Transition’s new DH Proto

The Transition TR450 is designed as a dedicated downhill racing machine. Factory rider Lars Sternberg, along with other select riders, will be rallying the frame all season. Transition expects production models to be ready sometime early winter 2009 for the 2010 race season.

The TR450 is currently in prototype testing, so geometry and other features are not finalized, and may still change by production. The prototype frames feature a 64 degree head angle, 14” bottom bracket height and 17.5” chainstay length. Three sizes are being tested with wheelbase lengths of 45.5”, 46.5” and 47.5” for the small, medium and large frames. Heavily researched and selected with direct input from Lars, this is an aggressive geo built for speed and stability. With a careful ratio between chainstay length and head angle, the frame has a neutral feel in corners with good rider weight balance between the front and rear wheels.

The TR450 gets 8.25” of travel from a 9.5” x 3” shock placed low in the front triangle. The linkage was tuned to provide a gradual change from beginning to ending leverage rate. The 2.75 to 1 average leverage rate makes shock tuning easy and keeps stress on the frame low.

“It was pretty important from the get-go that we really get the leverage rate curve spot on with this frame. The overall curve has a pretty linear rate of change so the leverage rate does not vary wildly through the travel. The suspension ramps up very evenly through the travel to give the bike a supple top stroke and good bottom out control without excessive sag or mid stroke wallow. This result in a consistent progressive suspension feel that is predictable and yields a high amount of tunability,” said Kyle Young of Transition Bikes.

There are large cartridge bearings at all pivot locations, with an absolute monster of a bearing used at the main pivot for durability and frame stiffness. All bearings are pressed directly against machined bearing seats inside the linkages, eliminating misalignment that can occur when bearings placed at outer edges are “pinched” together. The overall suspension design was selected to keep the shock low in the frame, while still protecting the rear shock from tire roost. The pivot points have been laid out to triangulate loads and keep the rear end stiff, which helps keep the bearings turning smoothly, and your wheels tracking straight.

Custom tube shapes were developed and the downtube has a tooled reinforcement rather than a traditional weld on gusset. This thicker section reinforces the underside of the downtube/headtube junction without the stress riser created at the edge of a weld on gusset. The front triangle features double welding, which creates a thick but smooth weld and yeilds a significant increase in strength for high stress areas. The TR450 has a tapered headtube with an integrated Cane Creek size top bearing and standard 1.5” bottom intended to run a zero stack cup. The shape of the headtube better matches the toptube and downtube size and shape, and leaves plenty of clearance for fork crowns. The short headtube length gives riders lots of room for handlebar height adjustment and an aggressive low stance.

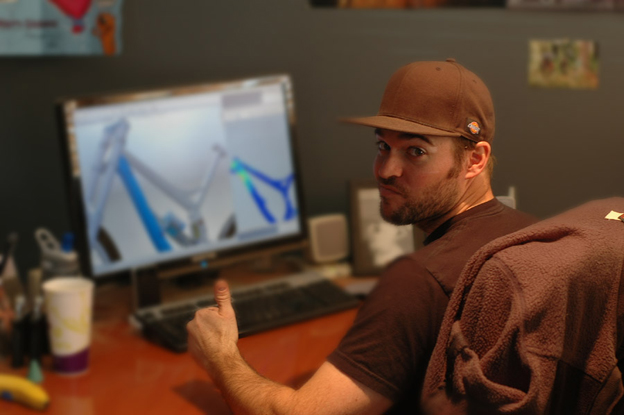

“When developing the overall look of the bike, we wanted to avoid visual dead ends. All the lines on the bike flow together; the line of the downtube flows into the chainstay, the top tube flows into the front triangle uprights, and the shock sits relatively parallel to the top tube and seatstays,” said Sam Burkhardt or Transition Bikes. “The custom tubeset was designed for strength and stiffness in key areas; such as the headtube, shock mount and bottom bracket. The result is a modern, but subtle tube shape that does not distract from the classic good looks of the bike.”

Mud shedding was a key concern in the design of the frame. Excessive pockets were avoided and many parts, like the dropouts and rear triangle yokes, are hollowed from the inside and smooth on the outside so mud won’t collect in hard to reach places. The smooth aesthetic carries over into the lines of the frame. When viewed from the side, the linkage stays hidden from view right up to the sag point. This is a clean frame, any way you look at it.

“We set out to design a bike that could be ridden hard and put away wet. We know how frustrating it is to skip a ride waiting for proprietary parts or a complicated overhaul, so we built a bike that was reliable and easy to maintain. This is a top level race bike that doesn’t require a full time mechanic to keep it running,” said Sam Burkhardt “Being from the Northwest we ride in all conditions and expect our bikes to spend more time on the trail than in the shop.”

Transition was not setting out to create an ultra light fragile pro-only frame; this is intended to be a dependable bike that riders can trust race after race. That being said, the TR450 frame is not an overbuilt tank either. The painted medium prototype frame weighs in at a respectable 11.6 pounds with a DHX RC4 (with steel spring), aluminum rear axle and all frame hardware. Lars’ complete bike weighs in at 39.5 pounds as pictured here. Retail pricing has not been announced, but customers should expect a great value with amazing performance for the price.

Keep an eye on transitionbikes.com for more updates on the TR450 as testing continues. For more info check out the video below to watch the build and Lars hit the trail for the first time on the Transition TR450.

This is one of the nicer looking DH bikes i’ve seen in some time. What do the armchair experts think? Opine freely here…

Comments

Please log in to leave a comment.