First Impressions

WTB HTZ i30 eMTB wheels

Hefty alloys for the E's

WTB has introduced a new alloy wheelset - HTZ i30 - aimed at eMTB riders looking for a strong and beefy set of wheels (mountain bikers can enjoy them too, just check the weight first though). l I received the wheels a few days ago and then mounted them onto my Norco Range VLT. I proceeded to pedal up the road to meet my shuttling friends for a top to bottom lap and again up the road for another top to bottom lap. After 20 km of road climbs the wheels went through high speed loam, fast chunder, fireroad descents, a flow trail, a janky OG trail and one we call 100 pushups for its massive number of high speed bumpy hits. Did I notice the wheels? Honestly, no. Do I feel more confident on these wheels than my current very used DT Swiss E 1700s that could use some spoke tightening to true my aim and hold my edge in corners? I think so. The first impressions can also be called first and only ride impressions as that was my only ride. To me, how a wheel performs is all about longevity. Can I avoid denting and breaking them and walking out of the trail and then having to buy/warranty a new one and source spokes then build it with my weak building skills? My other thoughts are all about what these wheels are made of and why.

My HTZs came with Verdict rubber already mounted.

When I look at what parts are the important for my ride, I focus on brakes and suspension but what I am drawn to most is a nice set of wheels. I don't think they are as important as brakes and suspension or even a good dropper, saddle and pedals but boy do they look good when they are new and shiny.

Deniz posed this question about wheels in his Reserve 30 review:

Where do wheels fall when it comes to the importance hierarchy on the bike? Are they the legs of the bike? The Feet? Maybe the brain? Because it doesn't matter how good they are as long as you have some?

Deniz had some good wisdom saying that wheels are the cerebellum of the bike. Getting things done instinctively in a lightning fast manner without the need for constant attention. That will have to be tested over the long term. In the meantime, here's some info about the wheels and some nice photos.

The first thing I noticed when I got the wheels was the stylish square, wide look to them. Then I picked them up and wow - they are portly. Claimed combined weight is 2662 grams. That's a french fry away from 5 pounds. My test set came with a set of Verdicts at 1257g per tire; all in, tires and wheels are about 11.5 pounds. But I guess when it comes to E bikes extra weight is just another log on the fire. Actually, I did notice that I sweat 7 drops of sweat instead of 4 on the climb with the extra weight.

The HTZ130s are made of aluminum which means saves cash compared to carbon. At about a thousand CAD for the WTBs versus a comparable carbon set like We Are One Strife DH at 1675 CAD, that is a significant difference in price. I will leave the alloy vs carbon value argument to the commenters because there are so many alloy owners with no breaks and dents and so many carbon owners with broken wheels it is hard to win that fight.

The front wheel. Note the tape. WTB uses a nylon strip under their rim tape called Solidstrip. Photo WTB.

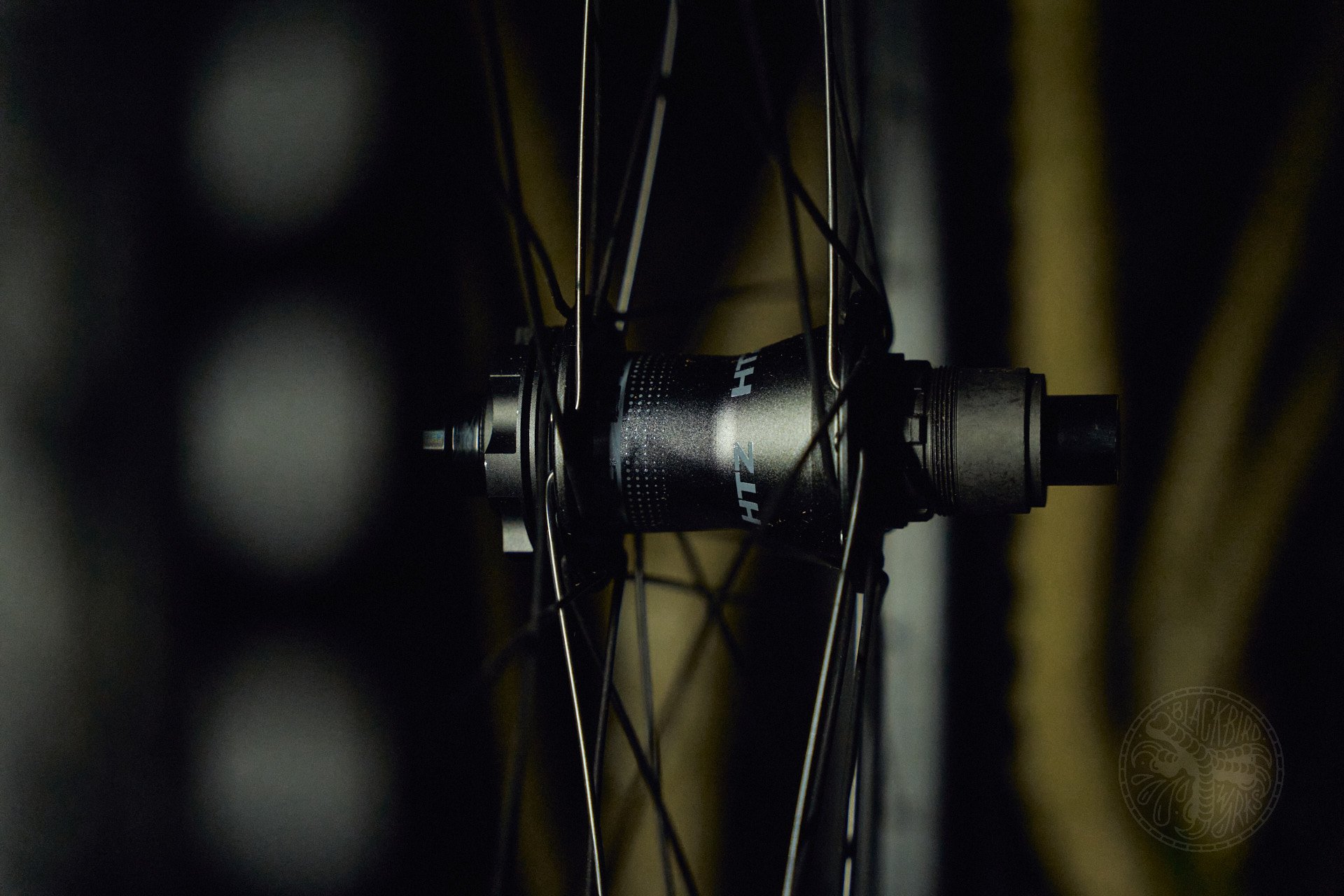

The rear with the HTZ hub. Photo WTB.

Features

- 30mm inner rim width

- 6069 aluminum alloy

- heat-treated steel freehub body

- 6-pawl ratchet system with simultaneous engagement to evenly distribute torsional forces while pedaling with a high-torque motor

- 42 points of contact for 8.5° of engagement

- heat sink behind rotor mount improves heat dissipation up to 10% on long descents

- outer diameter of the rear axle sleeve was increased from 15mm to 17mm for better durability while remaining compatible with 12mm thru-axles. The 17mm size eliminates axle flex, which improves ride quality and increases bearing longevity by reducing angular load while cornering or pedaling.

- 13-gauge butted (2.3/2.0mm) spokes are oversized at the hub

- TCS Tubeless-Ready with Solid Strip integration

- 29” and 29/27.5” mullet configurations

- XD / HG / MS driver body options

HTZ i30 - Combined weight 29" with 148 x 12 Sram XD and 110 x 15 front is 2662 grams

- FRONT WHEELS: 330 USD, 455 CAD • REAR WHEELS: 440 USD, 610 CAD • WHEELSETS: 769.90 USD, 1064 CAD

Details

Everything about this wheelset is apparently designed to withstand the extra demands associated with E-biking in the woods. The WTB copy writers put it like this: extra laps, extra miles, extra stoke. All this extra introduces more wear and tear into the already unforgiving riding equation. I put it like this: massive extra E bike weight, extra torque, extra speed and extra trail time means more chance for part failures. The rims, the spokes and the hubs are all designed to account for these extras we are told. By the looks and specs it does seem like they could improve longevity.

The hub is made to last but it is not for the feint of weight.

Hubs

The hub has a heat-treated steel freehub body. According to WTB this eliminates gouging and prevents pawl socket failure under load. The hubs use a 6-pawl ratchet system with simultaneous engagement of all pawls. This design is aimed at spreading out pedaling force. The outer diameter of the rear axle sleeve is 17mm compared to a traditional 15mm sleeve. WTB claims that this "increases performance and durability while remaining compatible with traditional 12mm thru-axles. This reduces axle flex while cornering and pedaling, which results in improved ride quality and bearing longevity."

In addition, Enduro bearings are double-stacked at the inboard end of the driver body. The goal here is to improve durability and extend bearing life. Also, there are 42 points of contact for 8.5° of engagement. Finally, the HTZ hubs have a heat sink behind the 6-bolt rotor mount. Again, WTB claims that this is to "improve heat dissipation by up to 10% on long descents, allowing you to descend with confidence despite the extra weight of an e-bike."

I asked the nerds on our NSMB chat about the sink. Gravel Gawd, Cooper Quinn, said this, "All brakes do is turn kinetic energy into thermal energy (heat). You need to put that heat somewhere and you can only transfer it to the air so fast by radiation. Conduction is much faster - hence why your calipers and shit get hot. You're generating more heat than they can dissipate by radiation. So build a heatsink." And then the other nerds, super smart, way faster riders than me, chimed in and I glazed out and moved on with the rest of the article. The heat sink debate can rage in the comments section below.

I love-hate building wheels so I appreciate this spoke cut-out shot of the 3 cross pattern. Photo WTB.

The 13-gauge butted (2.3/2.0mm) spokes on the rear hub. Photo WTB.

Spokes

The 32 spokes are laced into an asymmetric rim design. This offset is meant to allow for stiffer and stronger wheels by equalizing spoke tension between the drive and non-drive sides of the wheels. 13-gauge butted (2.3/2.0mm) spokes are oversized at the hub. WTB says this is to counteract the higher braking forces and increased motor torque of an e-bike. Each wheel is hand-built in either California or Italy.

Deniz's arty shot of the asymmetric rim design.

I like the wide flat surface.

I was so happy that the wheels came mounted with tires....then I remembered I like inserts and will have to install them; which I'll do when the rains come back some time in December.

Rims

Yes these are not carbon but in a weird way they are still sexy. The wide square profile looks great to my carbon-lusting eyes. I don't own carbon wheels though I am currently reviewing the Santa Cruz Nomad 6 that has carbon Reserve 30s. The Reserves track well, hold a line better than my current alloys in tight corners but man do they let me know how bumpy the trail is. As much as I lust for all things carbon I am starting to think I like the smoother more damped ride of the lowly alloy wheel.

WTB has made the HTZs 20% thicker than their already beefy KOM rim. The 30 mm inner rim width and 6069 aluminum alloy are aimed at increasing strength and possibly, longevity. WTB uses a nylon strip called Solid Strip that lies between the rim and tape. This strip helps to prevent tubeless tape from pushing into the spoke holes and to create a smooth interface between the tire and rim. In addition, WTB claims, "The smooth surface makes it easier to mount a tire by preventing air from escaping around the bead at each spoke hole indentation during inflation. Solid Strip also protects the airtight system from puncture in the case of a broken spoke."

What I wish I looked like on my E bike. Mark Weir railing on the HTZs. Photo WTB.

And Now What?

Well I guess now I ride them. It is easy to do back to back runs on an E bike. I can leave a set of wheels in the car, ride up and down, swap wheels then repeat and record. I'll give these HTZs a thorough thrashing this fall and winter then report back with my findings. Until then here is a pretty good promo vid with some good slow mo shots of Mark Weir hitting the rims at all angles. Finally, since I did not get a chance to get an action shot, the last photo of Mark is about how good I would have looked on these wheels (in my mind).

WTB HTZi30 wheels are 769.90 USD/1064 CAD, 330 USD/ 455 CAD front wheel & 440 USD/ 610 CAD rear wheel

Age - 57

Height - 5'9"

Weight - 175lbs

Ape Index - 0.992

Inseam - 31"

Trail I've been stoked on lately - Bukwus

Bar Width - 780mm

Preferred Reach - 465-480mm

Comments

Justin White

1 year, 6 months ago

"13-gauge butted (2.3/2.0mm) spokes are oversized at the hub. WTB says this is to counteract the higher braking forces and increased motor torque of an e-bike."

Isn't this just number-wanking? How many people are snapping spokes in the middle? Isn't the usual failure mode more likely to be pulling through the rim? These spokes are going to greatly increase the force on the spoke holes since they're not going to stretch as much as a thinner spoke. Or breaking at the nipple where all spokes are the same size? Perhaps breaking at the J-bend, but it's my understanding that can be alleviated much better with smart hub flange design versus brute-forcing it with oversize spokes.

Also, how can braking forces be higher? They're speed limited, so they're not going downhill any faster. And the e-weight isn't a real issue: I already have like 20-25 kg on most of my riding buddies and I'm not exploding wheels left and right, so it's not like the extra 10 kg of an e-bike is breaking new ground in total weight.

And I just have to repeat it, because hypocrisy pisses me off, but if there is enough extra torque going through the wheels that a super beefy wheel is required, then that same extra torque is going into the ground, which will inevitably do more damage to the trail. Plain un-boosted humans can already break tire traction and push dirt around, there is no way a bike that requires all this extra shit just to survive isn't moving a whole lot more dirt around.

I'm all for new technology used in new ways, but I just can't rectify the industry selling us both sides at once: e-bikes are just a pedal-assisted boost, just "you but faster", but you also will need massively overbuilt stuff to "handle the extra forces", and new motors with even more extended boost that make it literally not just pedal assist.

Maybe this was a bit of "thread-jacking", but I just don't like seeing marketing fluff simply repeated with zero analysis. The little extra about the heat-sink is great! I'd just like to see more like that on the other fluff.

Reply

bushtrucker

1 year, 6 months ago

I'm guessing the spoke bed of these rims is a lot thicker given their weight so having spokes pull through would be unlikely. But yeah I don't seem many modern MTB wheels break spokes so could just be overkill. Then again I don't own or work on any e-bikes so I don't really know how often their wheels fail and in what way.

Good point with the extra torque. As someone who shares their local trail network with dirtbikes I can attest to the damage a motor does moving dirt. So many ruts in winter. Not the e-bikes are there yet but in many ways I see the e-bike thing as just taking incremental steps towards most people riding fully electric motorbikes.

Reply

Ryan Walters

1 year, 6 months ago

I generally break a few high-quality spokes a year these days, and I'm pretty sure the reason is fatigue. Usually happens at the J-bend. I think the biggest reason for these spoke failures is that my rims are lasting significantly longer now. I run burly carbon rims with tire inserts and thick casing tires. Now instead of the rim being the first point of failure, the spokes usually are. Stiffer carbon rims are also going to transmit more stress to the spokes.

This doesn't so much apply to these WTB wheels specifically, just a general comment on spoke durability.

Reply

Justin White

1 year, 6 months ago

Stiff carbon rims don't necessarily transmit more force to the spokes (the total force is dictated by the impact, not the material), but they may focus the force on much fewer spokes. With a high hoop strength and minimal deflection away from round, the force is going to be concentrated on the few spokes directly opposite the the impact. Meanwhile, a rim that allows more deflection away from round spreads the force through many spokes, as more spokes not directly across from the impact point see their tension rise in order to maintain the roundness.

However, using thinner spokes that can stretch elastically can also help spread the force to more spokes, as the spokes directly across from the impact will give a little and raise tension in the surround spokes even if the rim maintains perfect roundness.

The plain old longevity of wheels could definitely be a factor, but I think that also points to smart hub flange designs being important. If the flange angles, hole shape, and hole tolerances are well designed, the forces at the bend will be spread through more of the spoke head and bend, limiting stress risers and increasing the fatigue life.

Reply

Ryan Walters

1 year, 6 months ago

I think we're saying the same thing - I should have said higher stress levels to individual spokes rather than just "more stress".

Reply

Justin White

1 year, 6 months ago

"WTB uses a nylon strip under their rim tape called Solidstrip"

This is becoming common, and it's super nice. Specialized started doing it at least 4 years ago. Some (all?) Bontrager tubeless-ready wheels use a custom-fit strip to complete the conversion. Reserve does it along with the added bead protection, and Enve copied that.

I've personally had way better outcomes with the Spesh and Bonty setups than any wheel I've ever taped myself: bead seats & seals quickly & easily, and the strips have survived quite a few tire changes, because they don't get ruined by "peeling up" and getting even just a drop of sealant under them.

Though, my pre-taped Spank wheels have been holding up well, but they've only seen like one tire change each, so we'll see if that lasts.

Reply

mrbrett

1 year, 6 months ago

I have an "ebike" rear rim on my me-bike. Seems to work OK, and I don't have stiffness or weight concerns. A higher rated rear hub might be nice though - of anything in a wheel system, I find freehubs to be the most delicate.

I see six pawls detailed for these wheels here, but is there any other info to share re: rear hub durability or longevity?

Reply

Trevor Hansen

1 year, 6 months ago

Nothing yet from these testers and nothing from WTB from their in-house testing.

Reply

papa44

1 year, 6 months ago

Im interested in the trend of E bike parts becoming beefier because an E bike can handle the extra weight, obviously because it has a motor, but surely with all these heavier parts you are going to end up needing a bigger motor? and of course once you have a bigger motor you can then easily fit heavier stronger parts, which in turn.. you know.. bigger motor..?

Reply

Pete Roggeman

1 year, 6 months ago

We saw something similar with bikes and parts in the 00s. Eventually, strength and durability went up and weight came down. Before that, we had some ludicrous, overbuilt bikes for those that were pushing them to the edge, but over time, they improved. E-bikes are going to continue to evolve pretty quickly for a while but while that happens, it stands to reason that overbuilt wheels and reinforced this and that just provides more durability.

Reply

Tremeer023

1 year, 6 months ago

I'm waiting for them to evolve into e-moto's. ;-)

Reply

Justin White

1 year, 6 months ago

What edges are being pushed on e-bikes? besides trail distance units per time unit? They don't go faster downhill than (plain) bikes, they don't go faster on flats or uphill than they and (plain) bikes can go downhill, they're not being hucked off jumps and drops any bigger than (plain) bikes already do.

And please don't mention the e-weight. The range of rider weights is so much bigger than the difference between bike and e-bike weight, it's a non-starter. If the weight thing was truly important, we would already see a whole class of parts directed at "clydesdale" riders.

Besides, brute strength is a stupid way to increase longevity. Just because a wheel can handle the instantaneous torque of an 800 pound gorilla on steroids pedaling squares doesn't mean a poorly designed hub isn't going to quickly eat into a spoke bend and make it easy to break off.

Much better to design it to smart limits (build for just a 400 pound hairless ape), allow the material properties to distribute forces (strong and thin spokes can stretch and distribute the concentrated forces coming from carbon wheels with very high hoop rigidity), and build it with very tolerances to distribute forces well (precise hub drillings to reduce stress risers at the spoke head).

Reply

papa44

1 year, 6 months ago

True, your point puts me in mind of where bmx was in the 00s, basically scaffold tubes welded together, but as they were meat powered there was still impetus to lose their weight. I feel like e-bikes will end up as emotos with crank arms slapped on, which is essentially how most people use them in London to commute or deliver food. It’s illegal for them to have a throttle or have an unrestricted engine but you wouldn’t guess from looking around. I imagine that actual mountain bikers would not have such a cavalier attitude to thrashing their bike, but I also imagine they are by far and away the minority of ebike riders so don’t get as much of a say in how they progress

Reply

cheapondirt

1 year, 6 months ago

The heatsink idea seems like a good one, but they didn't squeeze all the juice out of it yet. I want to see bigger fins, and more surface area at the rotor interface along with a matching rotor (not a new mounting standard - just lacking the usual cutouts around the bolts so as to maximize hub contact). Since it's a custom rotor anyway, and weight is a good thing here, give it lots of arms for efficient heat transfer toward the hub.

Source: Definitely Not an Engineer, or even an e-biker, just a chronic brake dragger.

Reply

Perry Schebel

1 year, 6 months ago

i'd be skeptical the fins offer any measurable benefit. something like the galfer shark rotor, sure, but pretty sure the hub doesn't see significant heat gain under braking.

Reply

cheapondirt

1 year, 6 months ago

Know what, scratch that idea, let's build fan blades onto the hub instead and get that cross breeze going.

Reply

ZigaK

1 year, 6 months ago

While we're creating air pressure, use it for air bearings.

https://www.youtube.com/watch?v=lOTWx69mghM

Reply

bushtrucker

1 year, 6 months ago

I dunno much about eMTB but love the look of these wheels/rims for touring use. Thick spoke beds are where it's at on a loaded bike. They just need to do an i40 version!

Reply

Please log in to leave a comment.