REVIEW | EDITORIAL

Wolf Tooth Waveform Pedals Are Made In House

The Daemon's In The Details

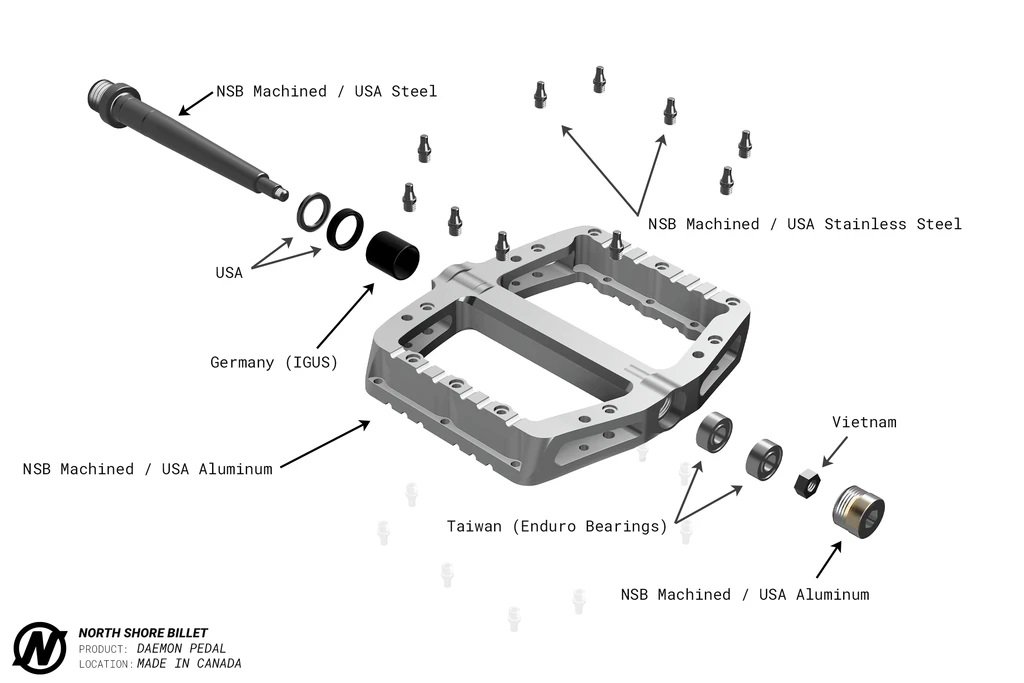

North Shore Billet (NSB) claims to have the most "made in house" flat pedal on the market. The axles, bodies, and pins of their excellent Daemon platform are all machined at their digs in Whistler, BC. I know it's a bit strange to open a review of Wolf Tooth's new platform pedals by talking about some from another company, but it's impossible to discuss these pedals without discussing their prices, and the folks at North Shore Billet have done a better job of starting that conversation with their breakdown of where the components of their pedals come from. What qualifies as 'Made In Country' varies from one place to another but here in Canuckistan, if you're in the business of manufacturing bits and bobs, your Made In Canada stamp requires that you meet three conditions:

- The last substantial transformation of the good occurred in Canada.

- At least 51% of the total direct costs of producing or manufacturing the good have been incurred in Canada.

- The 'Made in Canada' representation is accompanied by an appropriate qualifying statement, such as 'Made in Canada with domestic and imported parts'.

Your Canadian flat pedal could be mostly made here, as with the North Shore Billet Daemon. It could have a body that's machined here and then assembled with an axle and guts from a big player like HT or Wellgo. Or it could have an imported pedal body that's then post-machined, anodized, and assembled in the Great White North.

I wish that all companies selling the value of stuff they make in house would be transparent about country of origin like North Shore Billet. Image: NSBillet

I'd argue that in the former case one might as well buy an excellent HT or Wellgo pedal, one of my long time favourites is the NRG Taster's Choice, which is an unapologetically rebadged HT product. They're rebuildable and sell for a buck twenty Canadian (120 CAD). I'm not claiming that one method of pedal production makes for a better product, just noting that there's a different between something being 'expensive' and 'too expensive' based on the cost of production.

Clearly an NSB Daemon is costing considerably more to make in-house at North Shore Billet than it would cost to bring in Taster's Choice pedal parts, round the edges on them, anodize and laser etch them, and put them together despite the fact that both are 'Canadian Made' products.

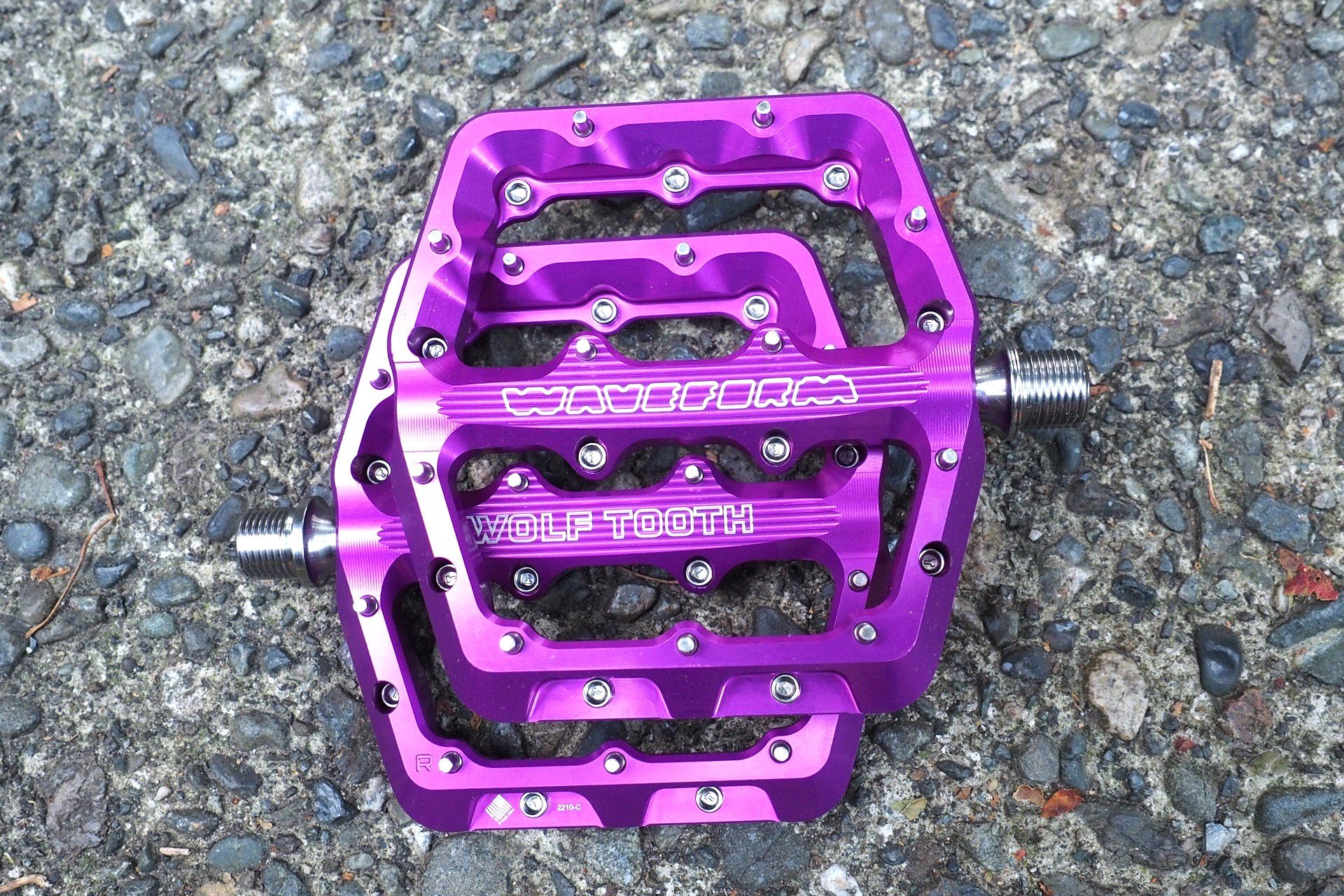

Enter the Wolf Tooth Waveform. Beautiful looking pedals with stainless steel axles that are machined and assembled in house at Wolf Tooth in Minnesota. As with the Daemon, which rings in at 210 USD | 250 CAD, the Waveform is a premium-priced flat pedal, and in the same vein that comes down to the amount and quality of in-house manufacturing.

Wolf Tooth's made-in-house Waveform flat pedals feature bodies and axles machined in Minnesota. The 'Ultraviolet Purple' is fantastic...

...but, practical as I am, I do wish they came in silver like these NSB Daemons. The ultimate finish for pedals that will be around forever.

Waveform

I admit I love the Tao of Small Companies making stuff in their own shops. That could be local to me, Made in the USA, or it could be the folks at Lazarus in Ukraine or Tune in Germany. I often can't justify the price of this stuff, but amortizing a pair of pedals I really like over the long term makes sense as long as they're straightforward to rebuild and fully supported. One of the neatest features of the Waveform pedals is the availability of the separate components. That includes left or right pedal bodies in any of the colours they sell. The whole breakdown is in their pedal service area.

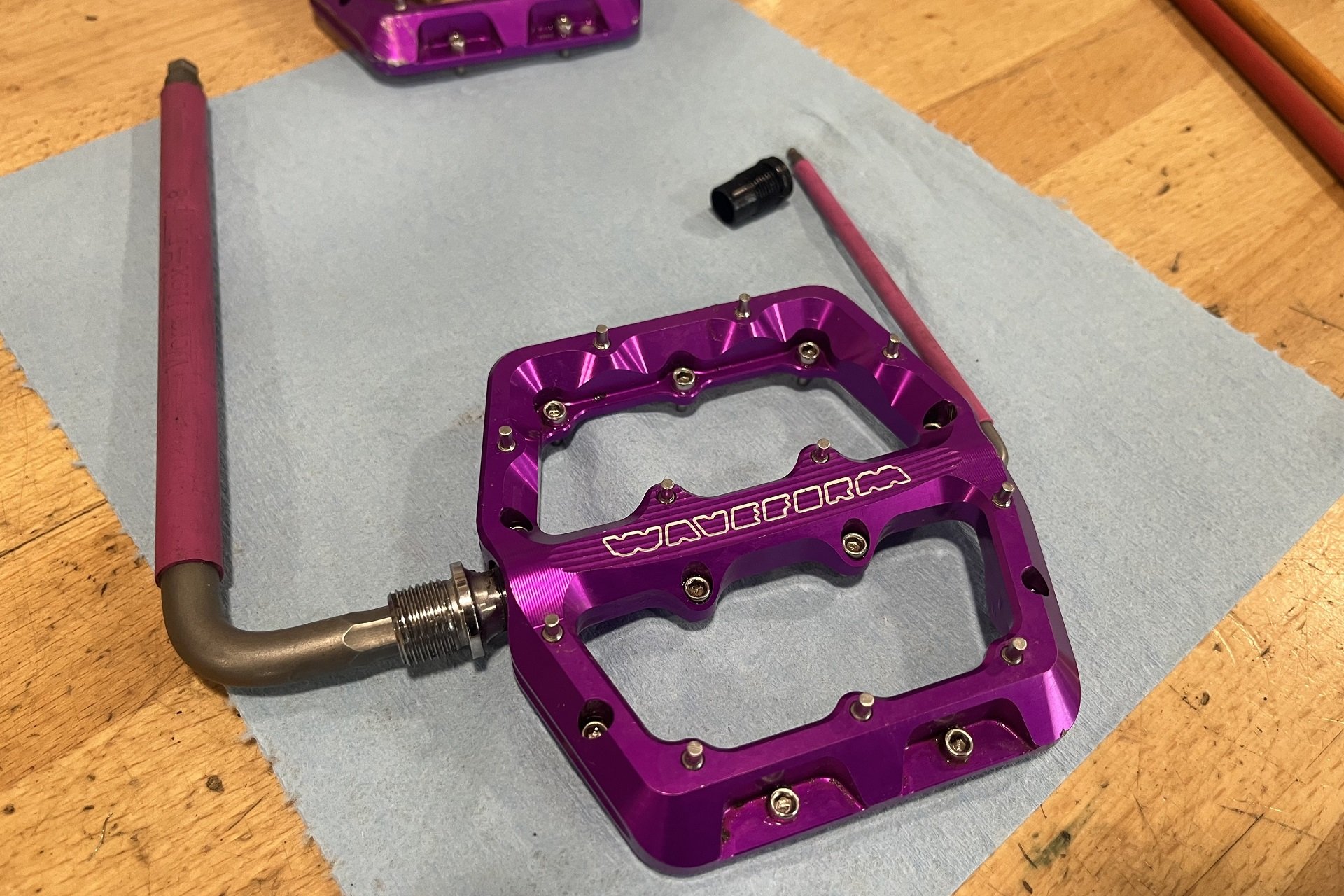

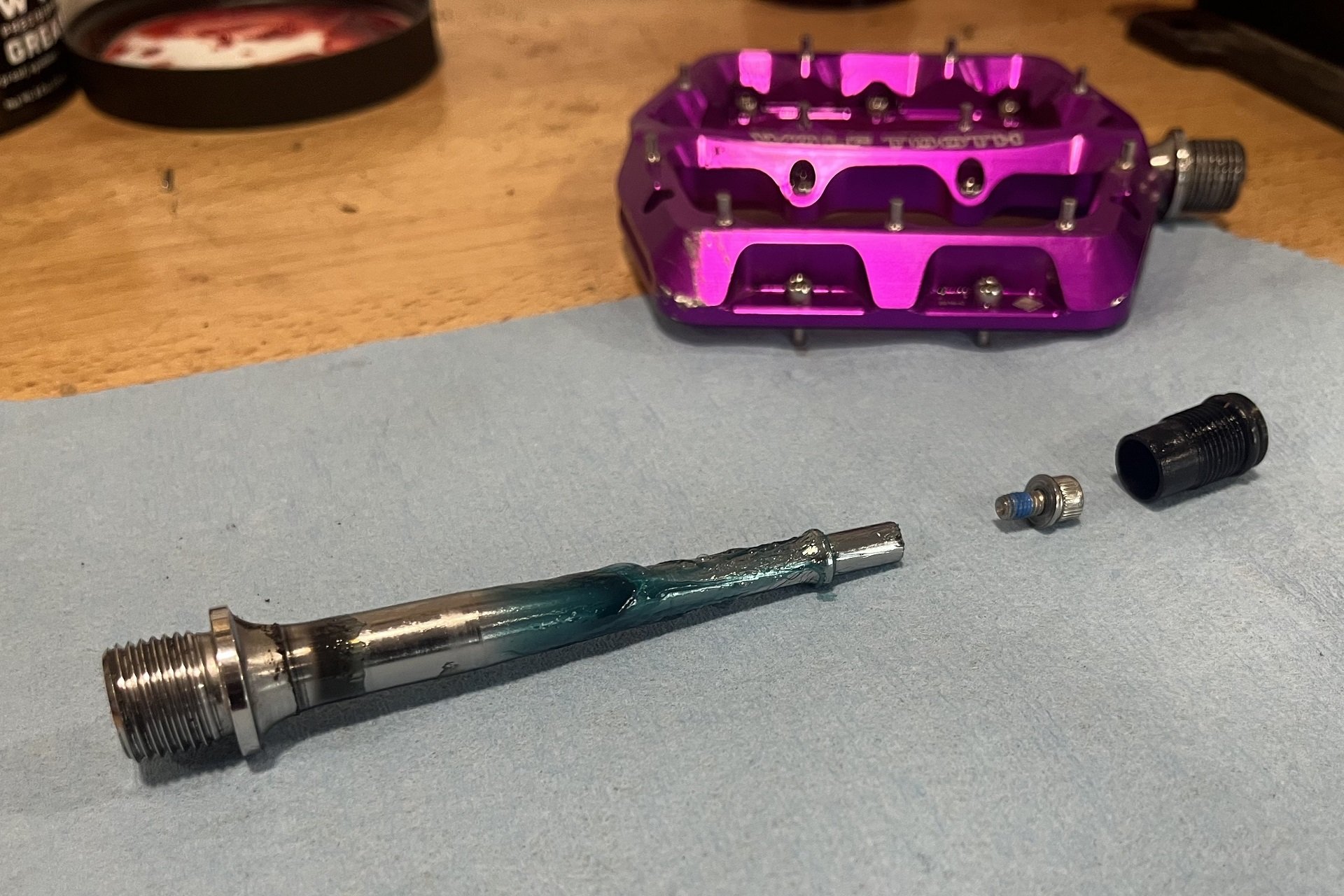

On the service note, my other favourite feature is that the Waveform flats use a 3mm hex head screw instead of an 8mm nut to hold the axle in place. I would love to see every pedal from budget to bourgeois ditch the axle nuts in favour of a hex or Torx head bolt. I have tools coming out of my ears, including a couple of long thin-wall 8mm sockets, but it's more convenient to not have to dig out a socket set whether I'm doing a quick re-grease or a full rebuild and the only negative is a slightly more complex manufacturing operation. I know plenty of folks living in tight spaces who have a multi-tool and an 8mm hex for installing pedals and that's all they'd need to open the Waveform.

All small parts, including axles and pedal bodies, are available separately.

It's a 6mm hex key to remove the end cap and then an 8mm hex and 3mm hex to remove the stainless steel axle.

I wish every similarly laid out flat pedal would ditch their 8mm nut in favour of a hex or Torx head bolt.

Wolf Tooth makes two sizes of the pedal body:the large measures 112mm x 106mm and the small is 105mm x 99mm. In both cases, the shape of the pedal is meant to maximize contact with your shoe and minimize contact with the trail. Both versions have eleven pins per side. The most unique feature here is that Wolf Tooth has a printable template so you can compare how your own shoe will interface with both the large and small sizes.

In addition to being easy to service, the Waveform is a very easy pedal to ride. The stainless steel T-Pins and Wolf Tooth's layout and shape combine for reliable traction and it's the best combination I've used to date with my Crankbrothers Stamp shoes. The bite is consistent, while still allowing for my preference of being able to move my feet around some. With my Leatt DBX 2 and Giro Latch shoes, I find the stainless steel T-pins to be on par with the custom stainless steel pins on the Daemon and I suspect that would be the general feedback from most riders trying both options.

As good as they are, performance alone would not get me to drop the money for the difference between the Waveform or Daemon and my new budget favourite, the 110mm x 120mm Oso (65 CAD) but I can get enthusiastic about the concept of forever pedals, in combination with my not so secret lust for nice things, to amortize the difference.

Tapered edges, stainless steel pins, and the inboard bushing is well sealed.

I was surprised they didn't use their own WT-G grease inside as I've had excellent experiences with it in pedals on the wet coast

I now have one pedal that's stock and one with WT-G for a long-term comparison.

It's hard to say if the tapered edges and pedal shape of the Waveform do prevent unwanted trail contact. I can say the stunning anodized purple finish is surprisingly intact given the number of rides I've been on, but my only disappointment with the Waveforms is they're not available in silver. Like the Daemons, these pedals are a significant investment that I'd expect to have for many years, and from a meter away it's amazing how sweet a fully throttled pair of polished silver pedals still look.

Wolf Tooth's pedals are being concave with the outer edges measuring 14mm and the center being 12.5mm in height. This is 1.5mm of pedal body concavity and with my Stamp shoes, I find it nicely unnoticeable compared to pedals I have that are perfectly flat. Remarkably the Daemon only has an additional 0.5mm of body concavity but feels more shaped. I've ridden the Waveform exclusively with a more mid-foot position and traction and landmarking are both excellent, which should be a given at this price, along with the stunning finish. What is remarkable about the Waveform is the consistency of landmarking. For those whose dislike of flat pedals comes down to an inconsistent foot position, I've yet to use a pair of pedals where my feet so naturally ended up in the same position every time. It's not something I can easily explain and maybe it's not consistent between riders, but it's noteworthy for me.

Superior grip with eleven stainless steel pins per side. For my shoe size, the center-rear inboard pin is not always in contact.

I've used them with three different pairs of shoes but the Crankbrothers Stamp is my preferred combination. (Photo: Penny)

Whether climbing and descending, I'm always looking for maximum traction and being able to move my feet around.

I would love to see every high-end pedal brand selling every small part of their pedals separately. I think there's a business case for it. Let's face it, no one is paying shipping on a set of T-Pins or some pedal seals, but as an order builder with a chainring, some grips, and a bottle of lube there's a case to be made. Also on the replacement parts note, the stainless pins will fit other pedals using rear-entry T-Pins as well if you're sick of sh*tty looking rusty pins you could swap them out for Wolf Tooth's for 20 USD | 28 CAD for a 50 pack.

In the meantime, the Waveform is an excellent flat pedal option for those looking for maximum grip in a neutral shape and willing to commit the extra treasure for a made in Minnesota product. The pedals have a five-year warranty against defects in manufacturing or materials. They are currently sold in Purple, Orange, Black, and Blue and I'd expect to see other colours in the future - including, I hope, silver. They sell for 200 USD | 280 CAD and there's significantly more information at Wolf Tooth Components.

Comments

DBone57

1 year, 4 months ago

I thought about these to replace my Tenet Occults, but I went with Tenet Omens for two reasons. First, the wider Q-factor of the Tenets as I don't like pedals that hang close to the crank arm, and second is silver.

Reply

Andrew Major

1 year, 4 months ago

I could see both Wolf Tooth and NSB selling pedals with longer axles (and axles separately) in the future. That flexibility is where small batch in-house manufacturing shines. I’m both happy where my seat fit on both pedals and also wider stance-curious after other experiments.

As beautiful as this purple is - and my photos don’t do it justice - I do think looking at my Daemons makes a great case that the highest value choice is silver if cosmetic appearance is being factored into the purchasing decision.

The Tenet pedals look good, what pin setup did you go with?

Reply

DBone57

1 year, 4 months ago

I prefer the full length sharp pins rather than the rounder grub style pins. It's cool that Tenet includes both styles, plus washers if you want to lower the sharp ones. Even though it didn't go in their favor, I really appreciated WT's printable template as it made my buying choice easy.

Reply

Andrew Major

1 year, 4 months ago

As with the NSB sourcing breakdown I think the sizing template is a nice add-on that every premium pedal brand should consider.

Reply

Kos

1 year, 4 months ago

Gotta love Wolftooth's backyard, made-in-house, success story, not to mention the quality of their products.

Highest marks!

Reply

Andrew Major

1 year, 4 months ago

I’m a fan of any brand making unique high quality stuff themselves - it tends to be smaller outfits but for example Industry Nine is fairly huge now and We Are One is running multiple shifts.

Reply

Kos

1 year, 4 months ago

Minnesota ex-pat here, so I've got a soft spot for their success stories. Park, Wolftooth, Onyx, Greg Lemond....

Reply

kcy4130

1 year, 4 months ago

There's a good reason most pedals use a nut (and externally threaded axle) instead of a shcs aside from machining ease. A solid shaft is stronger than a shaft with a drill/tapped hole in it. Wolftooth products generally seem to be well engineered, and I'd assume these pedals are too. Might be thinner cartridge bearings (i.e. larger id for same od) to keep shaft larger. But without looking at dimensions that's just speculation on my part. Would explain why they use three bearing instead of the more common two.

Reply

Andrew Major

1 year, 4 months ago

I specifically asked Wolf Tooth about disadvantages of using a bolt instead of a nut and there is no strength concern. To back that up, I’ve seen a fair few broken pedals but never one that’s broken at that end.

Interesting comment about the bearing size. They look to be about ~ the same size as usual but that was a failure on my part not measuring them. I’ll fix that this week and post up comparable dimensions. That would make sense if they’re slightly larger ID and so they used three.

More work to machine but like using an HG tool for fork top caps or putting out a 30mm BB that uses the same tool as the original Zipp setup, I love anything where companies simplify the quantity of tools we need to own.

Reply

kcy4130

1 year, 4 months ago

They could be the same size. Which might be fine: I'd have to reverse engineer it to know, but that'd be a whole lot like the work I'm being paid to do and should be doing, hehe. But again, Wolftooth seem to have their poop in a group engineering wise, so I'd be surprised if it wasn't fine. And yeah, a hex is way more convenient than looking for that one long thin wall socket that you had to buy specially!

Reply

Justin White

1 year, 4 months ago

How are those sizes listed? Length by width? Width, including axle, by length?

Is length the overall length or just the length of the "top" where your shoe actually touches? If the latter, would it be appropriate to include the forward offset due to the leading edge chamfer?

If it's length by width, especially if length is just the top surface, those sure seem like pedals I could love to death. Although the large pockets carved out for the front pins removes most of the leading edge chamfer, leaving a nice square edge and the heads of those pins right in the strike zone, so I have to wonder if they might be a bit more grabby that some other pedals with a more complete chamfer and more tucked in pin heads.

Reply

Andrew Major

1 year, 4 months ago

A good chance again to highlight the printable template. I think this is a neat feature.

I’d also meant to make my own version of this photo:

The dimension is length X width of pedal body but let me measure it myself this morning in terms of a where-to-where so it’s easy to make real life comparisons.

Reply

Andrew Major

1 year, 4 months ago

Measuring the widest points of the body (center-long and center-wide) where my shoe’s actually contacting the pedals almost square and then of course it tapers towards either end.

Reply

Justin White

1 year, 4 months ago

Perfect! Are those the smalls? Looks like the 105mm length refers to overall length and not contact area. Which I think is totally normal, but also quite unfortunate since leading edge chamfers are quite varied which means that pedals with identical "length" might have different contact surface sizes.

This one still looks and sounds good enough to make it to my short list: RF Atlas, Spank Spike/Oozy, Spesh Boomslang, WT Waveform (in no order, though maybe by price to be realistic).

Reply

Andrew Major

1 year, 4 months ago

The new Atlas looks good, I’d like to try them.

These are the larger of the two Waveform options.

I’d love to see at least every premium pedal brand offering printable templates. Doesn’t help with shape (convex, concave, flat) but it at least provides a good idea of where my shoe would sit relative to the pins and I could trace other pedals over them for a better visual comparison.

Reply

Justin White

1 year, 4 months ago

Those are the large?! Wow, there must be some parallax in effect, because I don't see where they got 112mm or 106mm from anywhere! Still looks like good a good size platform, though.

Reply

Andrew Major

1 year, 4 months ago

I always ride the larger platform when there are two options. This is certainly no Dagga but it feels on par with other pedals I'm using. That's why I didn't think to check the measurements (thanks).

I can see 112mm by 106mm in terms of the absolute platform end to end (if you traced it and measured on paper) but the actual standing surface area is certainly smaller. As you note - one of the challenges in comparing one pedal with another.

cheapondirt

1 year, 4 months ago

Those Osos though! Will there be a review?

Reply

Andrew Major

1 year, 4 months ago

Absolutely. I’ve enough hours on them now to talk about r everything but the long term durability - the ask me a year from now follow-up - so I just need to pull them apart to photograph the guts.

Reply

Shackleton

1 year, 4 months ago

Would very much like to see this review. Without giving too much away, can you comment on the actual platform size that you stand on and pedal thickness?

Reply

Andrew Major

1 year, 4 months ago

They look thick (18mm) but there’s none of the axle/bearing bulge that some folks really dislike from other resin pedals. Like the Waveform they’re listed as being concave but the actual concavity is such that they feel very neutral underfoot. I’m riding them very mid foot. Grip is good, not on the level of these Wolf Tooth flats or my Daemons but totally usable and I don’t use the stickiest shoes generally (will visit this in my piece).

The platform is on the larger size of one size fits most (almost like it was planned to be the larger of two options, but not so large that I can be certain that’s the case). More on that too.

Thickness is a key discussion. Even with my bike being very low and having ridden much thinner pedals like the WahWah 2 it’s not something I notice at all on the trail.

Hope that’s helpful!

Reply

Shackleton

1 year, 4 months ago

Grand, thank you. I look forward to the full review!

Reply

Flatted-again

1 year, 4 months ago

Is there a list somewhere of Small Companies Doing Cool Stuff (SCDCS)? I'd never heard of Tune and Lazarus, but others like Intend or Beast pop up every once in a while.

Reply

Andrew Major

1 year, 4 months ago

Doombars, Oddity, Endless Bike Co (Kick Ass Cogs), Paul Comp, and on and on. I’ve never seen anyone try to put any sort of definitive list.

Tune always comes to mind as they’ve been doing their thing forever which is making insanely lightweight bike components. I’ve never owned or tested anything of theirs.

…

I came across Lazarus as one of a collection of Ukrainian manufacturers who were raising money to defend their country when another neat manufacturer I’ve followed for years, Raketa (from Russia) boosted them in solidarity.

Sorry in advance if this is me being too preachy or not adequately respecting a wall of mountain-bike-websites-as-entertainment-only but what the Russian government is doing to Ukraine, never mind their own citizenry, is awful and there’s all but nothing that individuals elsewhere can do about it other than show support. So I picked up a couple stem caps and link to Lazarus in case anyone else feels inclined to go down that rabbit hole and do the same. And yeah, I know, it’s just a stem cap.

Reply

Cee Cee

1 year, 4 months ago

At least Clive de Sousa admitted that he rides SRAM Red.

Vietnam, you complete me

Reply

Justin White

1 year, 4 months ago

"On the service note, my other favourite feature is that the Waveform flats use a 3mm hex head screw instead of an 8mm nut to hold the axle in place."

Wasn't that the biggest flaw in the first-gen RF Atlas pedals? The bolt (I think it's a 3mm) holding the axle in was allegedly prone to breaking off? I mean, mine are 3 years old and I'm starting the crack the pedal body itself* while my axle bolt has been fine, but there are stories of that bolt failing and pedals failing off at very inopportune times.

*(outboard of the axle bolt, where the body is thinnest to allow the bearing press to slide in, but still...)

Reply

Andrew Major

1 year, 4 months ago

Different architecture in that the bolt on the Wolf Tooth pedals is still captured by a long axle end cap, the same as most pedals using as nut.

The previous generation Atlas pedals where I’ve seen issues - always with the pedal coming loose first - are always missing their outer cap.

Reply

Andrew Major

1 year, 4 months ago

That is to say that every Atlas pedal I’ve seen issues with has been missing the part that’s green in this photo and either is loose or was loose.

Reply

Justin White

1 year, 4 months ago

Nah, pretty similar architecture. The green thing (and they come in black, so they might look "missing" sometimes even if they're not) is the axle end cap, and definitely captures the axle fixing bolt. On both designs, it's only protective, and only touches the pedal body on both designs, thus does nothing to hold the pedal on. Indeed, it should keep the bolt from completely unscrewing off the axle , so yes, the pedal would get very loose before it fell off, but I've heard more horror stories of the Atlas's 3mm bolt breaking than of it disappearing.

So yeah, maybe the external end cap on the OG Atlas is prone to get bashed off*, but even an internal end-cap that does stay put isn't going to add any strength to the axle fixing bolt.

*(one of my pedals has messed up threads there from the endcap getting hit, so I just crank that endcap back in and it's been there for years. Cross-threading > loc-tite?)

Reply

Andrew Major

1 year, 4 months ago

Yeah, I’ve rebuild lots of these pedals. Just pointing out that in terms of issues that all the ones I’ve seen are missing parts - i.e. the pedals are being run loose and the rider clearly isn’t noticing it / the missing components.

Anyway, as with other stuff I will revisit the Waveform flats in the future but given the architecture is standard and the end cap butts against the bearings, providing support, I don’t anticipate any issues.

Reply

Justin White

1 year, 4 months ago

Pretty sure the end cap doesn't butt against the hex screw. The hex is fixed to the axle, the end cap is fixed to the body. If they touched, there would be friction. It does look like WT is using the end cap to help hold the outboard bearings snug in the body, by pressing against the outer races (hence the two lengths of end caps to match the 2 body widths), but it's not going to be touching the axle-fixing bolt.

I do wonder if WT's use of left-hand threads on the right-side fixing bolt is going to greatly eliminate loosening of that fixing bolt... That might be the most important difference to the OG Atlas, because there is certainly a chance that most/all of those broken Atlas bolts only broke because they were already loose.

Reply

Andrew Major

1 year, 4 months ago

Yes, apologies, I meant the end cap is preloading the system (against the bearing). Fixed & thanks.

Justin White

1 year, 4 months ago

Hmm, unless we have a different definition of "preload"... The endcap is only pushing against the outer races, which should already be static/fixed relative to the pedal body. Any bearing "preload" (as I know it) would come from the axle to fixing-bolt interface: ie: if the axle is shorter than the bearing stack (plus body), the fixing-bolt will be loading the bearings before it bottoms on the axle.

Andrew Major

1 year, 4 months ago

I’m using ‘preload’ in this case to say that the pedal body moves on the axle unless the end cap is tightened. With it being tightened there shouldn’t be much stress on the bolt. Stress on that fixing point (nut, bolt, axle end, etc) is going to come from pedals not being tight. The same as with the previous generation Atlas. Apologies again for the lack of clarity.

Larrabee

1 year, 4 months ago

Pedal pin toughness: the buttressed tall=5.5 mm) stainless steel pins on my Squidworx pedals are all fine after a year’s riding.

I no longer “maintain” the trails by shaving down rocks and shredding logs and stumps with my pedals — as I did in my greenhorn year of riding. I roached a pr. of Stamp 1 pedals every 6 months back then.

I do contact the odd hunk of bedrock with my Squidworx (I weigh sub-105 kg only in my dreams), and the pins are TOUGH. Never bend, never break. Don’t underestimate a buttressed design.

Reply

Please log in to leave a comment.