Knolly Nuggets from Interbike

For the last few years at Interbike, Knolly has had a modest booth in the back corner of the exhibition hall. They’ve always been in the same corner, which makes them easy to find when it’s time for Noel and his gang to hand out the yearly edition of the Knolly shot glass and copious amounts of single malt. Everyone who’s anyone knows of this tradition and looks forward to it as much as a lap dance from the Goddess of your favourite strip club. Perhaps you can imagine my surprise when during the first day of the indoor show I ran into Noel wandering the aisles away from his booth. You do have a booth, don’t you Noel? “not this year, there’s no whisky either.” Whoa, what?! After a short conversation it became imperative that I arrange a second meeting with Noel to discuss all things Knolly.

The bright green Chilcotin on display at Interbike 2010

The bright green Chilcotin on display at Interbike 2010

Rewind back a year to Interbike 2010. The new all-mountain Chilcotin from Knolly was revealed at the Dirt Demo, and had plenty of enthusiastic riders checking out the green machine inside the expo centre. It was to be released to the public in March of this year, but the date came and went without the Chilcotin showing up. So what happened? Who better to give us the full scoop than Noel himself.

According to Noel, they were not happy with the version of the Chilcotin that was supposed to go to market in March of this year. Early this past spring, they set out to completely redesign the Chilcotin. The result is a bike that Noel sincerely believes to be the strongest and best-built Knolly to date. It’s also the first Knolly to come off of the production line in Taiwan. Okay, be honest – raise your hand if you just gasped. Four years ago, I would have raised my hand too. However, I was fortunate to be invited to Taipei near the end of 2007 to tour through some bike factories. It was a trip that opened my eyes. When I arrived back on home soil, I had dropped the negative stigma often associated with Made in Taiwan. One can easily argue the negative merits of overseas manufacturing when it relates to loss of jobs (for example) in North America, but one can’t argue with the high quality of manufacturing.

The new and redesigned 2012 Chilcotin

The new and redesigned 2012 Chilcotin

It wasn’t an easy decision for Noel and his crew to make. They’re big advocates of North American design and production. They’re also big advocates of the highest quality materials from which bikes ought to be made – materials that, according to Noel, are no longer available in sufficient capacity in North America. He was talking specifically about the aluminum tube-sets the frames are made from. In a very matter-of-fact way, he simply stated that in his opinion, Taiwan has the best vendors making the best products in the world.

The decision to move the manufacturing process overseas had been in the back of his mind since early 2010. I asked Noel about the process of choosing a vendor; what sort of criteria were they looking for? The prospect of trusting that the investment used to start searching will result with a perfectly matched vendor seems daunting to me. Noel’s comment reveals a glimpse of this process: “We knew that there were excellent facilities there, but finding these facilities is tricky and you have to make the right connections first.” An easier criterion to filter out candidates was the need for a factory that could deal with a small boutique customer like Knolly. After eight months of a lot of strategic searching, Knolly entered into a partnership with vendors who “are excited too because we have excellent communication and our designs are absolutely dialed when they receive them.”

Clean graphics, clean lines, and clean welds

Clean graphics, clean lines, and clean welds

Back to the 2012 edition of the Chilcotin… Many of the good things that Knolly liked about the original Chilcotin have been improved in the 2012 version. High-end modern hydro-formed tube-sets with double and triple butting are used throughout. There is now an E-type direct mount front derailleur and ISCG tabs. The bike goes from 150mm to 160mm travel, front and back. A single bolt will allow a geometry change from 67 to 66 degree head angle. Bottom bracket height is about 13.4 inches. The rear axle is 142mm x 12mm. Four sizes will be available (S, M, L, XL) across all of the Knolly bikes starting in 2012 (they have dropped the XS size and incorporated some of traits of the XS into the S).

One bolt to change the frame geometry

One bolt to change the frame geometry

I didn’t get an MSRP from Noel, but he says the cost won’t really change from the initial spec, despite moving to over-seas manufacturing. The reason for this is that although the actual labour costs are less (and the per-unit cost is less), there is a much larger front-end investment needed for the tooling, and the materials are more expensive (and substantially better, according to Noel). The first batch of bikes are on their way, and are all spoken for. But you shouldn’t have to wait too long if you’re looking to buy a 2012 Knolly Chilcotin. Just to note – the other models in the Knolly lineup are in the process of (or already have) moved over seas.

Linkage details

Linkage details

The final word on the build and ride quality will have to come later when we get our grubby little hands on a Chilcotin. For now, we’ll have to trust Noel when he says that the bike is much better, or as he put it: “the proof is in the pudding”. I noted the sincerity in Noel’s voice when he was describing how the move to Taiwan was the right move for the company and that the quality of the bikes is significantly higher than what they were able to produce locally. You’ll have to be the judge, but I’m willing to trust Noel. He is after all a fan of a nice cask-strength single malt.

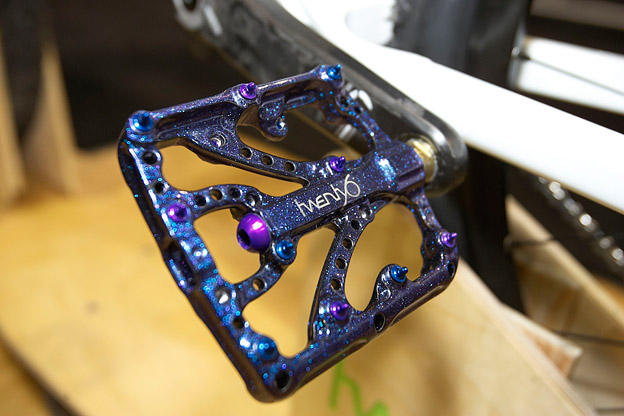

Sparkly new pedals from Twenty6

Sparkly new pedals from Twenty6

What about those purple glitter pedals?

Tyler Jarosz, the rider behind twenty6, has a new pedal for 2012. The Predatorpedal features improvements aimed at increasing foot grip and a bevy of well thought-out details. There is a reduction in surface area, yet the pedal is longer and wider than the Prerunner pedal. The reduction in surface area is supposed to result in more contact with the pins which are located at three different heights in the pedal. The pins are machined with a breakaway point that allows the top of the pin to break cleanly rather than be smudged into a deformed lump if you smash the pedal on a rock. The threads are also fully protected from the pedal surface ensuring there is never any damage to them. As per usual, Tyler provides a lot of finishing options.

We’re running out of photos of cute girls, so we have to start digging through the shots of desperation.

We’re running out of photos of cute girls, so we have to start digging through the shots of desperation.

Thoughts or questions about Knolly’s move to Taiwan? The new Chilcotin? Post them up here…

Comments

Please log in to leave a comment.