Editorial

Behind the Brand: Chromag Bikes

Originally posted 2018-06-27

Imagine landing in a position where you’re the head of a respected brand without planning for it… In a sense, it’s how Chromag was formed, but on the flip-side, not at all. Ian Ritz, the founder and owner of Chromag Bikes, had always wanted to design a well thought out frame but admits he had no idea the brand would end up as successful as it is today.

In 2002, Ian was part owner of the Evolution bike and ski store in Whistler. His role with the store and involvement with the tight-knit riding community ignited an interest in developing a hardtail. Dual suspension bikes were problematic back then and some local riders were looking for a simple, low maintenance bike that could take the beat-downs.

Through a turn of fate, Ian met Mike Truelove via Bruce Spicer (of Brodie Bikes). Truelove told Ian he wasn’t a designer, but he could build a bike if given the numbers. Ian was living in a shared house of diehard riders, including Tyler Morland, former DH racer and now Brand Manager at SRAM. Housemates and shop staff from Evolution began to gather frames they liked and together they proceeded to measure every last millimetre — on the kitchen table. The measurements were discussed and eventually a 1:1 scale mockup was hand drawn and passed over to Truelove. That drawing became the first Chromag frame and Ian’s personal bike. It led to the TRL model, a frame that evolved and remained in the line until 2012.

You know, I’d like to make a frame someday and call it a Chromag… – Ian Ritz

The first Chromag product ever, the TRL (on the right) was Ian's personal bike.

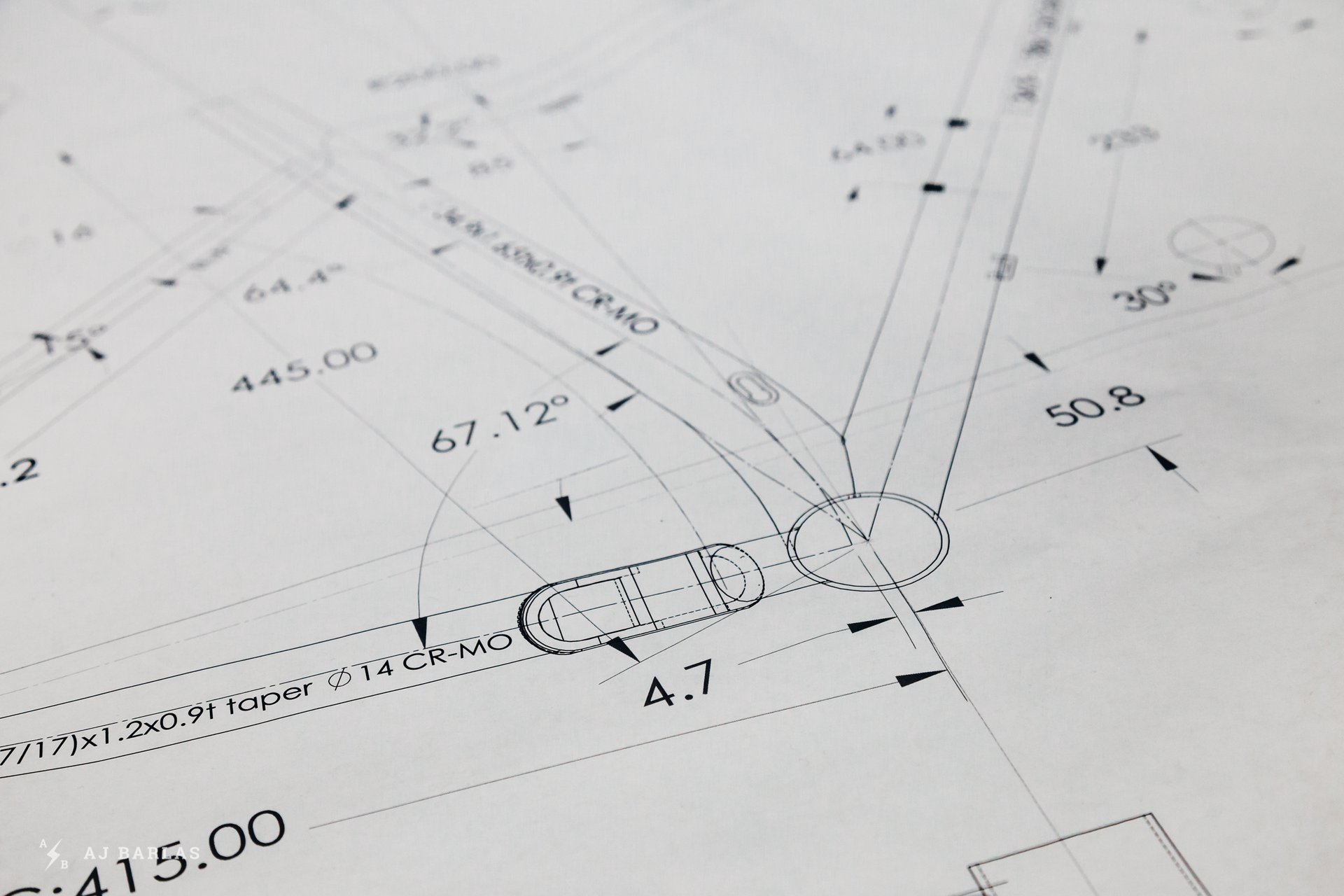

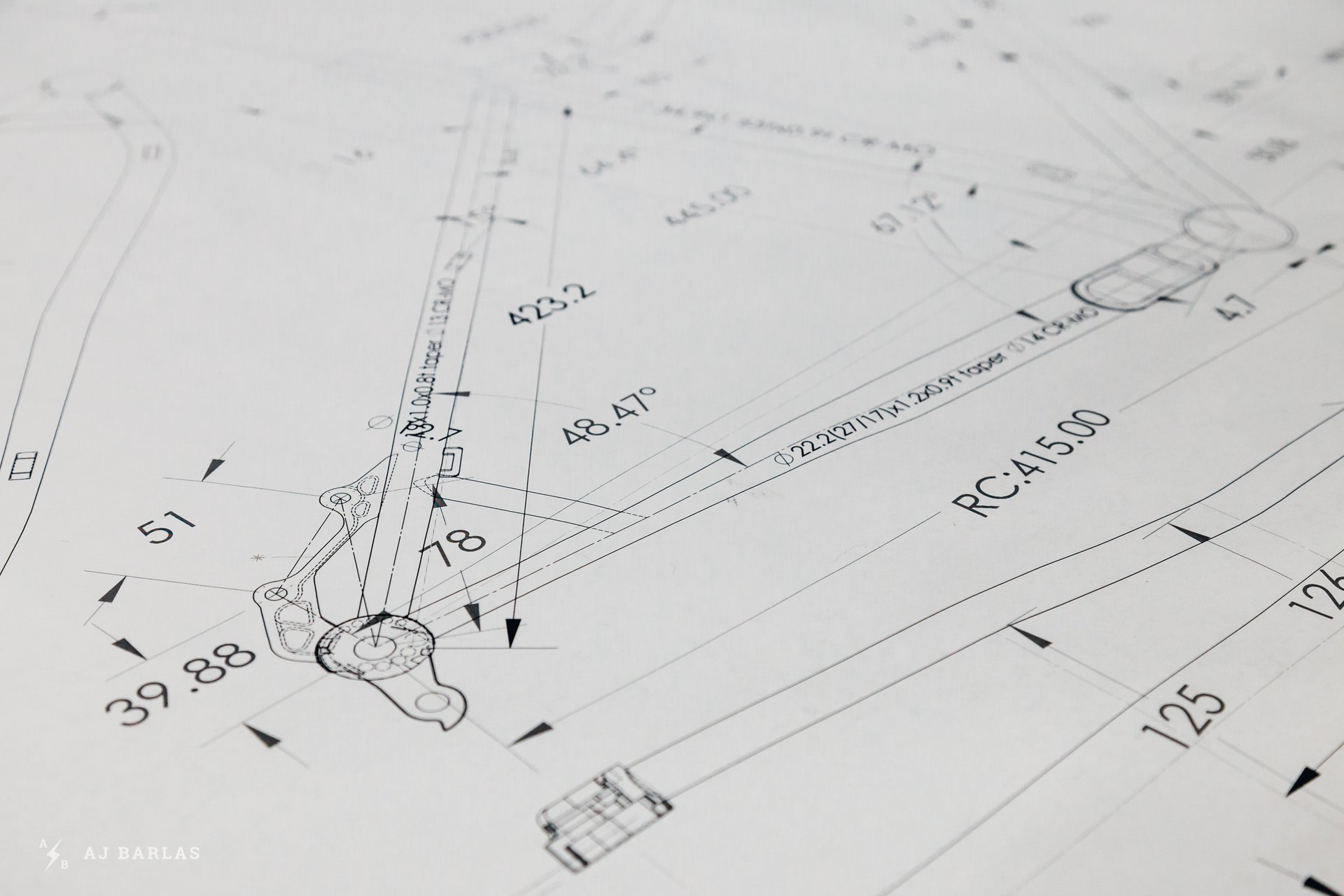

Chromag's first frame was drawn up at a 1:1 scale…

They're still doing it to this day, but now with help from a computer.

The excitement was high and immediately Ian had the interest of the local riding community — which isn’t surprising considering the demand for that first locally made steel hardtail. Eight TRL frames were made during the 12 months following, and another eight the following year. But Ian was still working full-time operating Evolution. That was until August 2003, a little more than a year after tackling the first frame, when Ian sold his share of Evolution and incorporated Chromag Bikes days later.

It sounds pretty well planned, hey? However, despite his desires and the demand, Ian admits he incorporated the business on a whim after selling his part in the shop. He also openly admits that he had no plans to expand as far as it has today and there was no business plan, which he confesses is the wrong way to start a business.

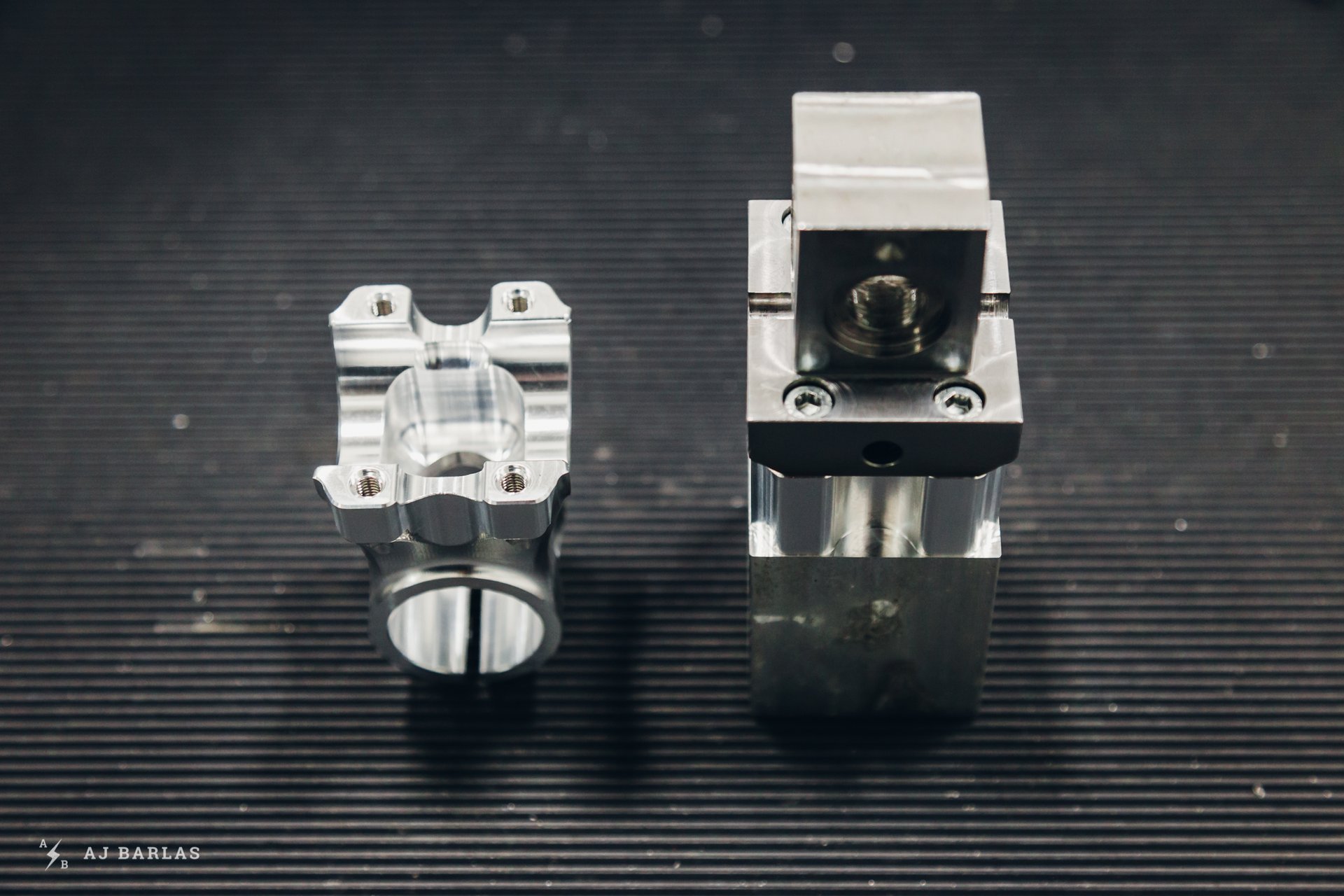

Chromag has always focused on the small details. Their dropouts and hangers show this and are works of art.

An early through-axle dropout.

Prototype dropouts with drillings to try and save weight.

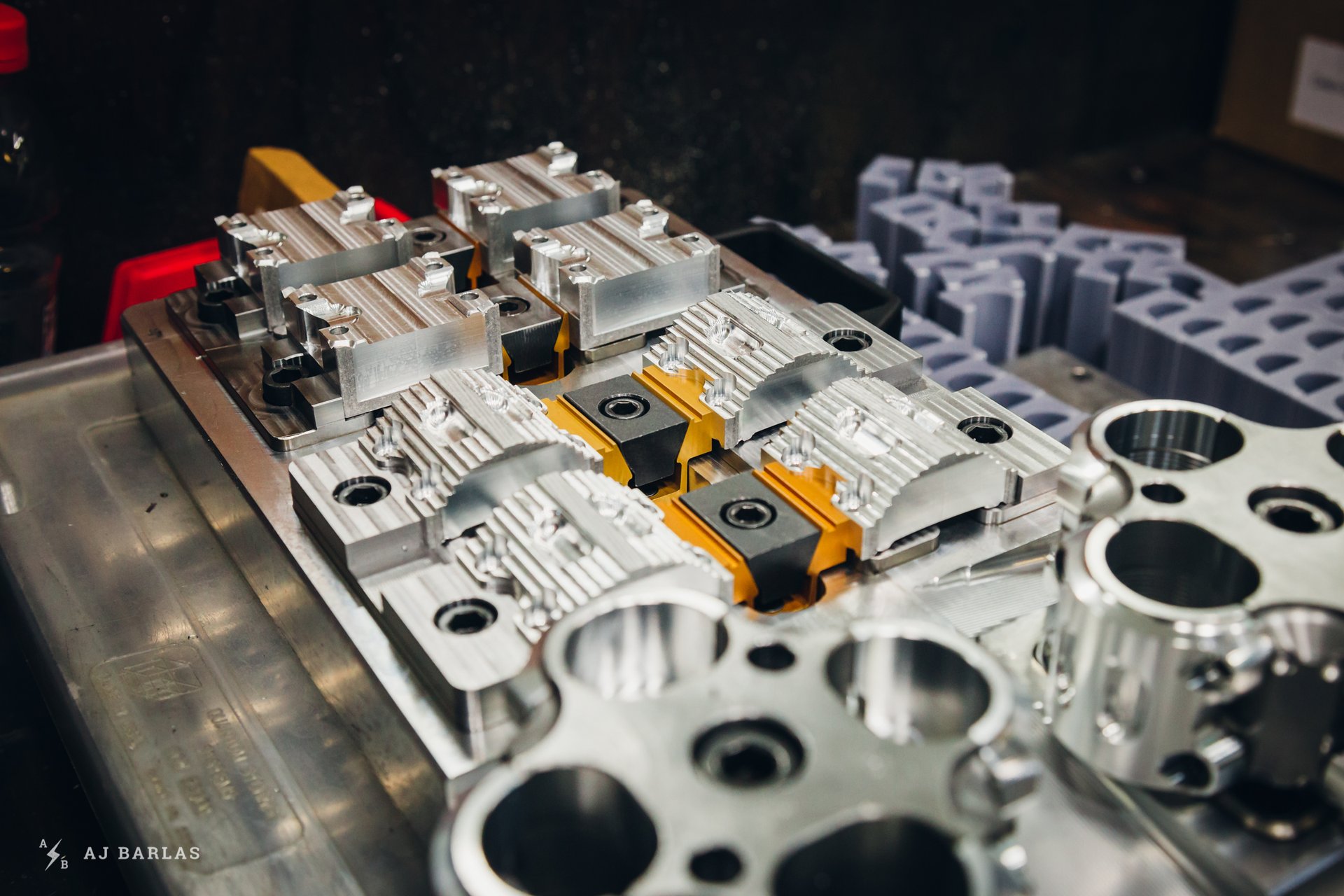

The brake mounts, like the dropouts and hangers, are manufactured two doors down at North Shore Billet.

Chromag's wishbone pieces and the brake bosses, also machined at NSB.

Chromag's dropouts are machined on these plates.

An original TRL badge and gussets. Lessons were learnt from these early designs.

Eventually, Ian found that he’d gotten so deep into the investment that he had to make a serious go of it. Crunching the numbers, it became clear that he couldn’t make a living from frames alone. Chromag needed to expand beyond the hardtail frame niche. With industry experience from years of trade shows as an independent retailer, Ian began looking into suppliers to manufacture Chromag components.

Chris and Pete, the founders of North Shore Billet, had also started their business around this time. A collaboration between the three began and Chromag’s first stem, the Softblock, was released in 2004. The colourful era of the late 90’s had ended and the industry had reverted back to black components, a move that Ian found boring. The stem and bars Chromag produced added a splash of colour back into the sport but performance was there as well. Durability remained key and Ian notes that he wanted to make an unbreakable stem after seeing others bend and twist under local riders.

Chromag's stems have come a long way. The BZA is their most refined to date.

Cockpit components began the breakout but it was a simple seat clamp that captured the attention of a global audience. Quick-release seat clamps at the time were shitty, often using a thin alloy shim that the lever ran against and eventually destroyed. In 2011 Chromag’s seat post clamp, which includes a piece of brass to improve functionality and durability, was included in the Dirt 100, elevating their profile.

Another product that played a pivotal role in Chromag’s early growth was their direct mount stem for the RockShox Boxxer. Tyler Morland, housemate and close friend of Ian’s, had just started at RockShox. Ian learned of a new direct mount standard and they began discussing a stem for the Boxxer using the new mount. Initially, five were made and fit to the bikes of high-profile RockShox athletes, including Sam Hill and Nathan Rennie. This was before 31.8 clamp diameters existed* and the bore of the stem was designed to work with 25.4 bars. With no time to anodize them, the stems were handed out in their raw alloy form.

*When Chromag first released their 31.8 bar, the Fubar OS, it was considered ’oversized’

Up to this point, everything was resting on Ian’s shoulders. He was still operating Chromag from his living room in Whistler and the brand began to grow, fast. Setting up the home office once his partner, Rebecca, headed to work only to neatly pack everything away before her return was getting old too. In 2008 Ian took the next step. A small warehouse space in Function Junction opened up and Chromag moved in. That modest location is only a short walk from their current base. For the first 12 months at the Function location, Ian continued to work alone but in 2009 his neighbour and friend, Julian Hine, started as the first employee. Julian’s primary role was in sales, an area he had experience in, and it allowed Ian to focus on product design.

The Chromag Ranger stem. A product that when first released pushed the brand's aesthetics into the future.

Design Aesthetics

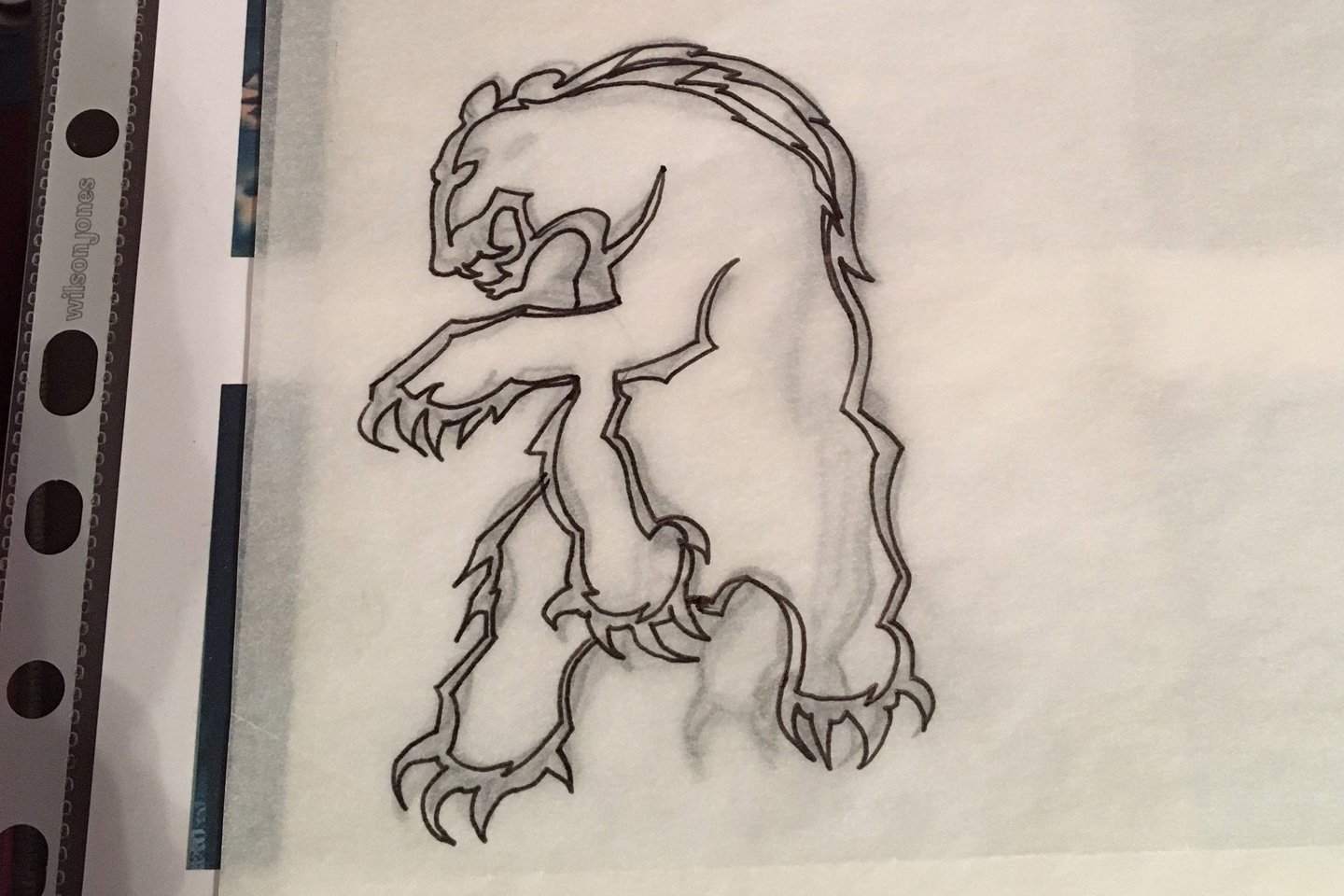

Chromag’s products and branding have always been distinctive and original. From the now legendary bear icon that Ian’s artist mother drew, to clean geometric lines in the graphics, smooth stem edges and intricately detailed frame dropouts, Chromag has paved its own aesthetic path. Durability has always been a goal, but Ian wanted something that he and his friends were stoked to run on their bikes. As time goes on the look has evolved but the goals remain the same.

I wasn't surprised to learn that Ian’s late mother was an artist. It made sense when observing the brand and from the little I know the man himself. Look at any Chromag-hosted event — things like the annual Show & Shine — and you’ll notice an artistic flair there too. Ian’s sister is also an artist and she painted the Chromag lanterns featured at the Show & Shine.

Ian and Rebecca recently discovered the original Chromag Bear drawing crafted by Ian's late mother, Kathy Long, when visiting home during the winter of 2017. Photo: Rebecca Ritz

Ian’s artistic side has helped steer the brand and set it apart. It’s drawn similar creatives, like the Coastal Crew and Brandon Semenuk, and further cemented Chromag's stature in the industry.

Chromag's product evolution parallels Ian’s own growth and the first Ranger stem is a good example. The Softblock, Cutblock and direct mount stem each had a similar look but when Ian was designing the Ranger he had become more proficient working with CAD in 3D, resulting in a more detailed and finely tuned design. And yet it still fits perfectly in the Chromag range; it displays rounded edges and corners, and geometric lines in the laser etched graphics.

Chromag's CNC machined stems are manufactured by North Shore Billet, just two doors down from their Function Junction HQ in Whistler

A Ranger stem mid-production. This stem signifies when Ian's CAD skills lept ahead. The current version (pictured) has been refined more.

Ian is still deeply involved in the look and feel of Chromag, but as the brand expands, so does his team. He now oversees the graphics, which are produced by former World Cup DH racer and longtime Whistler resident, Claire Buchar. Handing over the visuals of the brand was hard for Ian. The look is integral to the brand’s success and what they stand for. Buchar started in sales but Ian was aware of her artistic side thanks to their days together at Evolution. Today, he’s incredibly thankful for her help and the work she does.

Claire is tasked with upholding Chromag's visual sense, something that Ian says is heavily rooted in Chromag's success. No pressure, Claire!

Chromag’s growth meant product design had to expand as well. Reliable, high-performance parts remain a focus, but Ian felt it was time to go deeper and push product development further than he's able to on his own. Ben Arnott, mechanic for the YT Mob alongside Aaron Gwin’s personal wrench, John Hall, has the experience needed. Since autumn 2017, when Ben’s not galavanting around the globe wrenching on race bikes, he’s helping Ian design the latest Chromag products.

I’d be an idiot not to mention the influence of music on the Chromag staff. Music is a passion that permeates the workspace and Ian admits that it's an integral part of his design work and life. Upstairs, in the back of Chromag HQ is a jam room with drums, an assortment of percussion instruments, and speakers… let’s not forget the speakers. They're an element that Chromag hasn’t been shy to show and speakers have been a part of the brand’s image for some time now.

Some pretty major jam sessions go down in this space.

To explain the speaker obsession, Ian points out Chromag's proximity to Whistler’s Re-Use-It Centre, a location where people can drop off unwanted items, or purchase something second-hand. It’s like a thrift store, but being in Whistler, there are often incredible finds. When dropping off rubbish, staff would stumble across speakers in various states of repair and they began hoofing them back to the office.

Ian and Rebecca surrounded by a small selection of the speakers that litter the building.

Over time, friends and fans saw what was going on and would randomly drop off finds of their own. The last time I was in the old space there seemed to be more speakers than bike parts! Their new, larger space balances it more, but there remains an abundance of speakers – some functional, some not – strewn about the building. Their interest in music has additional benefits. When fitting out the current location, Cookie — Chromag’s third employee — had his sound engineer friend Irv, wire the building for integrated sound — everything from different segments, volume, etc. throughout the entire space. Chromag doesn’t mess around with their music…

Art, in musical and visual form, has had a clear influence on brand's visual identity.

Not all speakers are created equal… Julian's boombox.

The Friday Ride

Every good riding scene across the world has some form of a hub and in 1998 a new one in Whistler started. Before Chromag existed, Ian and a group of friends had Friday’s off. They would get together, have a massive breakfast somewhere, hit the trails for the day, then follow up with some beverages. Over time more friends began setting their schedules to have Fridays off for the ride. Years on and with Chromag firmly established, the Friday ride has become an institution.

The ride has become a staple for Ian and many Chromag staff. They operate on a four day week, dedicating Friday to riding bikes. They’re a brand that honestly lives and breathes mountain bikes. Dedicating a day of the week to riding is special and there aren’t many in the industry able to say that they have something similar*.

*Some involved in the industry will tell you they ride less now and work more than they did prior to working within MTB

For Chromag, the Friday Rides reflect the brand's soul but the Show & Shine is the chance for owners to show off, and Chromag’s chance to throw a big party to celebrate and thank everyone that supports them.

Riding bikes is important.

Starting more by accident, the Show & Shine was actually the idea of Ian’s old housemate, Tyler Morland and part of an early SRAM Loonie Race. A day before the event Tyler mentioned the Chromag Show & Shine idea to Ian, and they jumped on it. Since then the Show & Shine has grown more involved every year, with riders and participants putting an incredible amount of time and effort into their bike builds and displays.

Thirteen years on, the Show & Shine is one of the biggest summer events, drawing participants, racers, and loiterers from far and wide. There are generally between 50 and 70 bikes submitted to the show and it’s a spectacle that visitors to Whistler often make a point of checking out. The Show & Shine combines many of the elements that are important to Ian and the brand: riding bikes, music, food, and a powerful social scene, but being able to show his gratitude and spend time with supporters and friends of the brand is foremost.

It’s such a personal thing, a bike. It’s an extension of you that gives you super-powers… It’s a real source of pride for people and feeling part of the club is something that people are drawn to. – Ian Ritz

Chromag's titanium Surface…

It would definitely give you super-powers.

Thanks, Whistler

The social aspect of riding and its importance to Ian and Chromag can’t be underestimated. When asked about Whistler’s influence on the brand, Ian quickly responds; “I don’t think I could have done it in any other place — the community is so supportive.” It’s clear Ian is a big fan of where he lives and the people of the community, and he’s not afraid to give credit where it’s due. This side of the Show & Shine is one that observers may not catch. Yes, it’s a big party with a lot of food and music, but for Ian and Chromag, it’s a great way to thank their supporters.

Chromag continues to grow, adding more skill to the list of employees along the way. In autumn 2017 they grew to 15 employees and continue to work with local frame manufacturers Mike Truelove and Chris Dekerf, who each have their own models that they focus on. They take advantage of opportunities to connect with cycling enthusiasts from all over the world, unmatched thanks to the mountain bike mecca that Whistler is. The idea for a name that “had a nice ring to it” is now a big brand, with Ian and everyone else at Chromag striving toward bigger and better.

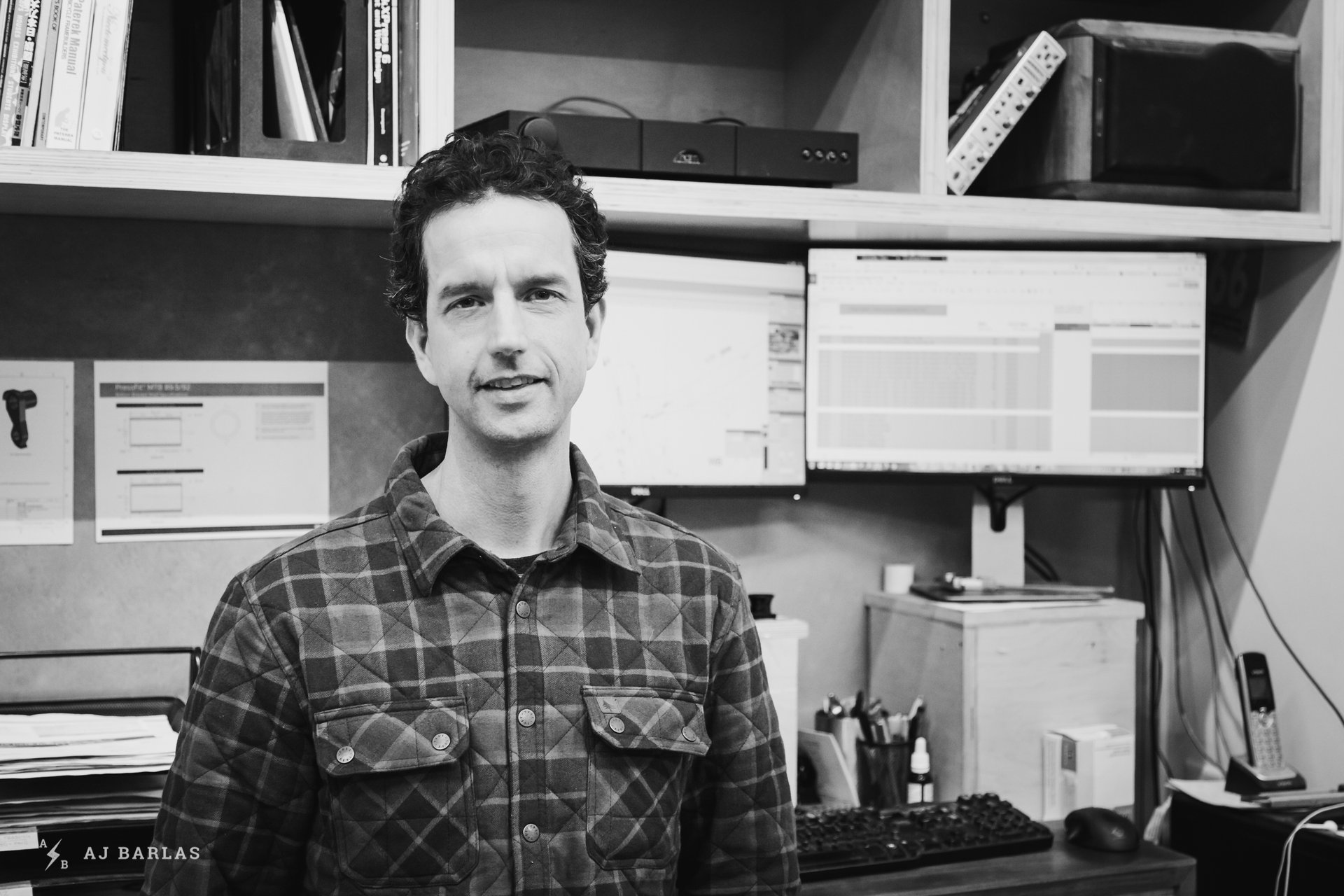

Ian Ritz – Chromag Founder

Ian is a huge music and design fan

Julian Hine – Sales and Chromag's first employee in 2009

Julian DJs as a side hustle because it's "fun as hell".

Cookie Losee – Warehouse Manager

Has played music professionally for 33 years. Plays bass guitar, keyboard, trumpet and more. He's responsible for the jam room and massive stereo systems at Chromag. Photo: Rebecca Ritz

Sean Dinwoodie – Sales & OEM Manager

Continues to ski like a madman in the winter and teaches skiing on Blackcomb on his weekends.

Claire Buchar – Graphic Design

Also a coach and athlete/brand ambassador for Intense Cycles, Fox Head, and a number of other key brands. Claire was a top 10 DH World Cup racer for a number of years

D'Arcy Burke – Mechanic

In the winter he's the grooming supervisor on Whistler and skis a lot of pow. His summers are spent wrenching on bikes and maintaining his own bike trails. Photo: Rebecca Ritz

Pete Fowler – Mechanic

Pete's a "home shop tinkerer". He bought his own manual milling machine and a lathe just for kicks

Matty Richard – Warehouse & Assembly

A professional skier filming big mountain lines for movies. He surfs in Tofino and adventures on his dirt bike too. Photo: Rebecca Ritz

Rebecca Ritz – Marketing & Photography

Passionate photographer and a big ski/snowboard fan

JM – Warehouse & Online Store Manager

A basketball fanatic, and he's from Belgium…

Emilie de Crombrugghe – Operations Manager

Spends her winter weekends teaching skiing/snowboarding and her summers adventuring. Photo: Rebecca Ritz

Seb Bunney – Inside Sales

Mountains! A love for all sports mountain related, along with a huge appreciation for the financial markets and investing. Photo: Rebecca Ritz

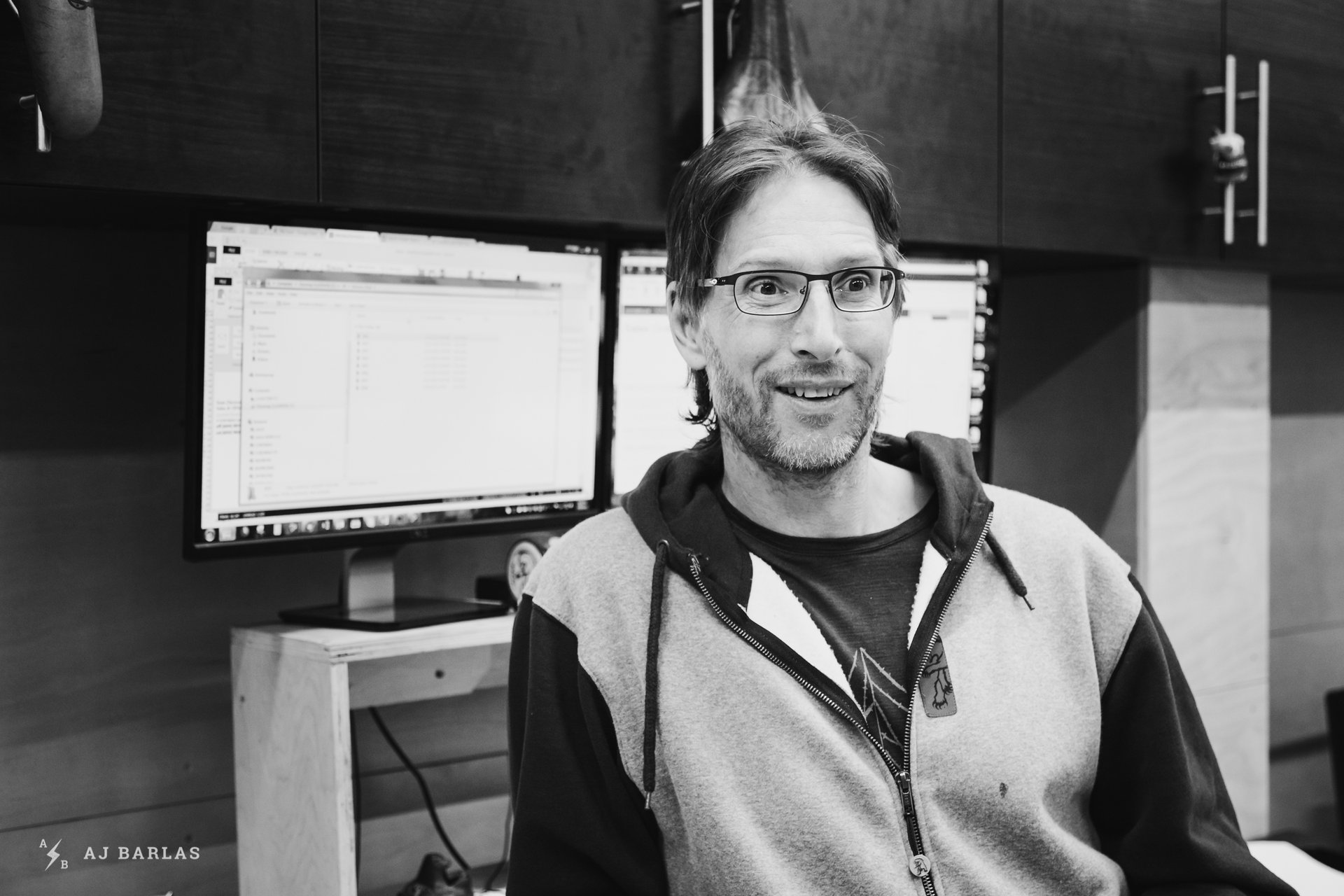

Ben Arnott – Product Development Coordinator

Ben is also the partner in Alba Distribution and wrenches for the YT Mob

Matt Cooper – Sales

Matt is also a partner in Alba Distribution and snowboards on Whistler, because "it's the better mountain"

Will Westwood – Graphic & Product Design

Spends time on a BMX as well. Plays the drums and is a keen snowboarder/splitboarder. Photo: Rebecca Ritz

The Future

Before finishing the interview I had to ask Ian about a product that was surrounded with rumours for years. A product we’re yet to see from Chromag; a steel dual suspension frame. There is one in existence — it’s the garbage runner — and it took in excess of three years to complete. By the time they had it finished, Ian wanted to change everything about — such is the life of a creative at times.

Chromag's steel dual suspension. The bike is still ridden regularly, as the garbage run machine. One day we'll see a production Chromag dual suspension, it's a matter of time.

Ian notes that while they appear to ride hardtails exclusively, they aren’t zealots, and they realize today's dual suspension bikes are incredible. Ian points out however that the day he owns a dually, it will be emblazoned with a Chromag badge. We discuss current steel dual suspension manufacturers and it’s clear that it excites Ian, but he struggles because of how badly he wants to make one himself.

Unfortunately for fans, a dual suspension isn’t on the horizon yet. Chromag will continue to focus on other new and exciting projects, both in terms of hardtail frames and components. Expect the same attention to detail Chromag has become renowned for, but with more focus on progression. If they continue along this path it can only mean great things for fans the world over.

Comments

Perry Schebel

5 years, 9 months ago

great piece, aj! cool company; larger (relatively speaking) than i had expected. and: a MT or dekerf built chromag dually would be sick. with a fillet brazed option of course. one can dream.

Reply

AJ Barlas

5 years, 9 months ago

Thanks, Perry. Glad you enjoyed the read. They've expanded a lot very recently. Mmmmmm, a fillet brazed dually – that's stepping it up a notch!

Reply

fartymarty

5 years, 9 months ago

mmm a Chromag full bouncer. Now that would be awesome. Something simple like a Starling.

Reply

Shoreboy

5 years, 9 months ago

Not sure a Starling would be a comparison I would strive for given its last review.

Reply

Perry Schebel

5 years, 9 months ago

we just happen to have a starling in the NSMB review fleet right now. current perspective is positive.

Reply

Shoreboy

5 years, 9 months ago

I look forward to the second opinion!

Andrew Major

5 years, 9 months ago

Yes, this was a great read AJ!

Reply

FlipSide

5 years, 9 months ago

Excellent article! Seems like the best company to work for.

Yes, a dually would be great...and a lighter steel hardtail frame option would also be amazing! I am thinking about a modern 29er Kamui or something along those lines.

Reply

IslandLife

5 years, 9 months ago

Now this is a company... they get all my component money. Just wish they'd hurry up with that FS already!! :-)

Reply

pedalhound

5 years, 9 months ago

I just picked up a Rootdown last weekend...currently the long slow process of getting it built up and it's killing me. I just want to ride it! I have been a fan of Chromag for many years, running their components on many different bikes....love their style. Now...if they could build a nice fully...that would be a dream!

Reply

AJ Barlas

5 years, 9 months ago

It certainly sounds like a full suspension Chromag would sell like hotcakes! Seeing the original push was partly demand, perhaps everyone can make enough noise ensuring it happens?

Reply

Peter Leeds

5 years, 9 months ago

I just recently bought a Chromag Surface Ti, and have it built up and have put 3 rides on it, and it is better than expected. There is something about a Chromag that transcends simple material.....it rides in a way nothing else does. You can tell it has soul. And I have had boutique bikes for 20 years and know what to expect....it is all in the details. Yes, some will say they are expensive, for a hardtail, but quality costs money and believe me you get what you pay for. If only I could find a way to not have to work and ride every day....working on it......

Reply

JVP

5 years, 9 months ago

Love seeing stories about local companies in the Northwest (or probably Southwest to you guys up there). Brands forged by the needs of abusive riders are the best. I lust after those ti frames.

Reply

Endur-Bro

5 years, 9 months ago

So is Alba Distributors based out of Chromag?

Reply

AJ Barlas

5 years, 3 months ago

Nah, they just ended up with two of the guys behind it working for them.

Reply

Nouseforaname

5 years, 3 months ago

Last time i was up in Whistler - that priceless prototype full bouncer was lying neglected in the parking lot and Chromag were closed. LOL. Literally just lying in the mud.

Reply

Mammal

5 years, 3 months ago

Man, I'd take it off their hands... We have an aggressive parts bath and large powder coating facility at my work place;)

Reply

kekoa

5 years, 3 months ago

On an off day and in search of omiyagi my band of merry Hawaiians and I stopped by (I think we had to take a blown rear shock to Vorsprung). Found the staff to be extremely welcoming and friendly. We bought shirts and stickers and socks an even got to try the pivoting deth machine in the parking lot. Was a highlight of the trip!

Reply

AJ Barlas

5 years, 3 months ago

Glad you survived the pivot to talk about it! Haha.

Reply

RV

5 years, 3 months ago

Awesome article!

Reply

AverageAdventurer

5 years, 3 months ago

Top notch article! I built up a samurai a few years ago and had it painted up all fancy. My all time favorite bike, no matter what I ride nothing gets me jacked to ride like that does. They're local and awesome to deal with.

Reply

Noel Dolotallas

4 years, 5 months ago

Great article! Love these pieces about founders and what they went through. So much back story we 'regular folk' dont get to hear about.

Reply

Please log in to leave a comment.