Aluminum v. Carbon

Duelling Knolly Wardens - Carbon vs. Aluminum - Final Verdicts

This is not a Shoot Out

Brand A vs. brand C with similar travel, wheel size and price;.this is pretty common stuff. Testing bikes that are virtually identical aside from the frame material is less so. And I assumed it would be easier; because carbon is better! Noticeably better! It has to be FFS because the industry has been extolling its superiority since carbon frames first appeared. And the industry never, ever lies, misleads or conceals...

In fact the answer was more complicated for the three of us, and the bikes were close enough that our opinions sometimes conflicted. We were careful not to talk about our impressions before submitting our 'results' so that our opinions wouldn't be diluted. In that sense our process was pure, in other ways it was a little muddy.

Here are our Impressions...

The bikes. For more on the spec and other details check out our first impressions piece here.

In case it isn't obvious, this is the carbon version.

Cam McRae's Findings

Since the raw material has a higher strength to weight ratio, better sound and vibration damping characteristics and because it can be molded into any shape an engineer or M.C. Escher can imagine, the finished product will be significantly and noticeably better by most measures. It should be stiffer, both in terms of transferring energy from your meat engine to forward motion and in terms of precision handling. A comfort tax often accompanies an increase in rigidity but because of the structure of a laid up carbon frame and the material itself, that tax should be waived. This is what conventional wisdom tells us, along with every marketing blurb ever.

And carbon frames look amazing. My first mountain bike was a smoothly fillet brazed Ritchey, and even the pearliest tig welds have always felt a little unfinished in comparison. Carbon frames take the organic form to loftier heights and for me the most beautiful frames (not necessarily the sweetest or most desirable) are made of carbon. There are frames where straight lines seem to have been banished with the exception of the underside of the bottom bracket shell. Others preserve angularity but frame junctions, which aren’t really junctions at all, disappear as syrupy curves merge.

Both bikes held an edge well and tracked accurately.

Recently aluminum seems to be bridging beauty gap* as hydro-forming techniques improve and expand allowing both more complex forms and wall thickness variation (both inside and out) and CNC machining continues to be refined. Many manufacturers attempt to build aluminum frames that mimic the form and impression of their carbon siblings, both with the aforementioned techniques and with improved painting and finishing. The Trek Farley we have been testing is aluminum throughout but from a distance it’s hard to tell.

* These manufacturing advances should also close the performance gap but carbon seems to be advancing at least as quickly in this regard.

While I’m a sucker for looks, I’d saddle up a lipsticked warthog if I felt it could help me ride better and faster and squeeze more juice from each ride. But since carbon should win out I should get both damnit. With a hefty wallet penalty of course.

Lots of our testing took place in inclement weather.

The Process

Since I’m not a racer and no longer have aspirations in that regard, the unscientific approach seemed to be the way forward. I’m unconvinced about back to back timed runs anyway since there are too many variables that can’t be controlled for. Were you warmed up better for the second run or more tired for the second run? Did the second run allow you to read the trail a little better? Those factors and my lack of consistency, likely the result of a corresponding absence of skill and discipline, made clocking the difference impractical.

So anecdotal impressions were the way forward. I spent solo days on both bikes, sometimes on consecutive days and other times with gaps and we did back to back runs as well, ensuring tire pressure and other settings were as identical as the parts spec. All of my rides on the Wardens were on the North Shore, exploring the techgnar.

Go ahead and point them down - even through the bony bits.

Stiffy-ness

Some of my impressions defy the aforementioned conventional wisdom and overall, the differences I perceived were much less noticeable than expected. In terms of handling, it seemed to me the aluminum frame was more precise. I had more confidence it was going exactly where I pointed it, whether for better or worse. The rigidity perception swapped when I put some power down; the carbon frame gave the impression every kilojoule expended (micro joule?) was reaching the rear wheel. The aluminum seemed to have slightly more flex at the bottom bracket during out the saddle efforts, again for better or worse.

Posers.

Noise

I paid particularly close attention to this one because it seemed unlikely the bikes would be close. Both frames rode quietly and I’ll be damned if I could tell the difference. Likely stones bouncing off the downtube would have exposed a distinction but I can’t recall that happening on either bike (or I didn't hear it) so it remains a guess.

Vibration

This was another area where I failed to perceive any gap. Neither Warden rattled my bones more than the other and both dissipated hi frequency forces effectively. It's possible that higher speed trails (the old shale section on A Line?) and more riding in the dry would have exposed a difference.

What does braaap sound like under water?

Overall impression/Performance

I found the Wardens delivered a remarkably forgiving and neutral ride. The progressivity of the travel allowed for a nicely bottomless suspension feel with good support throughout. I found myself diving into some challenging lines on my first ride (on carbon) and even rode a tricky move I hadn't had the nerve to attempt earlier. The ample travel and slack head angle savoured rowdy lines. I found the bike to be relatively nimble in terms of getting off the ground but less so in terms of reacting quickly and swapping lines. I wouldn’t call it a slow handling bike but there are others in this category which I would say react more quickly (the Transition Patrol and Yeti SB6 being two examples). The bikes were however quite willing to get on the rear wheel, a trait I always appreciate (despite my inability to consistently hold a manual).

Cornering bite was very good and my confidence in the Warden’s ability to hold an arc in bumpy circumstances grew with every ride, likely the result of an extremely stout rear end and the quality of the rear travel, but the Fox 36 and the Minions (2.5 front and 2.4 rear) deserve some of the credit.

Some others didn’t appreciate the way the bikes climbed but I found them effective on both fire roads and in technical situations, with excellent traction and pedal bob that was predictable and measured with damping engaged. On tech sections I would actually say the bike is a stand out climber. The riding position (not excessively long by current standards) suited me as well, being someone who is longer of leg than torso.

Glaringly I didn’t discern between the two bikes in my descriptions above. That’s the result of my inability to notice a difference between them in any of these areas (aside from bb flex mentioned previously). In fact, I feel a little duped

Cam's riding specs: 6'0" (183cm) 165lbs (75kg), likes to ride steep trails with lots of interesting features. No longer hucks to flat unless it's unavoidable.

THE Answer

Have we been sold a bill of goods by the bike industry? Companies have been telling us CARBON IS BETTER! since it first appeared in our sphere and that is likely true in many cases by some measures. The Warden however is somewhat unique in a few aspects. Noel Buckley told us that his answer to the environmental challenges* of manufacturing and disposing of carbon frames was to make something that he feels will be incredibly durable and long lasting. If it stays out of a landfill for a long time there is a pretty clear environmental benefit, and an even more tangible benefit for riders. This approach means the carbon bike weighs only slightly less than the aluminum with identical parts (on my scale that is - Cooper's results differed). This should mean the laid up frame is stronger by almost every measure and it could also explain areas where I expected to notice a difference but didn’t (sound and vibration damping perhaps?).

*In theoretical terms aluminum is 100% recyclable without any loss of natural properties. Carbon cannot be re-used with currently available technology

Another difference is, unlike many bikes the Warden competes with, it was designed as an aluminum bike first. Noel downplays the significance of this (accurately) but the fact remains that there are structures you can create with carbon that are either very difficult or impossible to reproduce with drawn aluminum tubes. So I can’t say the conclusions I have come to about the distinction between carbon and aluminum Knolly Wardens can be extrapolated to other bikes.

Back to the issue at hand. Given how close the performance and ride characteristics of the two frames seemed, and considering I perceived the aluminum bike to be better than the carbon version in one area, I’d be hard pressed to recommend opting for the more expensive carbon frame, unless your priorities are energy transfer and sex appeal. I’m unable to draw conclusions regarding longevity, durability and performance life, which could each be better with the organic frame, but that is speculation based on conventional wisdom regarding carbon and the overbuilt nature of this carbon frame in particular. The takeaway is this; I wouldn’t hesitate to purchase the aluminum version of the Warden or to recommend it, but if an extra G-Spot in your wallet is more important to you than the intangible benefits of a carbon frame and sprinting performance, Al is your guy.

Pete Roggeman's thoughts

Depending on how you look at it, this experiment was immune from failure, or doomed from the start. Immune because we deliberately kept it subjective, and aren't making claims about our observations being anything other than that. Or doomed because if you choose to be skeptical, you could accuse us of copping out by not using timed runs and dutifully recording observations after every run or ride. No matter where on the spectrum we fall in this carbon vs. aluminum process, most of our conclusions are not going to apply to the same process with another brand's bikes of both materials.

My first few rides were on the alloy Warden, and it took a while to get used to a few things. While it is an able pedaler, I didn't find it to be particularly efficient when compared to the best climbers in the category - at least on smoother climbs. In the technical stuff, I appreciated the ample rear wheel traction, and not overly long wheelbase. It was where you could more easily gauge the Warden's climbing efficiency - when you aren't standing and yanking on the bars, but instead sitting and spinning - that I found myself a bit disappointed. Here I blame the slack seat tube angle; while the effective STA is listed at 74 or 75, the true STA is a saggy 68, and that put me in a non-optimal position when the saddle was all the way up.

The other thing I found myself having to adjust to was the nimble handling. I found the Warden handled better when I rode it like a trail bike rather than a beast. If I took an active role in keeping it in line, with both hands 'on the reins', I found the results were better than just pointing and smashing. This is not bad. In fact, for most trails, it might be preferable, and on the Shore - arguably the terrain the Warden was most closely designed for - it's right at home. Where I didn't like it as much was on steep lines at moderate speeds - in those cases the Warden felt a bit short and twitchy. Once I got used to the faster handling, I was able to take advantage of the excellent traction which made up for some of its fast twitch manners, but going to this bike from the Santa Cruz Nomad Mk4 was very telling - they're very different bikes in that situation.

The perfect climate... for moss, ferns, and salal.

Carbon vs Alumin(i)um

After a few rides to get used to the alloy Warden, we did a day of back to back testing. Two laps on the alloy bike were followed by jumping onto the carbon one. The first reaction, which was immediate, was that the carbon bike felt damped to me, but the difference was visceral in a way I hadn't imagined - I was not only feeling a difference in my feet, hands, and arms - I was feeling it with my ears. The carbon bike was cutting vibration in a way I'd never felt so clearly, and I was hearing the difference as much as feeling it with my other senses. It was a bit like driving at highway speeds and having the road surface underneath you change, and noticing the buzz of the tires on a rougher surface only when it stopped. Going back to alloy confirmed it, but that wasn't unpleasant - just different. In terms of riding characteristics that more closely impact performance, the alloy bike felt stiffer to me, but I chalked that up to the slightly more direct transmission of trail chatter, rather than actually concluding the alloy bike was stiffer. Both bikes felt great in the corners - stiff enough to hold any line, but short enough in the back to allow a wiggle and a snap. Going from side to side or linking turns, the carbon Warden did feel smoother, more refined. Again, though, the alloy bike didn't feel harsh or not refined, but I did sense a pleasant combination of stiffness as well as comfort on the carbon Warden.

The two Wardens at Beere Brewing.

Pedaling the carbon bike did feel more efficient at the pedals, but I can't confirm it was actually faster. The alloy bike's back end certainly felt more rigid in the vertical plane, but once again, that was not unpleasant - just noticeable. To be truly honest, if I took off my review hat and got lost in the moment of the ride, the carbon vs alloy difference was often moot: there is no doubt the Warden, in any form, is a blast to rip on. Give me either one and you could call me happy on any trail where a capable trail bike is the right choice. Once into the really steep or gnarly, I personally prefer just a bit more wheelbase for stability, but I did get used to the Warden's feel and after 5-6 rides it felt great everywhere.

Climbing impressions were a little mixed.

Conclusions

Knolly's alloy bikes are not low-cost options of their plastic versions - each tube is custom drawn and butted to their specification, and Knolly worked on perfecting alloy bikes for years before finally moving to carbon. Nor is the alloy Warden harsh to ride - in truth it has quite a refined feel. In fact, having ridden carbon bikes about 85% of the time over the last several years, I'd have to say the alloy Warden felt less different than I expected it would, and I came away impressed. What we have here is not a matter of good vs better, but one sensation vs another. Across the two platforms, the difference in frame material will cost you $1,500, and that is a lot of money for spare parts, beer, and gas. If the money matters - and for almost all of us, it does - my recommendation would be to choose alloy and not look back. You won't be getting an unsophisticated metal bike - quite the opposite - it is carefully designed and built to be a high-end alloy frame. The carbon, then, could be reserved for those who think that 0.9 lbs is a worthwhile difference (not to me) or who can discern an efficiency difference between the two - or a ride quality difference that they prefer. In this case, at least, my conclusion is that carbon is not better - it is different, and will still be preferred by some riders, but the choice is not overwhelmingly clear-cut when the price difference is north of $1,000 CAD (in this case, far north).

Yes, there are plenty of reasons to choose a carbon bike over an alloy one and yes, marketing would have us believe that riding a carbon bike makes us faster, lighter, or sexier. Coming out of this little experiment, I was happy to have not preferred the carbon Warden by a large amount, but I did notice some differences between the two. In the end, for my money, alloy is the choice, but the carbon Warden is a wonderful bike if you have the money, or if one of the advantages of the carbon tax resonates with you. At the end of the day, for me riding is about fun and while performance is part of fun (speed, capability, weight), the good news is that both of these bikes were equally fun. So, the fun:value ratio winner goes to the alloy bike for me.

Perry Schebel rode along for the photos but wasn't recruited to pen his thoughts about the bikes.

Another muddy shoot.

Cooper Quinn (médecine man) was enlisted to give his take on Warden vs. Warden.

Cooper Quinn's Assessment

To explore the Fundamental Question, step one with the Wardens (Wardenii? Wardii?) was to break out the calipers and gauges to get setup as equal as possible; tire pressures, cockpit, and then plugg in the recommended damper settings from Knolly. For a few rides any adjustments made to one bike were made to the other. This wasn’t a test of the Warden as a platform, suspension, geometry, etc; but what was the effect of the different frame materials, and did any of it matter?

It is worth mentioning neither Warden pedals spectacularly. Knolly isn’t hiding this, and points out you should use the damper platform to improve pedaling performance on the ascent. Why make downhill sacrifices when dampers are so good now? With modern dampers I think that can be a fine sacrifice, and the Wardens are happy enough if you flip the switch, sit your butt down, and spin away. This reflects a fair quantity of the riding here on the Shore, near where Knolly is based.

About Cooper: I'm a 5'10" 165lb reformed downhiller who moved to BC when 42lb bikes were light, and wheels came in one size. I'm no longer afraid to pedal long distances for long periods of time, but its means to an end; a sweet descent, or killer view. To put it another way, I'm pretty stoked on all these slack, aggressive, 100-170mm bikes that weigh nothing and are as comfortable smashing steeps as they are pedaling all day - they're right up my alley

The Fundamental Question:

If you could ride two identical bikes whose only difference was frame material, what differences would you notice, and would ride quality help you decide whether the 'carbon tax' is worth it?

Cooper leading Perry.

But are they really different?

Yes. Shuttle laps on day 1, I flipped a coin, and ended up on the carbon frame second. Differences were immediately apparent - all other things being ostensibly equal the carbon bike feels significantly stiffer - but not as you might think. Neither bike is lacking in torsional or lateral rigidity, but the carbon frame transmits significantly more trailbed vibration through to the rider. The bike feels more precise and pointy, and a bit more ‘lively’ as a result of this. It also feels harsh at times. As ridecount increased, this main difference cemented itself; the aluminum Warden smoothed out the harsh edges of trail noise, and I kept wanting to strap an NVH meter to the carbon. On the Shore, losing a bit of trail noise and harshness can be a welcome quality. The slightly dulled ride of the aluminum frame would have me reaching for it on shorter rides (sub 2 hours, so most riding around here in the winter), or the occasional shuttle. Given the overall pedalling performance of the suspension platform, headed out on a longer weekend ride, or if I knew my riding partners for the day were going to be fitter than my current fatness, I’m leaving every gram I can at home and taking the ~0.9lb lighter carbon frame - its noticeable grinding away up Old Buck.

Perry following Cooper.

“I can read the specs, Cooper. Do I pay the Carbon Tax or not, dammit.”

Well, who are you? And more importantly, how do you ride? Every decision you make bike purchasing is a sacrifice somewhere (for a grossly simplified version, see the “Cheap-Light-Strong” ternary plot).

Are you hammering out multiple days a week, signed up for burly XC races to get fit for the FIVER WORLD SERIES*? You might be a Carbon Warden. While I won’t pretend to know if this one is any faster descending, you’ll have some extra fuel in the tank at the top and the feedback and precision may come in handy when you’re pinned. It’ll also be easier to lift into your Tacoma.

*Our local Enduro series

Are you a ‘one bike quiver’ person, with some huge summer Epics planned? Those back to back 9 hour days in Revelstoke you have planned won’t miss 0.91lbs.

What’s the ‘carbon tax’, in hard numbers, and US dollars? 0.91lbs. $1,063. $2.56/gram. A five day Whistler Bike Park pass, with $643 left over for gas, food, beer, a bed, and $200 for your local trail association.

On the flipside, if the majority of your riding is short-ish, or you’re thinking really hard about whether or not the $1000 is worth it, it's probably not. I enjoyed the comfort and ride quality of the aluminum frame, and the weight won’t make much difference over shorter distances. Should you find yourself on Into the Mystic facing hours of suffering, it’ll get you there. You can also lose 415 grams off the system weight you’re dragging up the hill by spending some of the $1063 on kale smoothies instead of fish and chips.

Corners have begun appearing on the North Shore - and the Warden owners are pleased.

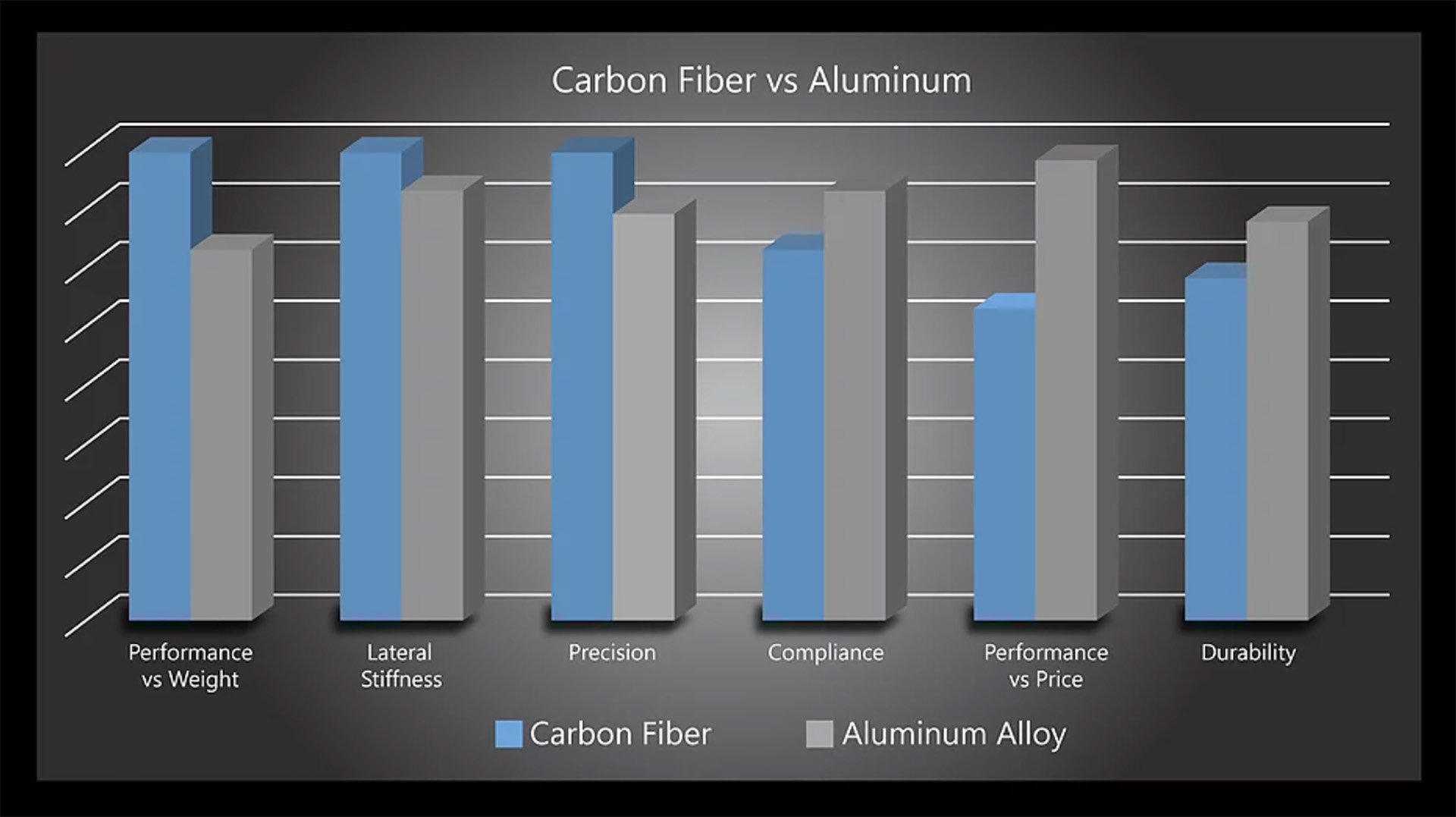

I was a fan and defender of the data Knolly presented when they switched to 157 Trail rear ends. I’m not a fan of charts that don’t have a Y-axis label, and are purely qualitative. This may as well be titled “Marketing Gooble”. I’d like to know how “Performance” was measured. And what “Performance vs. Weight” means.*

*Noel Buckley's response: That graph is designed to be used within the Knolly range to give customers some idea of the differences between alloy and carbon versions. When customers ask: "what's the difference between the Warden alloy vs. the Warden carbon frame?" we need to be able to give them some context of why they might want to spend an extra $1,000US on a carbon frame - or not. So while it is an unlabeled graph, it IS designed to be purely subjective and we're OK with this since it reflects how we at Knolly feel about the differences between our product and has nothing to do about us vs. our competitors.

Cooper on the left...

and Perry on the right.

I can think of reasons to buy each one. They really aren’t that different. It's up to YOU to decide which factors and sacrifices drive your decision. If I’m picking one to buy, I’ll take the aluminum. I’ve already got a carbon rocketship for big days, and the Warden would fit nicely into my quiver as a rowdy bruiser when the need arises. I live on the North Shore, where taking the edge off trail chatter is welcome comfort. But, a couple caveats. This choice applies to the Wardens, but the inherent complexities of aluminum and carbon manufacture means it doesn’t necessarily transfer to other frames. Also, both these bikes had high end spec; I’d ensure I had the high end dampers, clampers, and wheels before I threw down the Carbon Tax, if you happen score a large tax refund this year. As I said, the bikes aren’t massively different. The carbon version probably does have more “Performance” as the graph suggests but because of my current stable and riding habits, I wouldn’t pick it unless money didn’t matter.

We aren't really able to declare a winner considering the scope of our observations, but this does suggest that putting the priority on performance parts before deciding on frame material, is probably the way forward.

Comments

Alex D

5 years, 11 months ago

Wow, dudes.

Cam: I can't tell the difference. It climbs well.

Pete: Carbon is smoother. It doesn't climb well.

Cooper: Aluminum is smoother. It climbs well enough.

Kudos for having the stones to publish such conflicting observations. Sounds like it's an entertaining bike, but the choice of frame material is a toss-up.

Reply

Cr4w

5 years, 11 months ago

Amazing. Just goes to show how subjective this stuff is.

Reply

Cooper Quinn

5 years, 11 months ago

Its qualitative, for sure.

As is pretty much any test/review that doesn't involve a lab coat and test bench - and even many of THOSE are junk!

Reply

Cooper Quinn

5 years, 11 months ago

Support your local bike shop; don't just buy something off the internet based on reviews - they're inherently subjective and we're all human with different perceptions of the world around us.

Go test and demo bikes to find out what works for YOU. Use reviews to guide and augment your decisions.

Reply

Kieran

5 years, 11 months ago

Interesting. Perhaps its the rider not the bike!

Reply

Cam McRae

5 years, 11 months ago

So some of us are stiffer and some of us are more compliant? ;)

Reply

DMVancouver

5 years, 11 months ago

Nicely done. That said, Knolly has produced high-end alloy frames for most of its existence, aimed at the performance market, so it’s not surprising that the alloy bike rides well. I suspect there might have been more clear differences with brands like, say, Giant or Specialized, where the alloy bikes are geared toward those on a budget. This comparison says more about Knolly bikes than it does about materials.

I think what can be concluded is that it’s possible to make a good aluminum bike.

Reply

Velocipedestrian

5 years, 11 months ago

Perhaps that means it's time for a rematch with Santa Cruz, or another brand offering the 'same' frame in both materials?

Might require a custom parts build, I suspect few brands will be speccing Alu like Knolly.

Reply

Kenny

5 years, 11 months ago

Yeah I was going to say the same thing. I wonder if the gap is larger in the case of a company that is primarily carbon. Like a nomad cc or Bronson cc versus an aluminum one.

Reply

Cooper Quinn

5 years, 11 months ago

Agreed, it is 100% possible to make a good aluminum bike. Or steel.

Material engineering and manufacturing trump the actual material; there is no "best" material until you wrap some parameters around what you want.

IMO it wouldnt really be a fair test to pit a "cheap" alloy bike vs a premium carbon offering for the same reason you mention; it would say more about the manufacturing and design than material; apples to oranges.

Reply

Cam McRae

5 years, 11 months ago

Good point Cooper. Many brands are now producing two levels of carbon frame to hit specific price levels so it's likely the aluminum version is aimed at a specific price rather than the best performing frame that can be produced using that material.

Another reason why it would be difficult to reproduce this test

Reply

DMVancouver

5 years, 11 months ago

"IMO it wouldnt really be a fair test to pit a "cheap" alloy bike vs a premium carbon offering for the same reason you mention; it would say more about the manufacturing and design than material; apples to oranges."

If your budget is around ~$5000 and looking at non-boutique brands, you're likely faced with the choice of the aluminum frame with better parts or the carbon frame with a lower-end build. That comparison, while somewhat apples and oranges, would be interesting (e.g. Norco Range C3 vs A1, Specialized Enduro Comp with upgraded wheels vs. Enduro Elite, Giant Reign 1 vs Reign Advanced 1, etc.).

Reply

Cooper Quinn

5 years, 11 months ago

The article you're looking for exists!

(sorta, anyway)

But yeah, that's what I meant with, "Also, both these bikes had high end spec; I’d ensure I had the high end dampers, clampers, and wheels before I threw down the Carbon Tax,"

They'll have a much more, immediate/noticeable effect (IMO), and there's bigger 'performance' gains to be had by upgrading components if your bike comes equipped with under-performing parts than there is by swapping frame material. Assuming you have a good aluminum frame, with good geo and kinematics, anyway.

Reply

Primož Resman

5 years, 11 months ago

What i was thinking at the end of the article, given a 1000+ CAD difference in price between the two relatively same speced bikes, the difference in price could go towards a lighter wheelset and other similar components, to bring the weight much more inline and maybe even bring the performance of the ALU bike on a slightly higher level.

For me, carbon doesn't make much sense, aluminium is plenty good enough to make frames.

Reply

mike

5 years, 11 months ago

Devinci offers alloy and carbon , alloys are hand built in Canada. Carbon are off shore . Not sure if they are exactly the same frame spec wise . I know with my model in alloy does not fit the same water bottle as the carbon models do. As a machinist I get giddy over the precision required in fabricating an aluminum frame. Carbon is too paper mache IMO.

Reply

Michael

5 years, 11 months ago

Count me in as a Knolly rider that wishes for steeper seat angles (both actual and effective) and I'm not that tall at barely 5'8" riding a medium 27.5 Endo. Knolly's being fairly progressive use their travel pretty easily at the beginning of their stroke this makes for significant "extra sag" when climbing the steeps. I love the engineering in the aluminum frame; few alloy frames are as well engineered but I am looking forward to the next iterations with steeper seat tubes and a longer reach to accommodate. We've had slack seat tubes forever, its time for steeper, its much easier to use an offset post than it is to manipulate a frame or compromise seated cockpit by sliding the seat forward or handling by running a long stem to accommodate a wider range of people.

Reply

Shoreboy

5 years, 11 months ago

It looks like the Fugitive has started to go in that direction. ESTA is 76/75.5 degrees. That's about 2 degrees more than the Endorphin and Warden. No numbers given on ASTA but I assume they will probably increase by about the same amount. Fugitive is also significantly longer in the reach deparment than the Endo or Warden, so it looks like there is a slow migration to newer geometry.

Reply

Michael

5 years, 11 months ago

I know, pretty stoked about those changes. I’d happily move to the next gen alloy Endo if they follow suit. I suspect they will. I miss the industrial aesthetic in the suspension linkage that the Fugutive lacks but cest la vie.

Reply

Primož Resman

5 years, 11 months ago

It's quite obvious the ASTA numbers are just as horrible as any other of their bikes. Google Bird Aeris 145, that's about as much of a difference between ESTA and ASTA that should be allowed.

EDIT: interesting that they don't offer bang side on shots :)

Reply

Lynx .

5 years, 11 months ago

Great piece, kudos for printing the views even though they seem so polar opposite in some instances. Only reason I would ever consider carbon is for a major weight and stiffness gain, but doesn't seem to be the case here at all, then there's the durability when you "lay" them down on some proper rocks.

As to the 0.9lb weight difference even coming into the thought process because you want to pedal for long hours, nah, if you were talking wheel or tyre weight, but not something so static as the frame.

Reply

Cooper Quinn

5 years, 11 months ago

SOME carbon bikes likely have more significant stiffness gains (and some probablu habe losses!). In this case, theres maybe a bit of a difference, but its not massive by any means.

Re: weight. Well, sure. And I think a lot of peiple would consider 0.9lbs "very significant". But if you decide 400g doesn't matter here... Or here.... Or here.... And that part is also fine...

Suddenly you'll be on a bit of a monster, ya know?

No, its not unsprung rolling weight, but its not like were talking 15g.

But to my point above, if that doesnt matter to you, use that to guide your decision - maybe you're an aluminum Warden guy, and using that dough on a set of carbon hoops?

Reply

Lynx .

5 years, 11 months ago

I said nothing about any other part, just the frame, that's it. Don't understand the need to try and divert attention away from the fact that it's not a lot and dropping that $1K+ on a nice set of carbon wheels that will give you stiffness and precision where it's needed, while also probably reducing actual important, rotational weight in the possible 200-400g range makes much, much more sense.

Reply

Mammal

5 years, 11 months ago

This is great! And as others have mentioned, it demonstrates how subjective these perceptions are.

One thing that jumped out at me with the purely qualitative graph (and yes, a lack of y-axis says "I have nothing to say, stop looking at me for answers"). The qualitative measure of durability has aluminum ahead in the race. If I were trying to spin this successfully, I would have added 2 categories; impact durability and fatigue life (or durability). If I'm a nube, and I see carbon behind in the durability game, I'm running away from that material.

Reply

Cooper Quinn

5 years, 11 months ago

I (perhaps obviously) was not in love with that graph.

Having talked to Noel, I get why its there, as a response to trying to portray immeasurables to potential customers who aren't doing test rides and are buying online, but yeah, there's a lot of subjectivity and relativity which I don't love.

The fatigue life of aluminum is definitely a factor in some people buying decisions, as is the repairability of carbon.

And the flipside - would 'hard' numbers and data be more effective for most customers? Probably not.

Reply

JD

5 years, 11 months ago

If there were hard numbers (X% stiffer, Y% greater strength, Z% more "performance"...) then we'd all be here arguing about whether the lab test methods are representative of real world conditions, and talking about the "feel" of the bike being more than just the numbers... I don't think you can win either way! I think the graph is a useful visual for people to understand what Knolly thinks are the pros and cons, and to get them thinking about what factors the material choice influences. Unfortunately it also could be misleading, and there's really no way to justify even the relative rankings.

Reply

Cr4w

5 years, 11 months ago

A key factor not often mentioned is the non giving a shit factor. By this I mean that you're more likely to ride your alloy bike more aggressively and with less concern for its aesthetics or general treatment. When I switched from my last alloy bike (which was supposed by a summer test ride but I rode it for 4 years) and into really beautiful carbon bike, suddenly I was concerned about the bike all the time. As much as it was nice to have a really beautiful bike I'd rather save $, gain 1lb and not have to care as much.

Reply

Shoreboy

5 years, 11 months ago

I guess we could e-debate this until the cows come home. Until we agree on how Actual STA (not ESTA) is measured, you are going to insist the Endorphin has a steep ASTA and I am sticking with it being one of the slackest.

Reply

Vik Banerjee

5 years, 11 months ago

I explained how I am measuring my STA....from BB to middle of the saddle rails at my full ride height. That's the only STA I care about since that is the one that I use for climbing and most seated pedalling.

How steep the Endo is comparatively just depends on what bikes you compare it to. My point is not the comparison, but the fact that it is objectively steep and that steep doesn't make it better for everyone.

The fact that some other bike has a 90 deg STA, which is steeper than the Endo or some bike has a slacker STA is irrelevant to me.

Reply

mightyted

5 years, 11 months ago

I ride a warden and have demoed an Endo. My wife went for the endo.

The asta on the endo is steeper than on the warden. For me it makes for a tighter cockpit. I didn't relate to Pete's comments about the saddle position when climbing. I think it's pretty good. I would mention the warden design is 5 years old. Pete might be comparing it to more recent longer lower models like the Nomad? I'm not an mtb historian but might say that knolly has been placing there bb well back of the seat tube intersection for a while.

One observation I would make is how the front triangle on the carbon is better suited for a water bottle. And how the fugitives front triangle is the same in that regards. A change I suspect is coming to more of Noels bikes over the next few years.

My wife and I love our bikes.

Great article guys

Thanks

Reply

Pete Roggeman

5 years, 11 months ago

Hi Ted, I absolutely am comparing to bikes like the Nomad and other contemporary AM/Enduro bikes, but as I think we can all agree, no single geometry fits every rider. Yes, the saddle position on the Warden is 'pretty good' by my reckoning, too, but in a field full of bikes that exceed that level, without sacrificing elsewhere...well, that's part of my job to point out.

If you find something that works for you, that's the most important thing. However, for riders shopping for a new bike (or just looking to debate STA ad nauseum), the numbers don't lie.

Reply

mightyted

5 years, 11 months ago

I must admit I'm envious of the access you guys have.

Cheers

Reply

edmclean

5 years, 10 months ago

Carbon fibre reinforced plastic can be recycled to some extent but not to its original level of structural performance. It's becoming increasingly common to chop carbon fibre structures up and use the material as filler for plastic moulded parts. This is similar to the idea of glass reinforced nylon and results in stiff plastic parts.

As said above, it would be interesting to repeat the test with something like a santa Cruz nomad or a specialized demo, where it seems that there is a little more experience in using carbon fibre for frame construction.

Reply

Primož Resman

5 years, 10 months ago

It's actually rare not to have reinforced plastic, since you almost always needs more strength and less creep than pure plastic usually allows.

There are also guidelines with many different classes of products as to how much recycled plastic can be included in the final product and how many times a certain plastic can be recycled.

Reply

Vik Banerjee

5 years, 11 months ago

I have a Knolly Endo. I came off a Pivot M6 which is a lovely carbon bike. I noticed no frame material related differences in the ride. Obviously not apples to apples. I'd happily buy another carbon frame if it was significantly lighter than the metal version. But carbon frames that are as heavy as a quality metal frame and cost $1K+ USD more?...No thanks.

FWIW - I put a 1" setback dropper on my Knolly because I found the STA steeper than optimal for pedalling efficiency.

Reply

Primož Resman

5 years, 11 months ago

How tall are you? Because at ~800 mm of seat extension on a bike with a bent seat tube (last gen Reign) i hate how far back i sit over the rear axle. Bent or offset seat tubes are the worst and Knolly is one of the main offenders in this regard since, like, forever!

Mind you, this is not an issue for less tall riders (mainly M frame sized), could be an issue you described on S and XS frames, since you get too far forward, but it's just horrible for large seat post extensions on L and XL frames.

Reply

Bagheera

5 years, 11 months ago

I was wondering, when you're talking about "true STA", do you mean what's usually referred to as "actual STA" (the angle of the seattube) or the actual angle measured from your seat height to the BB? If the latter, those 68 degrees would be rather shocking.

Reply

Vik Banerjee

5 years, 11 months ago

On my Knolly Endorphin [similar geo] with a 1" setback dropper my actual STA was ~73.5 deg....measured from BB to center of saddle rails. My pants inseam is 33".

Reply

Cr4w

5 years, 11 months ago

Are you all femur? You might be the only person in history to find a Knolly seat tube not slack enough.

Reply

Shoreboy

5 years, 11 months ago

Yeah this is a first. Ive never heard of this complaint on a Knolly before.

Also, measuring as you have stated above is not ASTA, it is ESTA.

Reply

Vik Banerjee

5 years, 11 months ago

Nope: https://farm1.staticflickr.com/945/41210139194_3096d222f5_h.jpg

Not a Knolly, but it's the first photo that fell to hand I am definitely not the only person who buys setback droppers because STAs have gotten too steep.

Reply

Bagheera

5 years, 11 months ago

Sweet trail in the pic. It rarely happens that a pic makes me feel like climbing, but this one does.

Reply

Shoreboy

5 years, 11 months ago

I still dont get it. The Actual STA on an Endorphin is 69 degrees (according to the article on that other online bike site). One of the slacker bikes out there. Perhaps the offset you are using is compensating for some other variable that makes it feel more comfortable?

Reply

Vik Banerjee

5 years, 11 months ago

The Endo has a measured STA [incl offset dropper] that's 1 deg steeper than the bike it replaced.

Steep STAs are great for really steep climbing, but not the rest of my pedalling needs. Really steep climbing is only a fraction of my ride time so I prefer a more relaxed STA for that and I can slide forward on my saddle for the short time I am cranking up a wall.

I've noticed with the newest crop of steep STA bikes folks have started asking about setback droppers, talking about bending saddle rails from pushing the saddles back too far and noting they love the new bike for steep up and steep down, but wouldn't choose it for more pedally all mountain riding.

To your other point...your body doesn't know or care how the saddle to BB relationship is achieved, but it sure does know what's comfortable and efficient. So the only thing the offset can do is move the saddle backwards like a slacker STA would.

Honestly the fact that not everyone like steep STAs shouldn't be shocking to you.

Cam McRae

5 years, 11 months ago

Effective STA is based on a line from the bb to the top of the seat post with the saddle at a - - sometimes and average saddle height and (edit) sometimes a line parallel to the top of the head tube. The actual angle of the seat tube is not the same number on most dual suspension bikes because the seat tube is often interrupted and rarely mates with the centre of the bottom bracket shell. In this case the seat tubes meet the down tube well ahead of the bottom bracket producing a lower angle seat tube - so if your saddle height is above the median your ESTA will be lower than that suggested by the geo chart. Hope that makes sense.

Reply

Bogey

5 years, 11 months ago

The ESTA is generally measured at horizontal line that projects back from where the stack height is measured to. This is mostly useless IMO.

There are one or two manufacturers measuring it to a ‘’normal” fully extended seatpost height but I don’t believe they tell us what that height is.

Reply

Shoreboy

5 years, 11 months ago

Agreed. ESTA is mostly useless for all bikes that dont have a straight seat tube that directly intersects the BB junction. ASTA is going to tell you how 'slack' your seat tube is, not ESTA.

Reply

Cooper Quinn

5 years, 11 months ago

Its a useful measurement, the problem is that different manufacturers measure it differently, so its kind of un-possible to directly compare, as you point out.

Agreed that it is kinda useless at the top of stack.

Reply

Andy Eunson

5 years, 11 months ago

Plus when you take fork and rear end sag into account you get the real seat tube angle which may actually change going uphill if the rear suspension tends to wallow. Or for a hardtail gets steeper yet.

Reply

Bagheera

5 years, 11 months ago

Thanks for the reply (also to all others who replied). I'm familiar with ASTA and ESTA but the wording made me wonder whether he was talking about an ESTA measured at his seat height, which, as you mention, could be different from a geo chart. I think he meant ASTA, though.

Reply

Cee Cee

5 years, 10 months ago

What if we change the designation from actual seat tube angle to seatpost angle? The closer the seatpost angle is to the ESTA, the more meaningful the ETT. Taking crude measures from a 5010, I estimate that for every cm of saddle height above the horizontal ETT line, the actual top tube--measured from center top of head tube to seatpost axis atop saddle--increases about 4mm. I can see why manufacturers don't want to get involved in providing charts on this, but it's not that complicated to observe that the difference between seatpost and effective seat tube angle is more pronounced on a Warden than on a Meta 4.2, for example.

Reply

Primož Resman

5 years, 10 months ago

That would be a relatively good measurement, but you also have wildly different offsets to think about then.

Plus this is mainly an issue for taller riders, who get sat much farther to the back. It could be an issue for smaller riders as well, who effectively get an even steeper seat tube angle, but given the rotation of the main frame due to differing sag values the issue is less pronounced.

Speaking of sag and climbing, seating further back over the rear axle makes changes in sag while climbing again even more pronounced for taller riders, where the actual angle gets even more slack (because you set the sag with the bike being level).

I'd say for anything that has to be pedalled up the hill (this of course includes enduro class of bikes), the primary geometry considerations should be cockpit geometry while being sat down. We spend much less time descending to optimize purely for that compared to pedalling up the hill.

Then i wouldn't be surprised if having more or less the same weight distributions of front vs. rear would bring the effective ride quality comparing different sizes of frames more in-line with each other. Maybe that would mean a steeper seat tube angle for the XL frame, which would be then sagged lower while climbing, even longer top tubes, maybe even longer chainstays (but not the Norco way, where the move the BB forwards on larger bikes to lengthen them, thereby again decreasing the seat tube angle).

It might even mean different suspension geometries between sizes!

Reply

Cee Cee

5 years, 10 months ago

Agreed. Overly slack actual seat tube angles may introduce insurmountable weighting problems, as many angry commenters have remarked, sometimes in conjunction with the accusation that manufacturers are misrepresenting toptube lengths. I see Knolly has not provided an ASTA for geo of Fugitive. Judging from their 'technical data sheets,' Bird looks to have it better sorted.

Reply

Shoreboy

5 years, 11 months ago

As Cam said the imaginary line from the BB up to where it intersects the imaginary reach line is the effective seat tube angle (ESTA). Most companies take an average, some actually state the ESTA for each different size of bike. The actual seat tube angle (ASTA) is if you draw a line down the seat tube to the ground and then measure that angle. Knollys have their seat tube intersection well in front of the BB, so 68 degrees for a ASTA sounds about right.

Reply

JVP

5 years, 11 months ago

Interesting that Knolly says their aluminum is more durable in that chart. I've had almost all aluminum bikes fail at welds after 3-5 years of hard and regular use. I'm hoping carbon lasts longer, but I haven't had one long enough yet to know. Would be cool to sell (for cheap) a 5 year old frame instead of throwing it away.

Reply

Cooper Quinn

5 years, 11 months ago

Its also worth considering that oftentimes, carbon cracks/breaks are repairable. Which is important, especially if you're outside the warranty period.

But that delves dangerously close to the 'environmental' argument, which is something I'd rather not start at the moment, because I can already hear people lighting torches and sharpening pitchforks on both sides.

Reply

JVP

5 years, 11 months ago

Go for it. Pitchforks = clicks = new yachts for all you NSMBers that we all know are getting really, really rich doing this bike journalism thing.

Reply

Cooper Quinn

5 years, 11 months ago

With this on top of my paycheck for volunteering with the NSMBA, I'll be retiring to Monaco any week now.

Reply

damientheo

5 years, 10 months ago

I've had the same experience with aluminum. It fatigues to failure and even publicized as having a finite lifespan. Once it goes, it is not easily repairable (or at all) so then you need to buy a new frame and then you're probably past the price of carbon. Carbon is much easier to repair and today's frames can take a lot of impact- probably just as much as aluminum (or even more - see SC video).

Seems that carbon is more often the winner in both financial and possibly environmental terms (provided it's not a warranty trasher) when/if the frame does break.

Reply

Primož Resman

5 years, 10 months ago

Composites are not immune to fatigue failures. I'm beginning to wonder if there are any materials besides steel that have a fatigue limit (a stress value under which the material can handle unlimited cycles).

As for what they take, aluminium is strong enough (apparently) and light enough when designed correctly while being much, much cheaper. Which makes it good enough. Also, regarding repairing carbon, i'd personally think thoroughly as to what i would have repaired and what not. I would probably inquire about a crash replacement before anything else.

Reply

Moritz Haager

5 years, 11 months ago

When carbon started to appear more and more on the scene about a decade ago I really wasn't sold in the idea. Road bikes for sure but MTB? Way to many opportunities to sustain impact damage. Fast forward to 2017 and it seemed like CF really had become the primary material for frames suggesting the industry had figured this out so I bought my first CF MTB. So yesterday I was out on an epic old school XC ride and had an awkward fall at basically walking speed or slower when I got the front wheel stuck in a rut. The kind of fall I've had countless times in my riding career. Fell on my side and managed to break the seat stay on my bike. I haven't even got a full season out of it. Aluminum might have dented but it would still be rideable IMO. I think a MTB costing this much should be able to deal with these kinds of expected falls. It's what happens to most riders. If we are honest most people who can afford these machines won't be hucking big gaps etc but they will have many of these types of falls. It's left a really bad taste in my mouth.

Reply

Primož Resman

5 years, 11 months ago

I cracked seatstays on carbon frames by literally tipping over and the stay hitting a rock in one and a wooden ledge in the other case. On the other hand i dented and opened up a top tube with the shifter and had a cracked swingarm (banana style Meta), but that happened after 7 seasons of riding and the crack appeared on a weld on t he non-drive side. The brake side. Clear as chips as to what was the cause - cycles, with braking and suspension cycles combining in one single weld.

So yeah, i'm not much of a carbon fan, though mainly due to the price and marginal benefits given the price difference.

Reply

Pete Roggeman

5 years, 11 months ago

Hi Moritz, did the manufacturer stand behind the bike and at least offer a reasonable replacement cost?

Reply

Moritz Haager

5 years, 11 months ago

I'm still waiting to hear. Thing is even if they replace it, now I'm going to worry about it happening again, and I firmly believe I shouldn't. I am 45 and don't ride crazy shit anymore. IMO a MTB needs to be tough enough to withstand minor falls like mine. Sure, it can get scrathed, or sustain other cosmetic damage, but it should remain safe and rideable after the type of minor falls that are so common in this sport. Personally after this experience, even if they replace it for free I'm thinking of selling the bike and picking up a Knolly Fugitive or something similar in Al to replace it.

Reply

uberlounge

5 years, 10 months ago

I have snapped aluminum frames by riding through hard compressions (no fall and no impact), and I've dented aluminum frames on minor falls. So far my luck with carbon has been better and I have been amazed that some of the rocks thrown up into my frame left no mark at all. I guess I'm saying that seemingly "small" forces can cause significant damage, and large mechanisms can leave a frame undamaged. Everything breaks, just have fun and don't worry.

Reply

Moritz Haager

5 years, 10 months ago

Update: they are offering to sell me a crash replacement. While I'm not necessarily surprised, I am disappointed. I just don't think a bike costing 6k should break from what's essentially a tip over while at stand still. If it does then IMO 1. It's not designed well enough for its intended purpose, 2. It's the wrong material for its intended purpose, 3. The company should have a no questions asked replacement policy for at least one year from purchase, or 4. It's only realistic for those with very deep pockets who don't have qualms about buying a new frame on an annual basis. While I'm fortunate enough to be a high income earner I still cannot justify this kind of expense, never mind the hassle of being without a bike for a significant portion of our (Short) riding season in Alberta. I think I'll be selling this bike once I get the replacement and looking to go back to aluminum. Maybe NSMB could put together an article on high end aluminum bikes that rival the best CF rigs out there?

Reply

kaesy

5 years, 11 months ago

Interesting article and unsurprising findings. Design matters most; materials not much.

It would be great to see an article about real-world frame repair. It's often assumed that carbon can't be repaired, but after a major crash into a pile of rocks on Cypress broke a Scott Genius seat stay (not severed, but crushed from impact), Roberts Composites did a beautiful repair for $300, replacing the damaged section-- pretty cheap, and fast. No further issues.

After a decade on (mostly burly) carbon frames, with many crashes and impacts, that's still the only breakage I've seen. (Let's forget the early carbon XC dualies, Trek.) Carbon can be very repairable, just like any composite boat, auto panel, etc, and we should stop assuming that it's fragile and can't be fixed.

What would it cost to repair a bent/broken aluminum stay; could it even be repaired; where in the real world would you take it for repair; how long would it take? My Cove Hummer frame (Ti) broke at the downtube/head tube weld and into the downtube; Cove sent the frame back to Lynskey for (warranty) repair, where the broken tube was removed and replaced. And everyone knows you can have steel repaired; but where; what limits; how much?

Reply

Merwinn

5 years, 11 months ago

I think a large amount comes down to the legal risk a brand wants to stand behind for a repair vs. replacement. Perhaps Lynskey have the in-house welding expertise to mitigate some of that that risk, while others brands don't .

Reply

kaesy

5 years, 11 months ago

You're probably right that legal risk is a consideration; or the perception of risk; or both. But frames of all materials get damaged, and warranty might help but usually doesn't. Repairing a frame could/should be cheaper to the rider than replacing a frame, in many cases, especially when there are probably half a dozen new standards in place that mean a bunch of your parts won't swap to a new frame anyway. And faster than dealing with most warranty departments. And less wasteful. I'd be interested to know what repair options are out there.

I was pretty happy to have a $300 fix on a $3000 frame and get back on the trail in a couple of days!

Reply

Perry Schebel

5 years, 11 months ago

Roberts is fantastic. I had a carbon frame repair done a few years ago. It's unfortunate that most damaged carbon frames are going into landfill (or retired as wall art), when they're fully repairable. Seems there's good opportunity for a thriving repair industry. Retiring carbon frames before their time makes me feel extra ungood about the environmental impact of the material.

As to Moritz's concerns - I'm of the opinion that some carbon bike manufacturers are building too light for reasonable expectations of longevity (in regards to aggressive trail / enduro rigs; assumed fragility is an acceptable trade-off in the xc realm). Tubes with silly thin cross sections (ie, you can visibly depress with thumb pressure) that, while capable of handling typical riding forces just fine, can get holed by merely falling over onto a hard surface. carbon is light stuff, i'm sure the weight added to ensure acceptable impact durability wouldn't be *that* significant. of course, though you may end up with a frame that's significantly stronger than alu, the primary sales floor feature (lack of mass) is eroded.

That said, I think builders should be playing more to carbon's ability to create unique forms - unlocking design opportunities not possible with metal shapes - rather than re-creating alu frames in carbon and trying to convince us that a more fragile frame that's 1lb lighter is somehow worth a ~$1k surcharge.

Reply

Cooper Quinn

5 years, 10 months ago

"I think builders should be playing more to carbon's ability to create unique forms"

Of course you do, you design nerd.

(and, hey. I 100% agree with Bill Lear, "If it looks good, it'll fly the same." I'm always a bit disappointed when a carbon bike just looks like two triangles.)

Talking to a friend who designs such plastic-fantastics for us to enjoy, this person would LOVE to make carbon frames a couple hundred g heavier, but basically can't because "marketing" and "europe".

Without entirely agreeing with Verdone's assessment of why people are so focused on weight, its certainly one of the BIG numbers that people look at when assessing a new ride.

And, kudos to Knolly for caring about it a lot less than some.

Reply

Please log in to leave a comment.