, eventually washing into streams and eventually lakes or the ocean. It may seem like the amount of chemical contained in your bike's lube is a tiny amount, but consider higher traffic trails or even bike parks with wash stations at the bottom, where hundreds of riders may be hosing off their bikes at the end of a muddy day. All of those chemicals are then swirling down the drain, and they're not being recaptured and disposed of properly. We need to think a bit harder about all our impact in big and small ways.

WPL was keen to partner with us on this 2-Minute Expert because they take environmental consequences seriously, and they're devoted to developing bio-friendly bike products like their Wet and Dry chain lubes. Bio-friendly lubes aren't a new concept, but WPL has made great strides in finding substitutes for petroleum-based ingredients (and others) that still perform well while still being capable of biodegrading. Rather than using isopropanol, hexane or naphtha as solvents, they have found a bio-friendly alternative, such as ethanol. All of their ingredients are derived from plants, either the natural component or derivatives of these natural products, including emulsifiers solvents, polymers, and the oils themselves. They are keeping the actual ingredient(s) close to their chest, but they do publish a list of excluded chemicals - ones they don't use in any of their products - that you could use to cross-reference with other lubes you own when deciding what to buy next.

A Final Word about bio-lubricants and Whistler Performance Lubricants

It is not always easy to engineer natural, earth-friendly products to do the same job that harmful ones do - that is part of the reason we still rely on harmful, petroleum-based products in many facets of our lives: because it can be costly to find alternatives that approach the performance levels of the incumbent. WPL has gone through several iterations of their products. One example is the recent reformulation of their Dry Chain Lube in order to accommodate past issues with clumping of the wax that arose from over-application of the lube onto the chain. The new formula has made it “fool-proof” for users of all experience levels to avoid this clumping issue. The lubricant is also much more durable, and more efficient than the previous version. As with any new product, sometimes it takes one or two generations to get it just right, but the long term payoff, for performance and more importantly the good of the planet, more than justifies the time and effort required to get to get it right.

Comments

Ripbro

2 years, 7 months ago

Haven’t tried the WPL products but I tracked down some dumonde thin lube this year after reading a NSMB article earlier this summer. I’ve been really impressed. Bike is super quiet, it lasts longer than the muc off dry I was using before. I haven’t shown it to my wife yet as she squirts lube on like ketchup on a hot dog… that stuff is too precious.

Reply

fannystackaskill

2 years, 7 months ago

I appreciate the effort in making lubes less toxic. The WD-40 wet lube I've been using has some horrible car-freshener fragrance to it that smells like something the EPA will ban in 20 years. I hate knowing that this shit is dripping off my bike and winding up on the trail, even in small amounts. WPL Forkboost is the only thing that seems to keep my OneUp dropper working properly. Being able to apply it with a finger and not worrying about needing a chemical scrub to avoid accidental ingestion is actually a big selling point, and has made me seek out less toxic sealant and mineral oil hydraulic brakes.

Reply

Timer

2 years, 7 months ago

Sorry for ranting, but worrying about the environmental effects of chain lube seems utterly ridiculous in a sport who's practitioners habitually discard their "made in Vietnam"-carbon bikes after a single season and constantly use multi-ton V8 trucks for shuttling their toys around.

Reply

Martin

2 years, 7 months ago

I really love the WPL products that I've been using! I use ForkBoost to clean my fork, shock and dropper stanchions after a ride and wipe dry after a few pushes. It's perfect to pick up the leftover dust/dirt left after a quick clean, and everything feels super slippery afterwards. I do it religiously after/before a ride and I feel that it keeps dirt out of my lowers as much as possible.

The 15Wt oil is perfect for fork lowers lubrication and is compatible with the WPL grease when the latter is used as a Slickoleum alternative. I was hesitant to use the WPL grease into bearings as it was a bit thin feeling, but this year I've packed a few with it and wow, they roll so much better than with the MucOff grease I was previously using! I'll see after a year how the grease hold up, but I was impressed by the slippery feeling. Next lowers service I'll use it too on my bushings/seals.

The only place where I didn't substitute for WPL products yet is chain lube. I had a few bottles of the old ChainBoost which was too sticky and picked up a lot of grime. It was too messy to use so I gave them to friends to try. This year, I've been amazed by Squirt (which contains no organic solvents, <1% cov, isn't harmful either when reading the MSDS and biodegradable), but I'm curious to try the new WPL dry lube formulation. Squirt stays dry and doesn't pick up any dirt, which means I just run the chain into my mechanical chain cleaner without any liquid just to clean dust and debris. Then I add a drop of Squirt on each link and it dries before my next ride. So easy and clean, I honestly can't see how it could be better. (I have previously been using ProGold chain lube for the last 15 years).

I've always been really cautious with chemical products (I am the kind to read the MSDS before buying any chemical product) and I'm happy to use almost exclusively bio-friendly products for my bikes. (Mineral-oil is mandatory for my brakes too). I already feel bad for driving my car to the trailheads, at least I want to limit my impact in the environment when riding. And now with a kid, I try to limit his exposure to chemicals as much as I can. Thanks to WPL for helping with their awesome eco-friendly products!

Has anyone used Squirt and the new WPL dry lube formulation to see how they compare?

Reply

Niels van Kampenhout

2 years, 7 months ago

+1 for Squirt, have been using it for 13 years now in a wide variety of conditions. Just wipe off dust/dirt after a ride and every once in a while apply new light film of squirt on the links. So easy. I don't see any reason to try anything else to be honest.

Reply

Martin

2 years, 7 months ago

Awesome thanks! Yeah I think I found the holy grail too with Squirt. I bought the 500ml bottle and I'll probably have enough for 5-10 years, but after that, I'll try the WPL dry lube :)

Reply

Flatted-again

2 years, 7 months ago

The only bio-friendly mineral oil I’ve seen is that Bionol that Trickstuff used in their brakes- are there others? I’d love to replace the stuff in my shimano brakes with something less petroleum based

Reply

Cooper Quinn

2 years, 7 months ago

Warning that your seals may not be compatible with other mineral oils.

Reply

Flatted-again

2 years, 7 months ago

Shoot, I thought that the bionol stuff could be used for shimano, Magura, etc. brakes

Reply

Cooper Quinn

2 years, 7 months ago

*may* not.

I can't speak to any combinations specifically. Some of those may very well work just fine!

Reply

colemaneddie

2 years, 7 months ago

I will be reading this article for the headline alone. Bravo.

Reply

trumpstinyhands

2 years, 7 months ago

Whoever is putting that much oil on a chain (in the photos) needs shooting! The amount of oil is way more important than what brand I'm afraid. Too much oil and it just attracts grit / dirt which prematurely wears out the drivetrain. Most of the time my chain is pretty dry, yet it stays clean and after a year it still hasn't hit .5 on the Park CC4 checker.

The informercial above might be useful for roadies who only ride in the dry and care about moar watts, but for mountain bikers, keeping the chain clean is waaaaay more important, especially with parts shortages going on. Want to be environmentally friendly, again don't put half a bottle of lube on your chain ;)

Reply

Deniz Merdano

2 years, 7 months ago

We shot the mechanic that over lubed the chain in the photos. He is buried along with the fella who finger checked his tire pressure before every ride...

Joking aside, there is no good way of photographing lubing the chain unless there is some drama. The exaggeration helps with the illustration. I hope you recover from this mental scar..

On a side note, i am a T9 user myself. My chain never ever needs cleaning..

Reply

trumpstinyhands

2 years, 7 months ago

Good to know. I hope it was a long and horrific death :D

Reply

Nico

2 years, 7 months ago

Using T9 myself without issue and have loved the clean drivetrain. Recently, a wet bike pack trip which included all-day rain and numerous stream crossing+cow shit and mud necessitated the use of finish line wet lube for a few days. Can’t wait go back to T9, but am curious to try out WPL’s enviro conscious and performance lubes.

Reply

mvigers

2 years, 7 months ago

I'm happy to be told U'm wrong, but I don't believe bike chain lubricants are anywhere close to a mixed-regime, and are instead always in a boundary regime. For sure, suspension oils will be in mixed and hydrodynamic regimes, but chains are very very different as far as speeds are concerned.

For the Hersey number, the speed is the speed at which the pin is rotating against the roller. I think this should be somewhere on the order of 0.01m/s (this assumes the link is rotating at one full rotation/s)

The dynamic viscosity is a difficult parameter to estimate, especially when dealing with solid additives in lubes, but for the sake of argument, assume you are using WPLs 2.5wt suspension oil. The viscosity will be ~0.02Pa*s

With these two numbers, to enter the mixed regime (lambda=1.2) the load would need to be less than 0.001N/m. Now, I don't have the biggest legs out there, but even I am putting significantly more load onto the chain than that.

So my question is this, is the Hersey number even worth considering when thinking about chain lube, or are there far more important considerations to be accounted for?

Reply

Cee Cee

2 years, 7 months ago

This poor fellow tested lubes for three weeks and was criticized in the comments: https://www.youtube.com/watch?v=FbFNrnQ4QUo. WPL is biobased, but can I drink it? In future, will our choices be soybean, olive, lanolin, snake?

"UNI-ABIL has licensed 16 formulated lubricants, greases and base oils made of high oleic soybeans that have been genetically enhanced for stability. These products meet and exceed industry requirements, and many do not cost much more than their petroleum counterparts. If these products can compete in performance and price, their environmental benefits will make them even more appealing to users.

Products currently available from soybean oils include: tractor transmission hydraulic fluid, industrial hydraulic fluids for process and machinery applications, food-grade hydraulic fluids and greases, greases for use in automotive, railroad and machinery applications, chainsaw bar oil, gear lubes, compressor oil, and transformer and transmission line cooling fluids. Currently, field tests are continuing on two-cycle engine oils, metalworking fluids and other specialty lubricants."

Multitasking doomsday preppers want to know

Reply

Mark

2 years, 7 months ago

This article took much longer than 2 minutes to read. Who can I send the bill too for my unanticipated time loss?

Reply

Please log in to leave a comment.